Bearward Engineering: Global Leader in Industrial Radiator Innovation

Comfort control

Built upon decades of experience and heavy investment in technology, the Wabtec owned company, Bearward Engineering Ltd is one of the largest producers of industrial radiators in the world.

Founded in 1958, the business has been subject to enviable growth each year, and today operates out of a 40,000 square metre site in Northampton, UK. Supplying to the world generating set market, as well as supplying radiators for pumping and construction equipment, off highway, and other specialist equipment sectors, the company manufactures over 35,000 radiators a year with a turnover of £50 million.

Delivering into an industry that has seen increasing requirements in the reduction of noise and emissions pollution has ultimately led the business into placing great emphasis on innovation and technical expertise. Leading the way for the industry, it has developed a new range of sectional radiators, providing customers with the most advanced range of cost effective material, backed by worldwide and immediate after sales support. The applications and installations of the products are many and varied, from engine mounted power modules, to purpose designed low airflow, high-pressure reserve units for high acoustic applications. The result of this is that Bearward manufactures a complex range of radiators to cool engines from 500 KW to 3MW, including conventional jacket water radiators and water/charge-air configurations.

The company works closely with a large customer base that includes many of the main manufacturers in the power generation and construction market such as Caterpillar, Cummins, MTU, Mitsubishi and SDMO. Recognised as a leader in innovation, the success of the business is attributable to a combination of modern thinking and a base of traditional experience, as UK sales manager Matthew Eggleton explained in his previous interview with European Oil and Gas: “Bearward has a number of old-school engineers, combined with modern technology, which allows us to be very quick to bringing to market new designs and bespoke applications. We have developed a product, which allows on-site serviceability for any size of engine, and which is also designed to eliminate the failures associated with thermal expansion within cooling systems – this is our innovative sectional core solution.”

Belonging to the Wabtec Group, the business benefits from the ability to expand globally, setting up facilities in the local regions as it does. By enabling local serviceability and manufacture, the total cost of the product can be reduced. As part of the cooling division within a bigger organisation, Bearward has the ability to share technology and resources with sister companies, such as Young Touchstone and Unifin. Whilst the biggest threat to Bearward is the many lower cost producers of cooling systems, which are coming to the forefront on a global scale, it is the company’s trusted sectional product and global manufacturing ability that ensures it can keep such threats at bay.

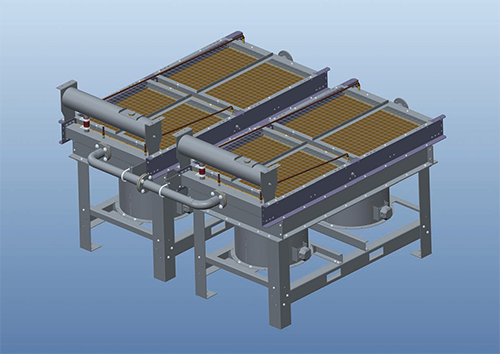

Ultimately the success, which Bearward Engineering has experienced, is a result of the huge benefits that its sectional radiators bring to end users for all markets. The sectional cores principally split one large cooling surface into many smaller modules, and the sectional product is designed in such a way that they can be individually removed whilst the cooling system remains in situ for maintenance or replacement. In essence, a cooling system that is maintained will provide superior cooling performance against one that is not.

With Bearward’s design, section removal can be completed by hand without the need for heavy lifting equipment and in circumstances of critical applications or sites; spare sections can be kept locally for quick changes. The sectional core removes all gasket joints associated with traditional cooling systems, and is designed to float within rubber seals removing the thermal stress to the cooling surface and isolating from heavy vibration. If a radiator is damaged, sections can be replaced on site making repairs much quicker and easier, additionally assisting cleaning if the radiator is operating in dirty conditions.

Renowned globally for its customer service, Bearward remains focused on its clients beyond the point of purchase, offering its comprehensive world-wide aftercare service. As part of its fast and efficient response to all service and repair issues on an international level, all parts are supplied with full warranty promoting the quality and reputation the company has worked hard to build. Boasting state-of-the-art R&D facilities, which are continually sharing data within the group, the support given to new developments is at a top level. Some of the company’s most recent introductions are the aluminium sectional radiators that have a direct cooling performance and dimensions to the copper brass sectional product.

Manufactured with the aid of the latest automated processes, quality is absolutely consistent, and Bearward’s sectional radiators give the highest levels of process control. Beyond the continuous and targeted developments of the product line, the company maintains a clear focus on the future. Its strategy is destined to ensure that the next five years will be as positive as the last few decades, aiming to keep a heavy focus on pushing its global presence, setting up local sub assembly and service locations, which effectively complement and support its continually improving portfolio.

Bearward Engineering Ltd

Services: Manufacturer of industrial radiators

Issue 122 July 2015