CAPE Holland: Innovators in Offshore Piling Solutions

Good vibrations

CAPE Holland was founded in 2002 by a father and son team set on extending the family links within the piling sector, which began in the 18th century.

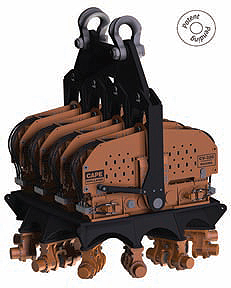

Managing director Laurens de Neef provides an insight into the activities of the group as it grows within its market position: “Although starting as an international piling equipment trading company, we soon started engineering and constructing special equipment for the piling industry. With a large fleet of hydraulic impact and vibro hammers for sale and for rent, our involvement in the offshore market deepened. Our breakthrough success offshore was the development of a multiple linked vibro hammer for the Riffgat Offshore Wind Farm project in 2012, driving 30 monopiles of 750 tonnes, fast and silently into the German North Sea floor.”

To be able to satisfy the demands of the market the business not only designed its range of vibro hammers in-house, but it also manufactures the technology, specifically for the offshore market. Recognising its strengths, in October 2014 it was announced that FoundOcean Group had acquired a majority stake in the CAPE Holland Group. Commenting on the arrangement Laurens points out: “FoundOcean has a wealth of experience in the offshore market and over the past 50 years has built a global sales network. The strategic move to join such a strong organisation is key in our efforts to achieving future growth, and offering both services as a package can be a great benefit to the customer.”

Whilst the development and manufacture of vibro hammers, power units and hose reels has promoted its position at the leading edge of the offshore industry, Laurens adds: “We offer operational assistance for our own equipment, and piling equipment from others and our in-house engineering department is strong in coming up with project specific solutions. Within the oil and gas industry our equipment is frequently used for installing pin and skirt piles for jackets and other substructures, but also for various types of anchor piles such as FSOs.” Other applications include the installation of starter piles for pipelines, where the ability to extract piles is particularly important. Extraction methods are also increasingly valuable for decommissioning projects, where old piles can be removed completely.

Vibro technology has proved itself a great contributor in the reduction in the cost of installation and environmental impact within the offshore wind sector, but with a broad spectrum of clients, its benefits go much further. “We expect significant growth in the use of vibro hammers across the oil and gas industry. The technology can be used as an upending/handling tool, which will significantly reduce handling and installation time, reduce the amount of additional equipment required and improve safety,” says Laurens.

Not only did the Riffgat project demonstrate the benefits of a vibro hammer for installing very large piles offshore, but critically it was the trigger for the main offshore renewable utility companies to pay close attention, as Laurens points out: “This resulted in further test projects, including the current large scale joint industry test at Cuxhaven to verify the lateral resistance and certify installation by vibro hammer. The outcome of this test, expected early 2015, is likely to change how piles will be installed in the future.

“Our latest developments have resulted in the CAPE Vibro System™, which can be configured with an upending option. The system is able to pick up a stored pile, upend it to a vertical position, lift it to the correct position and drive it down, whilst correcting verticality while driving if necessary, in one single handling operation without the need of a gripper or seabed installation frame, saving valuable time.” Subsea operations in up to 100m water depths are possible with few alterations and deeper operation is possible with an air compensation system. With the choice of configurations and pile clamps, this system can be deployed for almost any pile diameter including XXL monopiles.

“With the renewable sector having gone through a quiet period due to political uncertainties it has now stabilised and an increased number of projects have been given the green light. The vibro hammers will make a big contribution to reducing noise compared to the noise created by traditional installation methods. As the industry is slowly changing and focusing on the logistics, our CAPE Vibro System is able to shorten the critical path and allow a safer operation. Oil and gas contractors really benefit from the upend vibro as a combined handling and installation tool. The vibro hammer can get the piles from their storage frame to a stable position, eliminating the risks of the jacket or template falling over. In parts of the world where very weak soil layers are present, the technology is often chosen by contractors to eliminate the risk of pile run,” explains Laurens.

Growth for CAPE Holland is inevitable as it satisfies the expected increase in demand from both the renewables and the oil and gas market, as Laurens concludes: “We strongly believe there are substantial efficiency improvements to be made in the installation process of foundations and other piling solutions, and particularly in the logistics of a project.”

CAPE Holland

Services: Construction and piling equipment