Applus RTD: Pioneers in Non-Destructive Testing and Asset Integrity

Committed to excellence

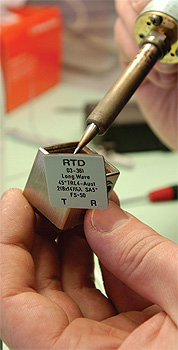

Applus RTD is an international company specialised in non-destructive testing (NDT), inspections and asset integrity management.

The company provides a wide range of NDT services and inspections stretching from specialised pipeline testing, on-stream monitoring and scanning, to detail inspection, data management and integrity management. In addition, Applus RTD offers a number of specialised services in the area of probe production, radiation protection, and training.

Applus RTD is an independent operating division of the international Applus+ organisation – a concern that is active in the fields of inspection and certification services for a diverse range of industries – from food and construction to automotive and climate technology.

Applus RTD is an independent operating division of the international Applus+ organisation – a concern that is active in the fields of inspection and certification services for a diverse range of industries – from food and construction to automotive and climate technology.

Today’s Applus RTD, with its headquarters in The Netherlands, started life in 1937 under the name of RTD (Röntgen Technische Dienst). From its early beginnings, RTD embarked on pioneering work in industrial x-ray testing. The company has continuously developed innovative concepts that have grown and diversified into the integrity solutions that help keep today’s chemical, oil and gas, and storage industries, as well as conventional nuclear power stations, operating safely and productively.

Applus RTD can provide an exceptionally wide range of testing technologies – both conventional and advanced techniques, and also tailor-made solutions. In the field of NDT&I, the technologies employed include radiographic, ultrasound, penetrant, magnetic and visual examinations. Technically advanced methods of NDT can also be provided which have been developed from conventional techniques. A key factor for the success of Applus RTD recommendations is the expertise of its inspectors. They determine exactly what is examined and where, how frequently, and the best method to use. They then interpret the data obtained and from this, make conclusions and recommendations.

Irrespective of the technique used, the key objective is to establish whether imperfection (such as lack of fusion) or degradation (such as corrosion) have occurred. Depending on the size and scope of the problem, a statement regarding safety and projected remaining lifetime of the object can be made. This information will help Applus RTD to recommend the necessary repairs to be carried out during routine maintenance, or for action to be immediately taken in the case of a potential hazard. During the construction of new vessels or pipelines, testing focuses primarily on weld quality.

For project related needs, advisory services are available from Applus RTD. Services include details on how inspections and maintenance can be effectively aligned with current legislation and  regulations, and also what sort of degradation can be expected, plus an associated maintenance schedule. Specific maintenance programs are also developed that will save clients a lot of time and effort, particularly when insufficient expertise is available inhouse.

regulations, and also what sort of degradation can be expected, plus an associated maintenance schedule. Specific maintenance programs are also developed that will save clients a lot of time and effort, particularly when insufficient expertise is available inhouse.

In the field of industrial radiography, Applus RTD’s considerable experience with radiation protection means solutions are not just limited to practices with ionizing radiation. Highly trained and experienced radiation safety experts are available to support clients in a variety of industries ranging from scrap metal to oil and gas exploration, as well as from the use of ionizing radiation in industrial process control to medical applications. Needless to say, clients are always advised to minimise radiation doses and to meet statutory obligations.

At the heart of Applus RTD’s activities lies the reporting of testing results. The services provided may typically begin by the selection or development of the optimal testing method. Measurements are then taken ‘in the field’ and a report compiled. For new constructions, this can lead to approval or rejection of a single weld or even a whole installation. Applus RTD aims at the provision of immediate reports, without the traditional waiting times of days or even weeks. In this way, efficiency can be enhanced and costs reduced – but never at the expense of safety to people or the environment.

As mentioned above, a key area of Applus RTD’s approach is a focus on health, safety, quality and the environment (HSQE) – to such an extent that all employees and the company itself are qualified to handle a wide range of projects and assignments, in many different sectors. All procedures are tailored to the specifications of clients, government bodies and certifying authorities all over the world. The company also works in close collaboration with those authorities in order to remain abreast of the latest requirements and knowledge, wherever in the world they may apply.

Applus RTD has built up a sturdy basis in the area of non-destructive testing and inspection (NDT&I) and the collection of data related thereto, data management and inspection services. With a strong reputation built upon innovation, technology, and properly trained and client-focused employees, Applus RTD is one of the prominent players in the international NDT&I and Asset Integrity Management market. This market is fragmentary, characterised by a great many small and medium-sized NDT&I companies per country, but also with players with varying backgrounds as competitors. The market potential differs per country and is linked to the size of certain industries and the energy sector. Applus RTD is amongst the largest international players in the more than 20 countries in which it operates. In fact, Applus RTD is an international company, operating in all continents.

Against a background of more than 70 years in NDT&I operations, Applus RTD has gained an ability to develop customised solutions to enhance clients’ process performance and assets integrity. The company’s flexibility, whatever the challenge or working environment, also helps ensure tailor-made client based solutions are provided and promises are kept.

Applus RTD

Services: Non-destructive testing, inspections and asset integrity management