Castle Metals UK Ltd

Crowning achievement

Combining the specialist capabilities of four individual businesses under a strong international parent, Castle Metals UK is the new integrated venture from leading US company A.M. Castle.

The Metals UK Group, as it was known previously, was first brought together in 2003, when high performance alloy specialists Metals UK acquired E Harding & Sons, KKS Stainless, and Loks Plasma Services. Each with their own rich heritage in the market, which in the case of E Harding dates back to 1884, the combined expertise of these four companiesenabled Metals UK to offer multiple processes to the metal alloy market. In 2008 the Metals UK Group was acquired by A.M. Castle, and is currently undergoing a rebranding in line with its new identity as Castle Metals UK.

Commenting on this major development in the company’s structure, Robert Whitehouse, general manager of Castle Metals UK, says: “At present we have four faces to market, but with this new rebranding these will be consolidated into one globally known name. Over the last six months we have implemented various marketing strategies in preparation for the official Castle Metals UK launch later this year. Being part of a major corporation like A.M. Castle provides us with greater financial stability, which gives us the security to support customers on long-term projects. Another advantage is greater global buying power, and access to much larger material stocks than we can specifically hold ourselves.”

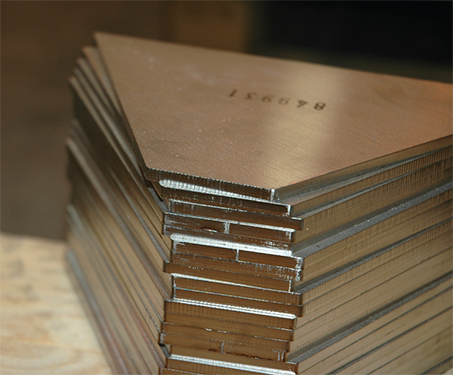

As suppliers of a wide range of speciality alloys such as nickel, duplex and super duplex, and stainless steel alloys, this provision from stock service is one aspect Castle Metals UK prides itself on, alongside its in-house added value processing capabilities. Using these processes, which include laser cutting, water jet cutting, band saw, plasma and high definition plasma, and bevelling, Castle Metals UK is able to cut these alloy materials to any size required. In line with its projected sales strategy for 2011, the company invested £1 million in new machinery in late 2010.

“Our new laser machine was installed in February and is now fully operational, and this is being followed by the installation of a new water jet machine in late March,” describes Robert. “Our existing machines are remaining operational, but this investment gives us improved capabilities and an increase in capacity. Given that our customer base is expanding, this is important in order to ensure that we provide the same high-levels of quality to all clients. We have also seen a sharp increase in nickel prices, and extension of lead times from the steel mills this year, so we have also invested in our inventory to compensate for this.”

“Our new laser machine was installed in February and is now fully operational, and this is being followed by the installation of a new water jet machine in late March,” describes Robert. “Our existing machines are remaining operational, but this investment gives us improved capabilities and an increase in capacity. Given that our customer base is expanding, this is important in order to ensure that we provide the same high-levels of quality to all clients. We have also seen a sharp increase in nickel prices, and extension of lead times from the steel mills this year, so we have also invested in our inventory to compensate for this.”

Beyond the usual demands of quality and durability, the harsh operating environments of the oil and gas industry also dictate some more specific requirements in terms of the type of materials used. “Clients in the oil and gas industry are often looking for a specific material for a specific application in their operations, which we work to fulfil. In addition, many only want materials that meet the NORSOK standards as developed by the Norwegian petroleum industry. Unlike many of our competitors, who only gain this certification after the order comes in, we stock NORSOK-accredited material from the beginning, which reduces lead-time delays. We work very closely with the steel mills, and our customers, to ensure that we are offering materials that meet any new grades and specifications as they are released,” explains Robert.

Oil and gas is just one of several industries that Castle Metals UK is active within, where not only is safety critical, but also the products are often used in extremes of environments in terms of temperature or corrosive properties. One such growing market for Castle Metals UK is the nuclear sector with the company currently taking part in the EVAP D project, one of the largest UK nuclear projects, at Sellafield on a £1.5 million contract. Given the speculated increase in activities within the UK nuclear market in the coming years, Castle Metals UK is working to align its services with this sector through the employment of key nuclear business development personnel, and investment into non-contamination facilities.

In terms of the wider international market, Castle Metals UK is dedicated to fulfilling the needs of speciality metal customers worldwide, with export activities in 49 countries across the globe. This is aided by the company’s multi-lingual staff and understanding of individual markets, as well as vigilant approach to export controls and compliancy. Having been awarded the Queens Award for Enterprise in International Trade in 2009 in recognition of its commitment to the export market, Castle Metals UK is continuing to focus on growing this aspect in the future. “Obviously a key focus for the next few years is the integration of Castle Metals UK and that rebranding into the market, where as part of A.M. Castles we are positioned as a global market leader in the supply of speciality metals. Beyond this we intend to expand further into Europe and East Asia, as well as other areas, which will be facilitated by our parent company A.M. Castles’ established presence in these markets,” concludes Robert.

Castle Metals UK Ltd

Products: Specialist and stainless steel alloys