Axiom Engineering Associates

Maximising assets

Now celebrating its milestone tenth anniversary, Axiom Engineering Associates Ltd is a company whose success has far outpaced its early projections.

Indeed, from a founding staff of just one mechanical and one materials engineer, the business now numbers 32 with typically three new personnel taken on every year.

“Our idea was to put mechanical and materials engineering services back into the small chemical plants of the time, which once had support from the likes of Imperial Chemical Industries (ICI), but saw those services disappearing. Individually we have a broad experience in these types of plants, which means that we can offer our clients an understanding of their problems from an operators point of view, as well as a practical hands-on approach to finding a solution,” begins Dr René Hoyle, co-founder, and principal materials engineer.

Careful and proactive management of assets can have significant benefits including extending the lifetime, reducing downtime and increasing productivity, and understanding failure. Today Axiom Engineering Associates is largely contracted by the petrochemical, oil and gas, and storage industries, but the transferable nature of its skills means it has also worked for a unicycle manufacturer and ice cream factory in the past. “It doesn’t matter if someone is making widgets to go in beer cans or the beer itself, we can help them identify what’s going wrong with their infrastructure,” notes Dr Hoyle.

“There are three main facets to our business; inspection, materials engineering, and mechanical engineering. The model we quote is that our inspectors will find any problem, our materials engineers will understand what that problem is in terms of what is causing it and the likely outcome, and the mechanical engineers will assess if repair or replacement is necessary. So the client gets a complete knowledge service for any problem from a single source. We can follow a project the whole way through, or provide any single component of that service so it’s a very flexible offering in that sense,” he continues.

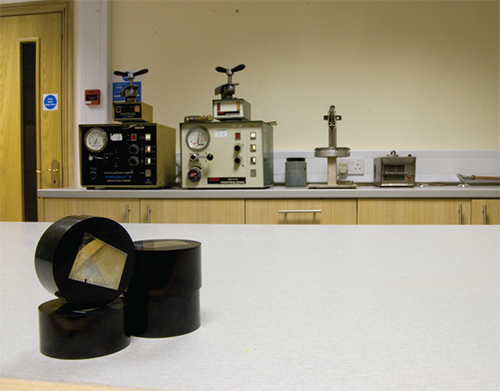

Often the starting point for Axiom Engineering Associates’ client relationships is the failure of an asset, whether it is a pressure vessel, tank, pump, lifting equipment, or other parts of site infrastructure. Through analysis and testing at its fully equipped laboratory, the company can identify the root cause of failure and advise on how best to rectify it. Likewise, only by understanding the degradation and the impact of running conditions on this can future failures be prevented, and Axiom Engineering Associates can use this data to prepare a programme of focused inspection, maintenance, and investment.

Often the starting point for Axiom Engineering Associates’ client relationships is the failure of an asset, whether it is a pressure vessel, tank, pump, lifting equipment, or other parts of site infrastructure. Through analysis and testing at its fully equipped laboratory, the company can identify the root cause of failure and advise on how best to rectify it. Likewise, only by understanding the degradation and the impact of running conditions on this can future failures be prevented, and Axiom Engineering Associates can use this data to prepare a programme of focused inspection, maintenance, and investment.

As an UKAS-accredited inspection body, the company also carries out statutory inspections according to regulatory requirements. “Today’s economic climate means many customers are not prepared to invest in new assets, instead opting to keep the older ones going for longer,” says Dr Hoyle. “This generally means that they require more inspection to ensure ongoing fitness for purpose and assessment of degradation, which fits well with our combined materials and mechanical engineering expertise.”

One example of where all three facets of Axiom Engineering Associates’ capabilities have come into play is the inspection of storage spheres. “We have been looking at a number of those for various clients that are using them to store liquefied gas,” explains Dr Hoyle. “One of the biggest challenges here is preparing the assets for their periodic inspection as they have to be emptied and de-gassed to ensure that it is safe for entry, and then internal scaffolding constructed to carry out the inspection.

“What we have been able to do is carry out a non-invasive inspection, so although the sphere has to be emptied and de-pressurised, we can do the inspection itself from the outside. Instead of just assessing ten or 15 per cent of the welds, this means we can actually check 100 per cent. This is achieved by a deep understanding of the history of the item, the materials of construction, the welding detail, and any likely defects that could cause problems. The cost savings of inspecting the assets from the outside as opposed to inside are astronomical, with an up to 90 per cent reduction in the six figure budget,” he adds.

Given the overlap and interaction between Axiom Engineering Associates’ inspection, materials, and mechanical fields, the company is now in the process of establishing a new division that brings all of these together. Titled ‘Asset Integrity Management’, this department takes a step back to look at a site as a whole and identify the areas that are the most critical or pressing concerns. Having this wider view means that clients can focus their investment in the right places to deliver the appropriate outcome.

Another change in the business is the intention to open one or two additional offices alongside Axiom Engineering Associates’ current headquarters in Stockton on Tees. Primarily this is aimed at increasing the company’s inspection offering with a localised service in key areas. “Inspection tends to be quite geographically sensitive because there are so many inspection bodies around, meaning it is not always viable to supply personnel into regions where there is a local offering.

“We are therefore looking to potentially open an inspection office in the central belt of Scotland around the Grangemouth area, and another in the south-east of England near the Thames Estuary. These services will then be supported by the materials and mechanical expertise at Teesside to provide the full solution cycle,” concludes Dr Hoyle.

Axiom Engineering Associates Ltd

Services: Asset management