BIS Salamis: Leading Maintenance & Inspection Services for 40 Years

A strong heritage

As BIS Salamis approaches its 40th year the company looks back on a proven track record as a leading international services contractor, providing integrated multi-disciplined support services and maintenance services to clients throughout the energy, petrochemical, industrial and utilities sectors.

In the last year alone the company has continued to grow and build upon these core fabric maintenance and conventional inspection capabilities, as well as developing a new emphasis on specialist inspection and integrity services delivered through the BIS Inspection division. BIS Salamis is also exploring other specialist cleaning and architectural services, which are executed across a range of long-term contracts, along with more ad-hoc specialist projects, primarily directly for oil and gas operators.

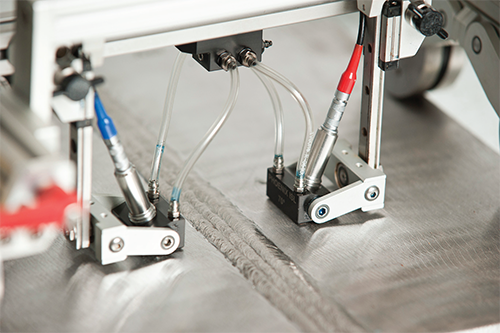

As to the reasons behind the company’s industry leading status, operations director Nigel Lees is in no doubt as to what sets BIS Salamis apart from its competitors: “It’s our people,” he says simply. “BIS Inspection has invested heavily in competency assurance, which assesses whether a technician has the right level of skills, experience and knowledge to be able to perform their job accurately and in accordance with company procedures. This process also identifies any skills gaps that can be bridged through coaching by technical staff or by providing accredited training. The focus for 2012-13 will be to ensure that technicians are assessed in all disciplines and in developing assessment for specialised NDT techniques.

“The competency system is essential for BIS Inspection in support of maintaining the ISO17020 accreditation, but most importantly it provides assurance to the client that the work our technicians do is efficient, accurate and that results can be relied upon. BIS Inspection was the first NDT inspection company in the UK market to introduce a competency system that used a third party expert to assess competency. This gives us the distinct advantage of having a mature system in place which re-assesses personnel,” he continues.

Another area of increased activity for BIS Salamis is the decommissioning market. As well as many small, bespoke projects the company has notably been involved in the decommissioning of Shell’s Inde field. Aware of further potential developments within this market, Nigel highlights how BIS Salamis has been pulling together its capabilities into a single focused offering: “We have strengthened our resources to support increasing activity in the decommissioning arena – in particular we have a greater business development focus and bear decommissioning in mind in all recruitment and selection activities. We are therefore able to offer potential clients a greater breadth and depth of experience and knowledge, as well as continuity of personnel as assets move from their late life stage into decommissioning.”

In particular, demand has been high for the preliminary decommissioning studies required when an asset is to be decommissioned. These help operators to understand the details of the asset and its conditions so they can look at the options for decommissioning and understand the resources required to carry this out. In order to offer clients the best possible all-round service with regards to this, BIS Inspection has announced a new strategic alliance with PDL Solutions (Europe) Ltd and Star Net Geomatics.

In particular, demand has been high for the preliminary decommissioning studies required when an asset is to be decommissioned. These help operators to understand the details of the asset and its conditions so they can look at the options for decommissioning and understand the resources required to carry this out. In order to offer clients the best possible all-round service with regards to this, BIS Inspection has announced a new strategic alliance with PDL Solutions (Europe) Ltd and Star Net Geomatics.

“The agreement will see BIS Inspection offer a fully integrated facts-based approach using the latest in high definition 3D laser scanning and true-to-view photographic technology. Combining this with fully integrated engineering solutions, clients will have access to a 3D database of facts about their asset, its current level of integrity and the decommissioning options available for it. This approach aims to provide clients with the best practicable means to decommissioning and optimal environmental options for each campaign.

“Equally, a facts-based approach takes away the uncertainty that often surrounds decommissioning, providing a clear range of options for the entire process, with the safest, most efficient and correct sequence in mind. Historically, many surveys were carried out using as-built diagrams, which can easily become outdated and obsolete during the lifespan of a platform, resulting in time consuming amendments and repeat surveys. By providing accurate dimensional information and 3D photographic walk through visualisations, we believe we are taking survey capabilities to the next level within the offshore market place. The specialist technology is already successfully deployed within the nuclear sector, and also has great potential in this offshore sector in offering market-leading solutions,” elaborates Nigel.

BIS Salamis is currently in the process of trialling the technology offshore, and will further develop its potential throughout the year. This forms an element of the company’s ambitious plans for unique technologies and specialist services, which in turn contribute to its clearly defined strategies to grow its inspection and integrity services. In achieving this though BIS Salamis’ greatest challenge is shared with the industry as a whole: “It is finding the right people to join us in delivering our capabilities and achieving our goals,” reveals Nigel. “This is the case throughout the oil and gas industry, and is predicted to continue for the foreseeable future. It is a particular challenge for us as we seek out the best people, with the right competencies, behaviours and attitudes. Our recruitment process is tailored to ensure that we are selecting the best and we have systems in place to ensure talent is retained and developed,” he concludes.

BIS Salamis

Services: Multi-disciplined service contractor