Amarinth: Innovating Pumps with 350+ Years of Expertise

Raising the bar

Having operated in the pump market for well over 100 years, the closure of Girdlestone Pumps in 2002 left a notable gap in the UK’s manufacturing market.

However, within this Oliver Brigginshaw and Steve Buckley saw an opportunity for a business that would continue the quality work offered by the former employees, and thus Amarinth was born. Initially the business concentrated on the UK market, but soon expanded overseas where it now achieves between 70 to 80 per cent of its turnover today.

Within the first two years of trading Amarinth moved beyond simply providing its own range of interchangeable pumps, to design and introduce a new pump series’ to the market. At the forefront of this is its range of API 610 11th edition pumps, which have been successfully launched in both horizontal and vertical variations.

Managing director Oliver elaborates: “From my perspective I am always trying to look ahead at the next thing. We are trying to build the company in a sustainable manner by focusing strongly on one range at a time, whilst looking ahead to what products will be required in the next few years. The other notable aspect is that we are utilising a combined industry experience of over 350 years, with many of the original employees from the former company joining us at the start. As such, we have been able to take this knowledge and combine it with the latest computerised simulation technology such as FEA & CFD to help design the best possible range of pumps for the market.”

Amarinth pumps are today found in general industrial, chemical and petrochemical applications. Crucially, the company offers engineered-to-order solutions, which are tailored to fit the exact requirements of its customers. “Our primary strength is our agility,” highlights Oliver. “We are a company that is able to react quickly to clients’ needs and in some cases have even delivered products before our competitors have completed a quote. We are also able to offer shorter lead times than a lot of others in the market, and for the oil and gas industry that is vital due to the costs of operational downtime.”

One of the more specialist activities that Amarinth is currently involved in is low carbon emission solutions in association with the Carbon Trust. Whilst this funding was unfortunately pulled three quarters of the way throughout the project, Amarinth has continued to finance it regardless, which business development director Alex Brigginshaw is keen to emphasise: “Our plan is to develop a high efficiency pump on a commercially viable basis hrough the design and manufacture of impeller efficiency. We have completed key stages of the project with both the software and initial prototype stages concluding, and are now looking at further prototype testing to support our findings.

One of the more specialist activities that Amarinth is currently involved in is low carbon emission solutions in association with the Carbon Trust. Whilst this funding was unfortunately pulled three quarters of the way throughout the project, Amarinth has continued to finance it regardless, which business development director Alex Brigginshaw is keen to emphasise: “Our plan is to develop a high efficiency pump on a commercially viable basis hrough the design and manufacture of impeller efficiency. We have completed key stages of the project with both the software and initial prototype stages concluding, and are now looking at further prototype testing to support our findings.

Oliver continues: “What we are trying to do is develop processes whereby you can design a pump exactly as the customer wants it. Within this, we have to find ways of making the planning and tooling equipment flexible enough so that you can actually cast the raw components to the specifications of this bespoke design. The first step to achieving this is that our designers are able to design the pumps much faster than traditional lead times, which is a commercial benefit. The second aspect is how we create patents that are flexible enough to enable us to fine-tune them with each individual product.

“From our perspective, a lot of our customers are facing stricter requirements in reducing their carbon footprint and therefore products that enhance this are of greater interest. In this sense, if they are running a pump at 20 per cent efficiency but can increase this by five to ten per cent through our equipment, it will translate into significant energy savings.”

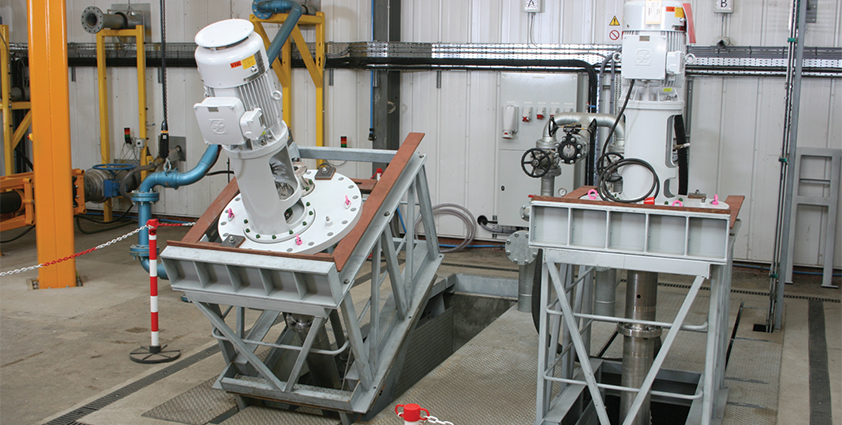

As Amarinth has continued to grow, so each year it has reinvested in order to sustain this. This has proven vital to the business as this year it has seen its income treble – a level of growth it would have been unable to cope with was it not for this ongoing investment into factory space. Alex highlights some of the capabilities offered by Amarinth’s recently unveiled new pump testing facility: “The original plans for this facility were drawn up two years ago and we have spent this time designing the hydraulics and efficiency. Now unlike the majority of manufacturers in our industry, our new hydraulic test bay gives us the capability to test pumps up to four times as quickly. This increases our ability to meet the very aggressive lead times currently seen in the industry, and at times gives us a further edge on the competition.”

The other prominent activity within Amarinth is identification of its focus for its next product range. This is something the business looks at every three to five years with great effect in order to continue to grow, whilst maintaining efficiency and profitability. “Our engineering expertise and technical capabilities help to inform what the next products are going to be, and how these will compliment what we already offer. At present we are undergoing substantial activity around this as part of an ongoing project, going through analysis and research around entry to market for between five and eight significant product types,” explains Alex.

“We try to specialise in things that clients find it difficult to source or manufacturers struggle to produce, and find ways of making them easier to manufacture and commercialise. As oil and gas production gets harder and faces new challenges such as the presence of sulphur, we see customers looking for more guaranteed engineering solutions and this is where Amarinth excels,” concludes Oliver.

Amarinth

Products: Pumps