Allseas

Pipe dreams

Allseas is a major offshore pipelay and subsea construction company, operating specialised vessels that have been designed inhouse.

Over the past two decades it has gained international experience in all types of offshore and subsea construction projects, supporting clients in the conceptual design stage as well as offering its services for project management, from engineering and procurement to installation and commissioning. Rather than restricting itself to available technology, Allseas develops new techniques and applications wherever necessary, sometimes taking chances as part of its firm ‘no guts, no glory’ philosophy.

President Edward Heerema outlines the innovative company’s credentials: “Founded in 1985 as an offshore pipelay company, we work throughout the world and are always first with new technical  solutions. The big international oil companies, as well as a number of state oil companies, are our clients. We pioneered DP pipelaying – pipelaying on dynamic positioning – with the building of our first pipe lay vessel, Lorelay. Laying pipelines on DP was novel at the time as positioning of the vessel was done by anchoring. The advantage of DP is that in congested areas where many pipelines are on the seabed, we don’t have to place anchors. When laying pipelines moved into deeper water from the mid-1990s, we found that we had an even bigger advantage in being able to lay in unlimited water depths since anchoring becomes problematic beyond approximately 330 metres.”

solutions. The big international oil companies, as well as a number of state oil companies, are our clients. We pioneered DP pipelaying – pipelaying on dynamic positioning – with the building of our first pipe lay vessel, Lorelay. Laying pipelines on DP was novel at the time as positioning of the vessel was done by anchoring. The advantage of DP is that in congested areas where many pipelines are on the seabed, we don’t have to place anchors. When laying pipelines moved into deeper water from the mid-1990s, we found that we had an even bigger advantage in being able to lay in unlimited water depths since anchoring becomes problematic beyond approximately 330 metres.”

Ever since it began its first project in 1986, Allseas has executed numerous pipelay and trenching contracts. The scope of projects has ranged from straightforward pipeline installation jobs to contracts involving design, installation, engineering, procurement, fabrication and large subcontracted scopes for diving, dredging and rockdumping. Edward says Allseas’ projects vary considerably depending on the surroundings for each job, and its work is becoming more challenging: “The environment differs for each project because in the world there are areas where the sea is very calm or shallow, so requirements are easier compared with work we carry out in the North Sea or in extreme water depths in the Gulf of Mexico. Oil and gas is generally being discovered in increasingly hostile areas that are more difficult to reach – Arctic areas are remote, for example – and some areas can also be politically unstable. This presents many challenges and makes our work even more difficult.”

Allseas’ fleet consists of six ships, each suited to the company’s differing projects and tasks. “We already had Lorelay when we built Solitaire between 1994 and 1997,” states Edward. “Solitaire is the biggest pipelay vessel in the world with extreme depth capability and weight of pipe capability. She’s very long and has a high lay speed because she has many stations in a row on which we can work. Another of our vessels is Audacia, which falls between Lorelay and Solitaire in terms of size, and which was completed just a few months ago.”

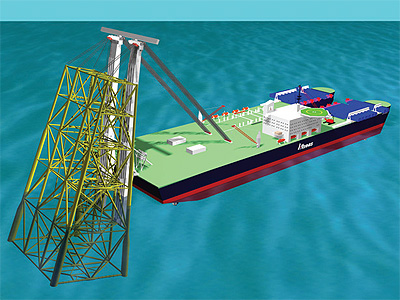

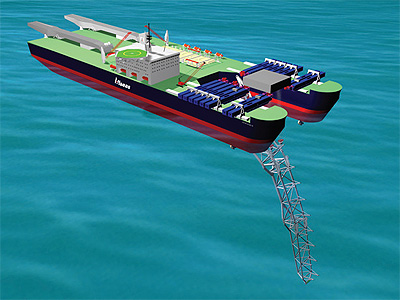

Updating its impressive fleet is a key concern for Allseas, and a new ship is in the pipeline. “At the moment, we’re preparing for the construction of a very large vessel,” reveals Edward. “It’s a  combined platform, installation, decommissioning and pipelay vessel that will be involved in installing and removing large platforms. Construction is going to be a big challenge because it’s a very large undertaking technically, as well as in terms of management and erection. We’re aiming for it to be operational by 2011 and are currently negotiating its building contract with a number of shipyards in Korea and China. We have already ordered the large machinery for the vessel, as those pieces of equipment have long delivery times, so we have made a full commitment to the development.”

combined platform, installation, decommissioning and pipelay vessel that will be involved in installing and removing large platforms. Construction is going to be a big challenge because it’s a very large undertaking technically, as well as in terms of management and erection. We’re aiming for it to be operational by 2011 and are currently negotiating its building contract with a number of shipyards in Korea and China. We have already ordered the large machinery for the vessel, as those pieces of equipment have long delivery times, so we have made a full commitment to the development.”

Edward says that, besides focusing on improving its fleet, Allseas is working on a subsea project that will come to fruition later this year: “We’re installing a complex subsea development on the east coast of India, which is a massive project consisting of many short lines in deep water. Offshore work will take six months and will continue until late in the Spring of 2008.”

When undertaking such projects, safety is a vital consideration in an industry where accidents are taken extremely seriously. “Health and safety is very important in our industry because the energy sector seeks a good reputation in this field,” explains Edward. “People tend to hear about the odd incident, which can be misleading as most operations are very clean and safe, with few accidents. We prioritise safe working, as do our clients, and are very concerned about even the slightest injury, which is why we have such a good safety record.”

Allseas’ aim for the future is based on progression through overcoming challenges to exploit its prominent market position, as Edward outlines: “Many contractors besides us have built new ships and the market of pipelay vessels is being flooded with newcomers. Recently, business has been excellent because the price of oil is high, which has allowed many oil companies to begin developments that were previously deemed too costly, so we’re reaping the benefits, but this could change with the many new vessels coming into the market. We’re looking to cement our status as an important international pipelay contractor and become a platform installation and decommissioning contractor as well.”

Allseas

Products / Services: Constructing and installing ocean pipelines