Cape Environmental Services Offshore

Flying high

Since its inception in 1893, Middlesex based Cape Plc has developed a global presence with well established and reputed subsidiaries trading in the UK, Europe, CIS, North Africa, Qatar, Australia, Saudi Arabia, UAE, the Philippines, Singapore and Thailand.

With its 18,000 competent and trained personnel operating across the globe, Cape Plc offers safe, reliable and intelligent solutions both on and offshore. Split into seven sectors, oil and gas onshore, oil and gas offshore, power generation, minerals and mining, chemical, steel, marine and other, the highly successful group trades on the main market of the London Stock Exchange and reported  adjusted revenues of £697.1 million in the financial year ending 31st December 2013.

adjusted revenues of £697.1 million in the financial year ending 31st December 2013.

As part of Cape Plc, Cape Environmental Services (Cape ES) is a leading provider of onshore and offshore cleaning and decontamination services, having delivered pioneering solutions to its blue-chip client base within the oil and gas, heavy industry, petrochemical, manufacturing and pharmaceutical industries for four decades. A proud integrator of a broad range of innovative, environmentally friendly, industrial cleaning techniques since 1969, the company complements its high pressure water jetting, high airflow vacuum services and chemical decontamination processes with waste management services and on-site waste handling capabilities; in addition, the company offers infrastructure monitoring and refurbishment.

Previously known as Cape DBI, Lovat MacGregor, business development manager of Cape ES states the company was rebranded in 2012 to strengthen its global appeal and ensure instant recognition across the markets it operates in: “The change was twofold, firstly to identify Cape ES as an environmentally sound contractor in heavy industrial cleaning and waste management, and secondly to distinguish between Cape Plc’s traditional core industrial services of scaffolding, insulation, asbestos removal and painting.”

As an independently trading division of Cape ES, itself a subsidiary of Cape Plc, Cape Environmental Services Offshore (Cape ESO) works in close partnership with clients such as Shell UK Limited, BP, Total, Apache NS, Maersk Oil, Nexan Inc and Daewoo Energy on innovative industrial cleaning and decontamination services for process pipework, tanks and vessels. To ensure ongoing success, the company is a staunch supporter of utilising the most state-of-the-art technology and providing regular training to its highly qualified and skilled personnel, which results in time and cost efficient solutions that reduce downtime and boost overall production time. “Highly respected for its innovative solutions and exceptional safety and quality standards, Cape ESO has built an unrivalled reputation for its total integrated package delivery,” says Lovat. “We are viewed throughout the industry as a pioneer in safe, environmentally sound industrial cleaning techniques, with our full suite of technical solutions a key differentiator against our competitors. We also provide a one-stop-shop service to clients and facilitate customer shift to fewer, better resourced suppliers deploying best practice in addition to focusing on minimising downtime and total job cost reduction.”

An example of the company’s commitment to innovation is its award winning Syphonvac system, which facilitates the online removal of sand from production vessels without needing to shutdown production or for confined space entry to the vessel by personnel. So far it has been operated without interruption on 14 platforms and 35 projects, notes Lovat: “Cape ESO has deployed Syphonvac  for several leading international operators including BP, Shell UK E&P, Hess Ltd, Maersk Oil and Nexen Inc. BP engaged CES to install and operate the Syphonvac system to the LP Separator on the ETAP platform in the Eastern Trough Area of the UKCS North Sea. The ETAP has a crude oil production of 40,000 bopd. Cape ESO removed almost three tonnes of sand throughout the process, with the vessel remaining in full production for the duration of the procedure. Time saving achieved by this procedure was approximately 17 days in the turnaround period.”

for several leading international operators including BP, Shell UK E&P, Hess Ltd, Maersk Oil and Nexen Inc. BP engaged CES to install and operate the Syphonvac system to the LP Separator on the ETAP platform in the Eastern Trough Area of the UKCS North Sea. The ETAP has a crude oil production of 40,000 bopd. Cape ESO removed almost three tonnes of sand throughout the process, with the vessel remaining in full production for the duration of the procedure. Time saving achieved by this procedure was approximately 17 days in the turnaround period.”

Setup of the Syphonvac is generally possible within 12 hours, compared to a seven to ten day full vessel shutdown preparation period to facilitate confined-space entry directly by personnel. The system is fully certified to ATEX standard, and is compact to allow for deployment in any global region, making it capable of export to the full international oil and gas exploration and production marketplace.

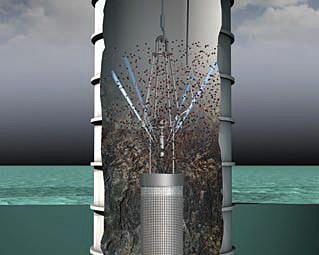

Fully committed to research and development, the company also recently worked in conjunction with Apache North Sea to create the new ‘Torpedo’ unit – an environmentally safe internal overboard caisson cleaning system that can operate below sea level to remove scale and marine growth from the caisson back to the platform deck where the debris can be disposed of. “From our experiences using the Torpedo system to capture debris we have collected between 0.5 – 1.0 tonne of scale and marine growth during each internal caisson clean. This is material which pre the Torpedo innovation would have fallen to the seabed. By working in partnership with Apache North Sea, we have developed a safe, innovative and environmentally compatible system for undertaking caisson cleaning projects of any nature,” says Lovat. The Torpedo system awarded a Commendation Award for Innovation by the EIC (Energy Industry Council) in October 2014.

With ongoing long-term contracts with BP, Shell UK Limited and WGPSN in the cold cutting segment of the business alone, the future looks positive for Cape Environmental Services despite market challenges, as Lovat concludes: “The next 12 months will be demanding as operators will look to cut costs, gain added value and strive to reduce/eliminate periods of production downtime. We will use our experience, reputation and innovative technology to focus on realising these operational targets for our clients and prospective clients.”

Cape Environmental Services Offshore

Services: Industrial cleaning, decontamination, non-intrusive tank and vessel cleaning