Advanced Production and Loading ASA

The complete package

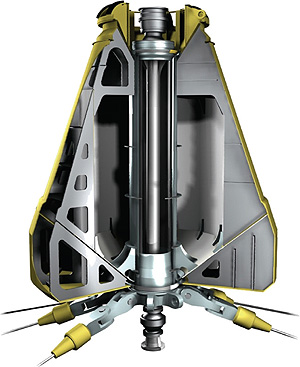

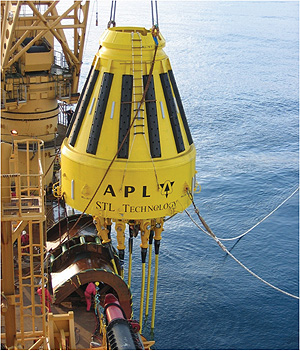

Established in 1993, Advanced Production and Loading ASA (APL) was founded to develop and commercialise submerged turret loading (STL) and submerged turret production systems (STP).

The business, which is recognised as one of the leaders in the sector, was founded as a response to the demand for increasing the operational limits of the offshore loading of oil and gas. The issue is  one that remains prominent in the industry today,and, as such, the commitment to producing the finest, safest and most flexible technology systems for offshore production and loading remains integral to APL’s ongoing success.

one that remains prominent in the industry today,and, as such, the commitment to producing the finest, safest and most flexible technology systems for offshore production and loading remains integral to APL’s ongoing success.

Presently in its 15th year, the organisation is acknowledged as one of the front-runners in the development, fabrication and sale of advanced systems for offshore production, with emphasis on storage and transport of oil and gas by vessels. Its work to date has been characterised by innovation and visionary design in all aspects of offshore loading, particularly SAL, STL and STP designs. APL’s headquarters are located in Norway, which alongside a number of global subsidiaries, accounts for the organisation’s 350 plus employees. Furthermore, its work has been the subject of much praise from those in the industry as well as critical acclaim. The most impressive of all the accolades was perhaps the Supplier Excellence Award by Phillips Petroleum, which came in 2002.

Such performance, quality and execution ofwork were always likely to earn APL a host of admirers. This proved to be the case when BW Offshore Limited (BWO) had acquired the company in June last year. BWO is one of world’s leading FPSO contractors and a market leader within advanced offshore loading and production systems to the oil and gas industry. The organisation has 1200 employees and has successfully delivered 12 FPSO projects as well as 42 turrets and offshore terminals – a record that speaks for itself.

Elaborating on BWO’s purchase, Andrew Clayson, managing director of APL UK,comments: “The real motivation behind the deal was the synergies between the FPSO operations of BWO and the technology of APL.” On the benefits that have come with the deal, he continues: “Since the acquisition took place, we have won a cascade of  substantial contracts. Perhaps the most prominent of all of them is the Chinoole project that we are carrying out in the US Gulf of Mexico, using APL technology. This is the first FPSO to be installed in the US GOM.

substantial contracts. Perhaps the most prominent of all of them is the Chinoole project that we are carrying out in the US Gulf of Mexico, using APL technology. This is the first FPSO to be installed in the US GOM.

“We are also operating an FPSO on the Mexican side of the Gulf, which is called KMZ. Furthermore, the group has continued to win a number of contracts in the liquefied natural gas (LNG) industry. Recent examples include the Neptune project in Boston harbour. They are just some of the examples of the type of contracts we have secured in the 12 months since the acquisition, and they help keep the group particularly strong. Other FPSO projects recently awarded include Peregrino for Maersk Petrobras, Basker Manter for Anzon and Tupi for Petrobras.”

The liquefied natural gas that Andrew speaks of is a natural gas, primarily methane, which has been converted to liquid form for ease of use or for convenient storage. Components such as water, helium, dust and hydrocarbons are removed to achieve liquefaction, following which the matter is condensed at close to atmospheric pressure. This reduction makes it more costeffective to transport in circumstances where pipelines cannot be used. Furthermore, when pipeline methods are not economical, cryogenic sea vessels or cryogenic road tankers can transport it.

“We will continue to play a big part in the LNG industry as there is an increasing amount of work concerning production and loading systems, which is a key part of our technology offering. There is the scope for us to grow considerably in this sector,” Andrew says. And, as he explains further, it is APL UK’s ability to develop total systems and solutions that has seen the company enjoy an extended period of prosperity: “Because of the way the industry is going, the strategy has been to offer the complete package. Increasingly, the oil companies are looking to buy complete systems with turnkey capabilities for the ship and mooring systems. We are also involved in projects that re-use APL systems such as West Don for Petrofac that will use SAL first deployed on Arclmore.”

The business has also benefited from the success of APL UK’s installation systems company, which has won numerous admirers, and – more importantly – contracts. This has been achieved through its expertise in hook-up, installation and, in some cases, equipment removal at the end of field life.

Prospects, you would imagine, the company is more than capable of turning into real business. Looking forward, Andrew concludes: “There will be challenges, such as securing the right people who have enough experience and know-how. There is also pressure to complete work on time as well as political issues in areas like the former Soviet Union, which can delay projects. But there are also significant territories like Africa, which is buoyant, and Brazil, which is huge – we’ve just secured our first project there. We are very positive, there is an awful lot of work we have done that will bear fruit and a great deal of further business to be won.”

Advanced Production and Loading ASA (APL)

Industry Offshore loading and production systems