Airpack BV

The perfect package

Dutch based Airpack BV is active throughout the world in the manufacturing of tailor-made and turnkey packages for the oil and gas industry.

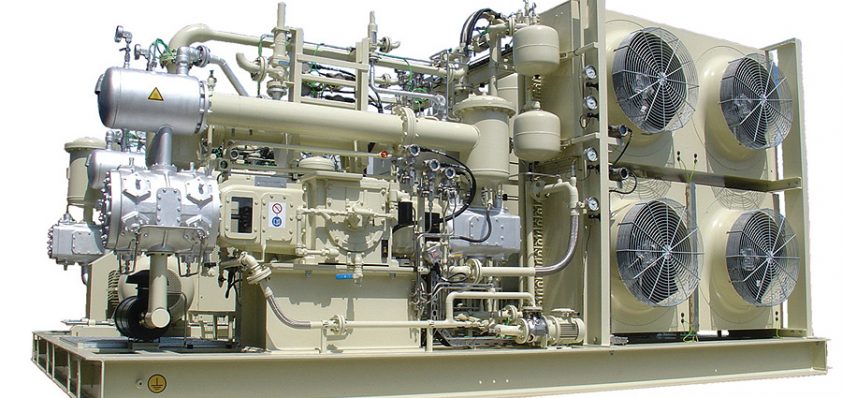

The company designs, manufactures and tests all installations according to customers’ specifications, and its product portfolio includes air compressor packages, dryer packages, nitrogen generator packages and gas compressor packages.

Marketing manager, Stevie Riedeman, introduces Airpack: “We were founded in 1978 by Mr. Warnar in Zierikzee, which is a small town in southwest Holland ideally located between the ports of Rotterdam and Antwerp. Since then we have expanded into an internationally-operating oil and gas package manufacturer, having supplied over 5000 packages so far across the world. More then eighty per cent of our business is offshore, concerning platforms and FPSO’s for example.”

Marketing manager, Stevie Riedeman, introduces Airpack: “We were founded in 1978 by Mr. Warnar in Zierikzee, which is a small town in southwest Holland ideally located between the ports of Rotterdam and Antwerp. Since then we have expanded into an internationally-operating oil and gas package manufacturer, having supplied over 5000 packages so far across the world. More then eighty per cent of our business is offshore, concerning platforms and FPSO’s for example.”

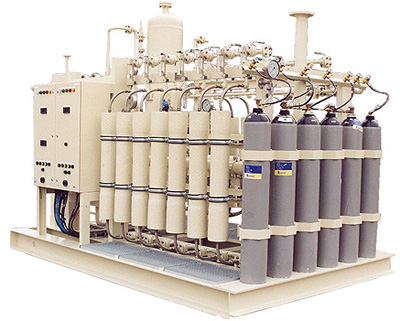

Discussing Airpack’s offering, Stevie adds: “For our nitrogen generator packages we use a membrane type nitrogen generator. Airpack has packaged according to specifications from amongst others Shell, Total, KOC, ONGC, Aramco.

“We specialise in enclosures, so our packages are suitable for extreme environments from desert to arctic conditions, and we concentrate on ATEX requirements, so we can do everything that a standard compressor manufacturer cannot deliver. Not only that, but we cover after-sales as well – maintenance, start-up and training all comes as part of the package, provided by our own team in our office as well as onsite.”

The organisation has progressed considerably from its humble beginnings and Airpack has recently completed the construction of a new office, featuring an eye-catching display of refurbished and rebuilt compressors that Mr. Warnar has collected over the years as a small exhibition. Commenting, Stevie says: “We’ve developed from operating in a small building to a large building where all the offices are more spacious. Our facility includes three big manufacturing halls that are equipped with all the necessary tools to manufacture our installations. Everything is well maintained state-of-the-art equipment, and we are ISO:9001 certified.

Aside from this development, Airpack has been undertaking work on a large project in Kazakhstan, as Stevie reveals: “One of our latest projects is a gas booster station that we’re supplying to boost into a 39 kilometre long pipeline. We transport the gas all through the pipeline using a 1 MW gas compressor. Most items are already onsite or have been delivered in the past fortnight. As we speak our maintenance team is over there to assemble the whole package, and then erect the whole structure before starting it up. In the coming months we have two more nitrogen projects and  three air and gas compressor projects coming up.

three air and gas compressor projects coming up.

Attracting new business comes relatively easy to Airpack, having built a respected reputation within the industry, partly thanks to its strategy of using local agents throughout the countries in which it’s active. “Our main focus when we enter a new country is to establish contact with a local, well known company, mostly one that is in the same business and, therefore, knows its way around the industry,” Stevie says. “That company will then help by being the local presence for customers to approach, and then it will forward all the information to us so that we can provide sales support from our office here in the Netherlands.”

Perhaps owing to this approach, Stevie says Airpack has weathered the storm of the recession with success thus far: “The market for us is very good; our sales manager is in Asia at the moment for four different projects. We’re not feeling the effects of the crisis at Airpack currently; we have more difficulty finding skilled people to work for us than finding further business to keep our company alive. To tackle this we have a third party communication company that helps us to find the right people through the appropriate media channels, usually newspapers, and we also look for new recruits and agents at fairs and exhibitions.”

Airpack is enjoying such a strong position that it has been able to launch a subsidiary and seven months ago it started a daughter company to target the oil and biogas sector and specialise in developing a new system to clean up these gases BVto make them usable for energy production by removing the H2S and CO2 from oilgas.

In thinking about the future of the industry and Airpack’s offering, Stevie comments: “The demand for nitrogen generator packages compared with instrument compressors will most likely increase in the coming years, because we see that the membrane types we use, and the fact that we’re able to supply very compact machines, are a very sought after product combination. Especially in the FPSO business where ships don’t have a lot of space. Hence why we’re seeing that the nitrogen part of our product line is growing and developing rather quickly. As a company, it’s important that we continue growing and innovating.”

Airpack BV

Products: Custom made oil and gas packages