Aker Floating Production

Plain sailing

Aker Floating Production, part of the Aker Group of companies, was established in 2006 with the purpose of owning, operating and chartering out a number of converted tankers equipped for offshore oil, gas and LPG production and storage.

Still a new business, Aker Floating Production aims to target the midrange market for floating production, storage and offloading (FPSO) with its fleet of vessels, converted Suez-max tankers named ‘Aker Smart’ 1, 2, 3 and 4.

Still in its infancy, the company was listed on the Oslo Stock Exchange in 2006, and today is headquartered in Oslo, Norway. The business is using the considerable strength and experience of the  Aker Group in developing its fleet of ‘Smart FPSO’ vessels, the first of which will be completed for first oil offshore India first quarter of 2008. When complete, the Aker Floating Production fleet will predominantly operate in benign, deepwater regions, and the capabilities are expected to meet the requirements of approximately 80 to 90 per cent of eligible FPSO projects in the company’s target deployment areas of South America and Mexico, West Africa and South-East Asia.

Aker Group in developing its fleet of ‘Smart FPSO’ vessels, the first of which will be completed for first oil offshore India first quarter of 2008. When complete, the Aker Floating Production fleet will predominantly operate in benign, deepwater regions, and the capabilities are expected to meet the requirements of approximately 80 to 90 per cent of eligible FPSO projects in the company’s target deployment areas of South America and Mexico, West Africa and South-East Asia.

Svein Olsen, CEO at Aker Floating Production elaborates on the business’ formation, and its aims and strategies for moving forwards: “We established the company in March 2006, with the intention of gaining contracts for operations by the beginning of 2007. We have focused on building up the business for the long-term, and are taking our operations very seriously. Once our vessels are operational, we are targeting benign areas such as South America and Mexico, West Africa, South-East Asia and India.”

Svein admits that being part of the Aker organisation will benefit the business considerably: “The advantage of being part of Aker is that there is a vast amount of technology and experience available, which enables us to operate at the forefront of the market and to deliver a package that will be very attractive to our customers. Being part of Aker allows us to draw on some very attractive resources, and help us in the market.”

The company is currently developing its FPSO fleet, converting three Suez-max tankers purchased in 2006 into its ‘SMART’ FPSO design. The tankers, the Polar Alaska, Polar California, and Oriental Tiger have a combined storage capacity of 1.3 billion bbls, and are in extremely good condition. The Aker Smart 1 is currently under conversion at Jurong, being made ready for operation at the Reliance MA Field, the Aker Smart 3 is presently operating as a crude oil storage tanker for Koch Inc. offshore Malaysia, whilst the Aker Smart 2 was recently delivered to the company, in May 2007.

In developing the vessels, the company is responding to the current increase in demand for FPSOs in the market. There are presently 118 FPSOs operating across the globe, and the recent increase in offshore drilling activity, including the influx of new deepwater drilling rigs and exploration plans, means that there is a considerable backlog of fields awaiting FPSO and subsea availability. In addition, there are more mid-sized operators in the market, and the near 100 per cent utilisation of FPSO fleet in the industry has led to a limited sector capacity.

Furthermore, the company’s market analysis indicated that there have been 109 offshore projects identified by March 2007 and more than 50 FPSO opportunities through to 2010. Additionally, during April and May 2007 there were between six and ten enquiries for FPSOs in the industry, indicating that the extension of existing FPSO contracts will severely limit the influx of redeployment.

Svein elaborates: “The oil and gas sector can be divided into three main segments – the top, middle, and lower tiers. The top end of the market consists of the major players, such as SPM, MODEC, Saipem, and more recentlyBergesen and Prosafe, whilst the middle tier includes companies such as Fred Olsen Production and ourselves, aside from Bergesen and Prosafe. We forecast that there  will be a significant rise in business in the middle tier in the coming years, and there is no doubt that there will be considerable opportunities, and demands from major customers.”

will be a significant rise in business in the middle tier in the coming years, and there is no doubt that there will be considerable opportunities, and demands from major customers.”

Svein admits that one of the biggest considerations when forming the business, and approving the development of the company’s vessels, was the current lack of manufacturing capacity: “There are many new developments happening at the moment, which would ideally be produced very quickly, but the contracting, manufacturing and supply sectors are very restrained.

“Additionally, many more rigs are coming online currently, which will certainly accelerate new developments,” he continues. “The main challenge will be the supply, resources and manufacturing industries. Consequently a number of companies, including ourselves, are building on speculation. However, we have scheduled for the development of FPSOs through to 2010 because we believe so strongly in the market.”

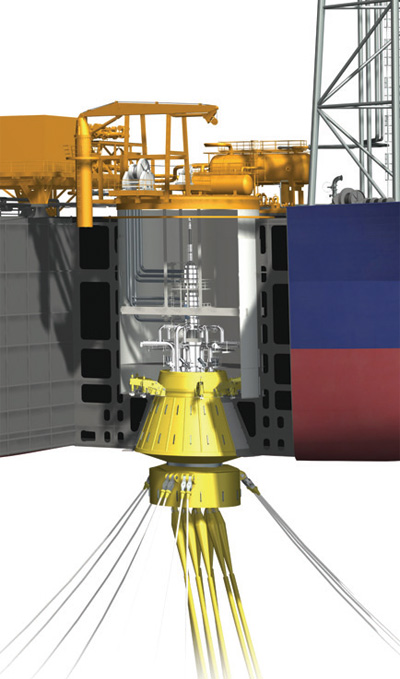

Despite being only a year old, the business has already signed a major contract with Reliance Industries Ltd. for its development in the West Indian Ocean. The project, which will produce its first oil in the first quarter of 2008, will have a gas injection capacity of three million cubic metres per day, and a gas export capacity of nine cubic metres per day. Situated off the West coast of India, the Reliance Field’s subsea facilities include well X-trees and controls, infield flowlines and subsea manifolds. The field will be operational for up to ten years, but has a potential lifetime of 15 years.

“We recently signed the contract with Reliance. It is an exciting project that is in very demanding, harsh environments, including cyclonic weather conditions,” says Svein. “It is due to produce first oil in 2008 in water depths between 1100 and 1400 metres. When fully operational it will produce up to 60,000 barrels of oil per day.

“Being part of the Aker Group benefits us in projects such as Reliance as we can use the vast resources available to provide a complete package, including pulling in the subsea facilities,” he continues. “Aker is providing Reliance with a total solution, including christmas trees, flow lines, subsea umbilicals and risers. We have taken overall responsibility, which is quite unique in the sector, and will serve to make us more attractive to the industry.”

In addition to the Reliance project, Aker Floating Production has several other prospective opportunities suitable for Aker Smart 2 and Aker Smart 3. There has been a great deal of interest for the combination of Aker SMART FPSOs and subsea equipment from Aker Kværner Sub Sea AS. In the meantime, Aker Smart 3 has been on a storage contract with Koch Inc since 20 October 2006. The initial contract was for 180 days. The customer did exercise the option to renew the first of two additional 90-day periods after expiry of the initial term. Koch Inc has expressed an interest in entering into an extended contract for the vessel, until the time it would be required at yard to start the FPSO conversion.

Since its establishment, little over a year ago, Aker Floating Production has developed its range of services, and consequently its reputation in the sector considerably. The company will continue to provide an attractive, valuable service to the sector by building up its resource basis with a long-term view, providing a competitive edge through its ability to include entire subsea facilities, and offering the availability of fast-track field developments. Svein concludes: “We have built up a strong organisation, and we will continue to grow organically. There is little doubt that the market is growing, and that there are a lot of opportunities entering the picture. We are confident in the current situation, and are consequently going to build the next vessels on speculation, so that we are able to provide the most attractive package to our clients.”

Aker Floating Production

Industry: Offshore oil and gas FPSOs