Baker Hughes: Leading Eco-Friendly Drilling Fluid Solutions

Liquid assets

Supplying many of the major names in the industry, Baker Hughes Drilling Fluids is dedicated to providing the most effective, efficient and environmentally friendly range of drilling fluids on the market.

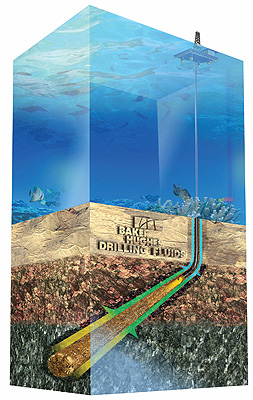

The company, which is a division of Baker Hughes, designs drilling and completion fluids as part of an overall drilling and well plan, to ensure maximum productivity and minimum wellbore damage. The business has offices based around the world, covering all of the key oil and gas exploration regions.

Arild Fjogstad, district manager at Baker Hughes Drilling Fluids in Norway, recently told European Oil and Gas Magazine more about his company’s operations: “Here in Norway we are a very  integrated part of the total Baker Hughes family, and within that organisation we can seamlessly cover all of the different aspects of drilling fluids solutions. This means that we provide a broad range of drilling fluids, including the necessary completion fluids and drill-in fluids, and all of the associated chemicals, pumps and equipment needed for the drilling and completion. Additionally, we offer environmental services, which involves taking care of, and recycling waste from the drilling process.

integrated part of the total Baker Hughes family, and within that organisation we can seamlessly cover all of the different aspects of drilling fluids solutions. This means that we provide a broad range of drilling fluids, including the necessary completion fluids and drill-in fluids, and all of the associated chemicals, pumps and equipment needed for the drilling and completion. Additionally, we offer environmental services, which involves taking care of, and recycling waste from the drilling process.

“Working for a global business such a Baker Hughes means that one of our main strengths is the excellent systems and products that we can provide to the local region,” he continues. “Furthermore, we have good integration with the other Baker companies, which allows us to share resources and knowledge to provide a far more effective, efficient solution to the end-user.”

Arild elaborates further on Baker Hughes Drilling Fluids’ global presence: “Baker Hughes is a leading global supplier of drilling fluids, completion fluids, and fluids environmental services, which covers a wide range of services related to waste management and treatment. The company has its headquarters and main R&D and technology centre in Houston in the US, and is based in all of the major oil and gas producing areas around the world.

“In terms of structure the company is divided into various regions, and in Norway we are part of the Europe, Africa, Russia and Caspian (EARC) sector, which has a technology and R&D centre in Aberdeen in the UK for localised product development and adjustment. We provide a broad selection of oil and water based drilling fluids that can cover all aspects of drilling. For example, we have standard and high performance water based fluid systems, such as our Performax product, which is designed to obtain results as close as possible to oil-based drilling but be far more environmentally friendly. Our oil-based range covers all from low temperature applications through drill-in fluids to high pressure, high temperature applications.”

In Norway Baker Hughes provides the full range of drilling fluid products, including completion fluids, drill-in fluids, oil and synthetic fluids, water based fluids, and environmental services. Arild explains: “In Norway we have been very active in developing a number of new technologies and products. This includes a great deal of work into the use of lubricants in the drilling industry, which has enabled our business to carry out projects on a number of high profile wells where the lubricants have enabled longer drilling times that were previously not possible, and have improved the overall efficiency of the operations.”

Furthermore, the company has developed Fluids Environmental Services (FES), which is a specific business that provides unique, specialised solutions to drilling clients. With a portfolio of products that includes solids control equipment, waste treatment, cuttings handling and disposal, Baker Hughes provides services that satisfy all of the global regulations for drilling waste. “We have had some very interesting developments in FES in recent years,” says Arild. “It allows us to take care of cuttings and waste from drilling, treat them locally, which saves a great deal of transportations costs, and recycle as much as possible.”

The company’s reputation in the industry means that it is the first choice for many of the leading drilling companies, and ensures it is involved with some of the industry’s largest projects. Erik Berg, business development manager at Baker Hughes Drilling Fluids in Norway explains: “We cover the Scandinavian sector of the EARC region, which consists of Norway, Sweden and Iceland,  and we work with all of the major clients operating in Norway. There are six major operators in Norway that we are currently working with, and among those is StatoilHydro and also Shell, which we have been co-operating with on its Ormen Lange project.”

and we work with all of the major clients operating in Norway. There are six major operators in Norway that we are currently working with, and among those is StatoilHydro and also Shell, which we have been co-operating with on its Ormen Lange project.”

Arild elaborates: “Ormen Lange is one of the major high profile developments currently in Norway, and we are supplying the full range of drilling fluids for the entire project, working very closely with Shell. To enable successful drilling operations at the site we have provided all of the drilling fluids, including specific reservoir drilling fluids and completion fluids, together with filter cake removal to ensure full productivity at all times to meet the high demands. We are very pleased with how our products have performed, and that have helped to achieve the phenomenal performance figures to date.”

In addition, the company’s drilling fluid lubricants have been used highly successfully by StatoilHydro at its Troll wells since 2005. Baker Hughes’ LUBE-622, a lubricant designed to reduce torque and drag in most water based muds, has provided improved drilling at the site, virtually eliminating large torque variations and lowering peak frequencies. The use of LUBE-622 has allowed drillers at Troll to slide into the hole beyond 11.480 ft without rotation. Furthermore, the use of Performax at Troll has resulted in significant performance improvements, including larger, drier cuttings than offset wells, improved borehole conditions, improvement of the longterm stability of drilling, and a 30 per cent reduction in dilution rates.

With the current market conditions being so favourable, Arild expects further opportunities for future success: “The market is very positive at the moment, and with the oil price close to $100 per barrel it creates a lot of activity and pressure in the industry. One of the biggest challenges for the industry will be to hire and train people quickly enough to meet demand. In terms of drilling fluids, there will still be a continued focus on environmentally friendly fluid systems, together with more development into high temperature products.”

Concluding, Erik sees no reason why Baker Hughes Drilling Fluids cannot continue to be a leading player in the industry: “Based on this we believe that we will continue our growth pattern as part of an increasing market, and that the technology that we offer will contribute to this growth and success significantly. Of course it is a challenging market, but we feel that we are in a good position, and that the experience that we have gives us an excellent advantage.”

Baker Hughes Drilling Fluids

Products: Advanced drilling fluids