Calidus Engineering: Pioneering High-Temperature Downhole Solutions for Extreme Environments

Hot prospects

“We are not just another small borehole tool development company, we are extremely unique in what we can offer our clients, and how we operate,” says Nigel Halladay, managing director at Calidus Engineering.

The company, which is co-owned by Badger Explorer ASA and based in Cornwall, is one of the world’s leaders in the design, development and production of high reliability downhole systems, particularly suited for harsh environments and high temperatures. In conjunction with Badger, the business is currently working on a unique fly-by-wire drilling tool.

Nigel expands on the background of the business: “Calidus was established in 1999 to provide a complete range of services, solutions and development capabilities in the areas of precision  engineering, custom design and consultancy to the oil and gas market and other sectors. What really differentiates us is that a customer can come to us with a request for a tool development and we can carry out the R&D in areas including hydraulics, mechanics, electronics and software, followed by prototype manufacture and final production.”

engineering, custom design and consultancy to the oil and gas market and other sectors. What really differentiates us is that a customer can come to us with a request for a tool development and we can carry out the R&D in areas including hydraulics, mechanics, electronics and software, followed by prototype manufacture and final production.”

Calidus’ wealth of experience equates to more than 200 man-years in the design and development of very hostile environment downhole tool systems: “We are capable of building tools and systems for use in very high temperatures of up to 400 degrees Celsius,” says Nigel. “These include production tools. wire-logging tools, MWD systems, permanently deployed gauges, SMART well applications, and subsea control and power distribution systems.”

In November 2007 Badger Exploration ASA acquired a 50 per cent stake in Calidus, securing the company’s expertise for the development of its unique drilling system development. Badger was established in 2003 to design and develop the Badger Explorer – a completely autonomous formation and reservoir evaluation fly-by-wire drilling tool that drills into the ground without the need for a drilling rig. Rather, the Explorer drills into the seabed and buries itself using a slim, electrically powered system and continuously records data from a number of innovative sensors.

Developed through the use of proven technology and proprietary solutions, the Badger Explorer is a non-reusable exploration solution that will offer oil companies significant advantages over current technology. For example, the elimination of the need for a drilling rig will reduce the costs of exploration by up to 80 per cent, increasing the number of possible discoveries for a total exploration budget. Furthermore, it provides more comprehensive data collection and mapping of mature and new areas, and considerably shortens the time from discovery to development.

Nigel is understandably enthusiastic about Calidus’ collaboration with Badger Explorer: “The Badger team have a great deal of experience in the industry, and the investment in Calidus is helping to fuel much of our planned growth. The Explorer project is a unique, multi-million dollar project that will yield excellent results and opportunities when it finally comes to fruition.”

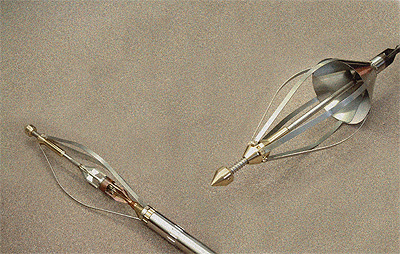

Together with Badger Explorer, Calidus works with many of the industry’s leading names to develop solutions tailored to specific client demands. Nigel elaborates: “One of our developments is our  Pro-log 350s, which is a geothermal specification (PLT) tool with a full 140MPa/20kpsi version for oil and gas applications.

Pro-log 350s, which is a geothermal specification (PLT) tool with a full 140MPa/20kpsi version for oil and gas applications.

“We are currently working on a 400 degrees Celsius rated version of this tool as part of the HITI Project, which is an EU funded operation involving six countries, working to develop instrument systems to support the Icelandic Deep Drilling Project (IDDP),” he continues. “We are the key company producing the very high temperature downhole hardware for the project, which will be memory based, but will also have a wireline surface read out (SRO) internal sub option for 300 degrees Celsius for lower temperature (wireline) uses. These kinds of projects perfectly illustrate out strengths – we can take a very wide range of problems or demands from individual customers, tackle them very effectively and produce working solutions that offer a number of benefits.”

In its first decade, Calidus has experienced considerable growth, and its reputation has flourished in the industry. Nigel believes that the changing face of exploration work – including the increase in operations in deeper waters and harsher environments – has benefited the business: “The oil reserves are getting deeper, hotter and harder to get at and as a result the instrumentation, and the demands on the instrumentation, are changing continuously. As these demands become increasingly severe, and the operational standards become more challenging, that is where our expertise and our experience can really come into play,” he says. “As this situation continues we are ideally placed to remain at the forefront of developments as we have the capabilities and skill to help companies improve the thermal performance and temperature capability of their devices.”

Looking to the future, Nigel explains that one of the key focal points for Calidus is to build on its success by further expanding its global presence: “I think that one of the fundamental challenges that we face is convincing prospective clients that our location is in no way a hindrance to their operations. We may not be based directly in Aberdeen or Houston, but we have continuously supported major projects for customers in locations around the world, including Japan, with no problems at all. We travel a lot to meet new and existing clients, and to spread our business on an expanding scale, and I think that our experience and quality allow us to do this successfully.”

Nigel is right to remain confident, with further expansion planned and the reputation of Calidus increasing daily, the business can look forward to a bright future: “We are certainly looking at growing and consolidating the operation. We currently have four operational premises, which we are looking to bring under one roof in the next 12 to 18 months. At the same time we are in the process of doubling our staff level and gaining new and exciting clients. I think that the successful completion of these plans, combined with the promising work we are doing with Badger, means that we are looking forward to a good future,” he concludes.

Calidus Engineering Ltd

Services: Downhole tool development