AAF Power

In demand

AAF International’s history dates back to 1921 when Bill Reed – a skilled engineer and entrepreneur – recognised that cleaning the air was crucial to the growth of society, contributing to the development of technology and the protection of human health.

He developed the Reed Air Filter, which was the first step in creating an international company that dominates the global air filtration industry. AAF clean air products and systems offer the most comprehensive clean air solutions available in the world. In fact, the company’s products are the industry benchmarks for quality and performance, from simple roughing filters and air pollution control, to gas containment removal and the highest efficiency filters used in the most stringent clean environments.

At the heart of its operations is the Power and Industrial Group, which supports the design, manufacture and installation of systems to protect gas turbine and other rotating machinery. The P&I division offers the most comprehensive global manufacturing capabilities in the air filtration industry, and each facility is specifically designed to manufacture and test the most complex clean air solutions. Additionally, each facility manufactures to the appropriate international quality and performance standards. Ultimately the company’s goal is to achieve excellence in each product it manufactures. AAF’s corporate quality policy describes its commitment as placing customer satisfaction and continuous improvement as the highest priorities. Therefore product quality cannot, and will not, be compromised.

James Ross, aftermarket business manager, describes the company’s main strengths: “The pillars which AAF has built its foundations on are our continued investment in skilled personnel and also product technology. Keep in mind that gas turbines are asked to operate in extreme conditions; we effectively evolved our range of systems to provide reliable, high performance in the harshest environments. Our main line of technology is proven in the marine sector, which is one of the most difficult environments, and we also have class leading products that function well in desert sandstorm type conditions.

“We are keen to let people know that we don’t only provide filtration products, we actually design, manufacture and maintain everything from the filtration system, and turbine enclosure to the exhaust, in a turnkey package. The biggest strength we have is ensuring we maintain our original fleet of equipment throughout its 25 year life and beyond. Our ability to work in the aftermarket, travelling to the customers who already have AAF equipment and providing after sales services, including upgrades, repairs and performance optimisation has been a key driver in the growth of the division. A benefit derived from this close relation with our customers, is ensuring we feed back problems or successes to make sure that our clients are continually getting the best out of their equipment.”

Another of the company’s important assets is its presence across the world. James comments: “As a global infrastructure, we are represented in over 60 countries, and it’s specifically in the oil and gas dense areas that we are developing support. Our HQ in the North East of England is supported by regional offices in the Middle East and the US, so specifically in touch with the oil and gas industry, we’ve regionalised the business in the areas where production is highest, making us a strong international player.”

Working closely with clients across these regions is vital to the type of service AAF provides. “Most of our projects are bespoke due to the nature of the oil and gas sector,” explains James. “The location of the gas turbine equipment within the oil rig is normally an area surrounded by ancillaries, and pipeline and steelwork, offering restricted working access. So we have to be very intuitive in terms of how we put the specific package together to make sure that once the equipment is delivered offshore it can be put into operation very quickly. We are always looking at how we can design modular services, which could be very small constructions or one single lift project, with a one-day installation. Either solution selected minimises any interruption to production.”

Working closely with clients across these regions is vital to the type of service AAF provides. “Most of our projects are bespoke due to the nature of the oil and gas sector,” explains James. “The location of the gas turbine equipment within the oil rig is normally an area surrounded by ancillaries, and pipeline and steelwork, offering restricted working access. So we have to be very intuitive in terms of how we put the specific package together to make sure that once the equipment is delivered offshore it can be put into operation very quickly. We are always looking at how we can design modular services, which could be very small constructions or one single lift project, with a one-day installation. Either solution selected minimises any interruption to production.”

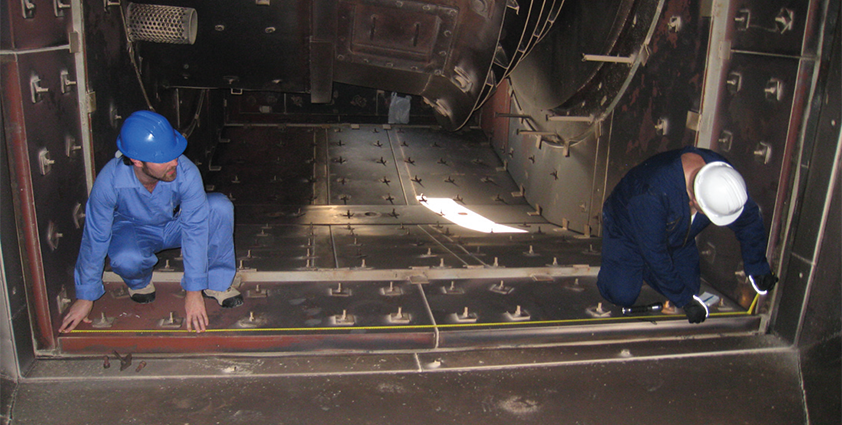

Established only three years ago, the field service team provides after sales and maintenance services. As James explains this is one of the fastest growing parts of the business: “I would say that year-on-year, the demand for field services has grown by over 50 per cent. A lot of the assets in the North Sea are around 20 years old now, and so obviously because of the environment they’re becoming very run down. We believe that we have identified a niche in the market because the equipment that surrounds a gas turbine is relatively specialist and so its maintenance is a specialist job too. It’s probably the fastest growing sector of our business and I definitely see it growing further.”

Another important area of growth is in engine performance optimisation: “The demand for high efficiency particulate air (HEPA) filtration is growing as our customers look for ways of guaranteeing gas turbine operation continuously without interruption through unplanned failure or to compressor wash. We have proven our HydroCel filter technology over the last ten years with results showing that engines can be protected absolutely from salt and contamination ingestion. This protection ensures greater availability of the gas turbine since it eradicates the need to take the engine offline for washing, reducing shutdowns from one per month to once per year. The financial gains to the operator through an enhanced production yield can often be tens of millions of dollars annually”.

Looking to the future James outlines the company’s growth strategy: “At the moment we are focusing on our existing customer base and growing our portfolio. We feel that we now have strong recognition with companies such as Chevron, BP, Exxon Mobil and Woodgroup and our plan is to develop those relationships further. We want to get the message across that although many people consider AAF to be a filtration company, in reality we can offer, among other services, maintenance, upgrades and gas turbine optimisation. We do feel that our services are in demand, so our next step is to raise their profile across our main markets.”

AAF Power

Services: Filtration services