Advanced Flange Isolation Kits Combat Corrosion

Fighting corrosion with exotics

Back in November 2011, two of the world’s largest manufacturers of flange isolation kits came together.

PSI (Pipeline Seal & Insulator Co Ltd) of St Neots UK and Pikotek of Denver, Colorado have combined manufacturing and engineering expertise totalling nearly 80 years.

GPT manufactures a wide range of engineered products for the pipeline industry and has a vast portfolio of products dedicated to sealing, isolating and connecting the world’s pipelines. A main focal point for GPT is assisting pipeline owners and operators to protect their assets in the fight against pipe and flange corrosion and to enhance safety.

Since the early days of oil and gas exploration and production, pipeline and flange corrosion has always been a major issue, costing operators billions of dollars a year. In fact, industry sources estimate the global cost of corrosion in the oil and gas industry to be in excess of $1.3 billion. For offshore facilities, some operators estimate 60 to 70 per cent of maintenance costs are directly related to corrosion issues.

Robert Colton, GPT’s Oil & Gas segment leader states: “Over the past 30 years, operating conditions in the oil and gas industry have changed hugely and have become more challenging not only from a production perspective and the complexities that brings, but also in terms of the transportation and refining of the highly corrosive media that is being extracted. We have found that the offshore oil industry in particular is continually pushing oil exploration to greater depths than ever before, which in turn leads to greater pressure conditions and harsher environments. Advanced technologies developed over many years have meant that drilling to exploit hydrocarbons is now reaching greater depths, thus producing a higher rate of production from domestic reservoirs. However, whilst deeper drilling increases the life of these wells and production, this comes at a cost in that the media can contain much higher levels of highly corrosive Hydrogen Sulphide H2s. As a result of these increasingly sour environments, GPT (PSI-Pikotek) has over the last 20 years, seen an increased demand for higher corrosion resistant alloys, which are utilised in its critical service flange isolation kits.”

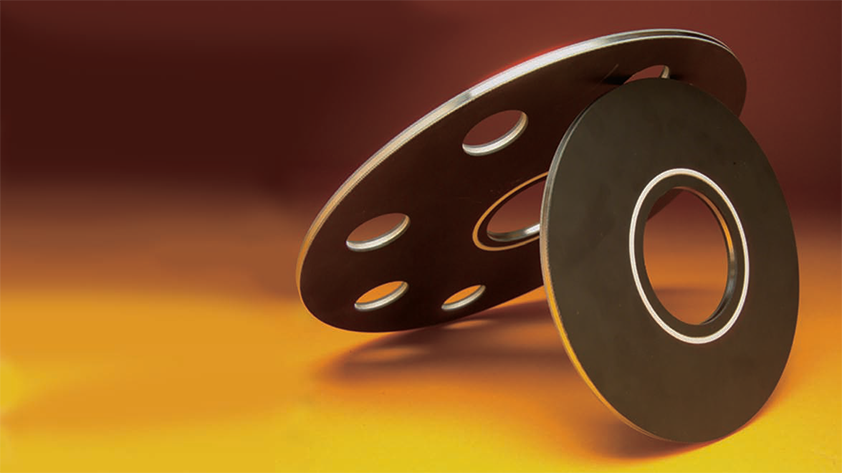

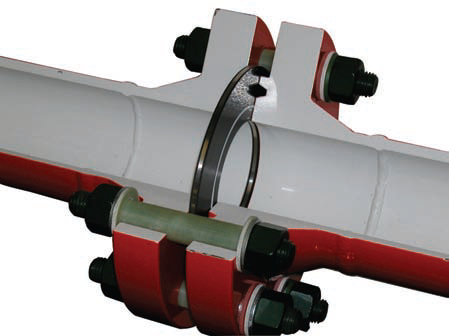

GPT manufactures its full range of flange isolation kits in two locations: Denver, Colorado, US and St Neots in the UK. These kits are made up of a number of vital components, which together ensure the integrity and safety of piping systems is maintained. Flange isolation kits are designed to seal and electrically isolate complete flange assemblies. By isolating the flanges, current flow in cathodic protection systems can be controlled and by eliminating metal-to-metal contact, galvanic corrosion cannot occur.

GPT manufactures a number of different flange isolation kits to suit varying applications and conditions. For critical service applications, the company manufactures systems that have a metallic central core, which has a high dielectric strength GRE retainer bonded to both sides so as to effect the electrical isolation. Historically, the core material utilised was generally a  stainless steel 316. However, over recent years there has been a growing demand for more corrosion resistant materials. GPT’s engineering teams in the UK and US have developed gaskets with a number of different cores, which have been required by operators to suit various applications. Such cores include 316L, Duplex, Super Duplex, Inconel 625, inconel 825 and titanium.

stainless steel 316. However, over recent years there has been a growing demand for more corrosion resistant materials. GPT’s engineering teams in the UK and US have developed gaskets with a number of different cores, which have been required by operators to suit various applications. Such cores include 316L, Duplex, Super Duplex, Inconel 625, inconel 825 and titanium.

Robert elaborates: “We are the world leaders in the design and manufacture of flange isolation kit technology and we expect to maintain our standing because we listen to the customer, understand their needs and invest heavily into research and development so as to meet their needs and maintain the integrity, and indeed safety of our clients’ facilities worldwide.”

With conventional metallic ring joint (RTJ) and spiral wound gaskets, there is always the opportunity for corrosion to occur. Galvanic corrosion can be a major issue with metal-to-metal contact. Different metals have differing potentials and when they come into contact with each other can cause a galvanic reaction that results in corrosion, which can be costly and dangerous. Also, as the RTJ and spiral wound gaskets do not match the flange bore, there is a small gap between the flanges in which deposits can build up, thus creating the potential for corrosion. GPT’s Isolation Gaskets match the bore of the flange and pipe schedules, which eliminates the risk of deposits forming and reduces the risk of flange corrosion. The whole range of GPT flange isolation gaskets have seals, which are fitted into machined grooves on the sides of the gaskets. This means that the GPT’s Flange Isolation Kits can be utilised in any flange type including RTJ. For RTJ flanges, the seal location is fixed between the RTJ groove and the bore of the flange thus rendering the groove redundant. The robust design and construction of the isolation gaskets means that they can withstand extremely high-pressures and are regularly used in ANSI flanges up to class 2500 and API 10,000.

GPT is also the manufacturer of the VCFS range of flange isolation kits, which were the first flange isolation kits in the world to be approved to API 6FB standards. The gaskets utilised in the VCFS design have a patented seal system that in the event of a fire will contain the media. This technology has become a standard offering for North Sea platforms and is fast becoming the norm for facilities worldwide. As with the standard range of critical service isolation kits, the GPT VCFS fire safe seals can also be manufactured with any core material to suit the application. GPT’s US and UK facilities now hold large stocks of laminated stainless steels, high nickel alloys and titanium cores to meet the ever-increasing demand for these products. GPT’s PSI and Pikotek brands are recognised globally and have been installed in many offshore and onshore facilities worldwide.

As it moves into the future, GPT is dedicated to continuing to grow and develop its product range, as Robert concludes: “GPT is well placed to achieve its vision and to continue to step up the standard for engineered pipeline solutions.” Todd Anderson, GPT’s Vice President adds: “As a global organisation, servicing industries that are both global and local, we are committed to provide regional support structures to best meet the demands of our customers. Our expertise in pipeline corrosion protection and integrity, product innovation, engineering excellence and safety truly allow us to seal, connect and protect the world’s pipelines. GPT has an aggressive growth plan and has made major investments to create a stronger foundation to support this growth. We are excited to work with the industry to meet the challenging pipeline needs. Along with other EnPro Industries companies, our passion and dedication toward excellence and improvement drive us to be number one in the world at meeting the pipeline industries needs. We look forward to working with customers in these dynamic areas.”

GPT

Services: Engineered pipeline solutions