Demaco: Leading Cryogenics Innovation and Liquid Hydrogen Ventures

Ice-cool construction

As it continues to lend its cryogenics expertise to groundbreaking research projects across the world, Demaco Holland B.V. is exploring an exciting new avenue in the shape of liquid hydrogen

“Strange and turbulent” is how Niels Beers, CEO of Demaco Holland B.V. (Demaco), describes the two years since Covid-19 first made its presence felt across the globe. An expert in the field of cryogenics, and a builder of infrastructure for producers of industrial gases and liquid gas end-users, Demaco was well-prepared to withstand the initial disruption, bolstered by its exceptional performance in 2019. As a halt on international travel saw flights cancelled, the company was even able to cut costs, making 2020 its best ever year for profitability.

Unfortunately, the same couldn’t be said for Demaco’s intake of new orders. “There were far fewer smaller projects compared to a normal year,” Niels confirms. “Typically, our customers might be gas companies who provide services to the food, medical and pharmaceutical sectors. During Covid-19, everybody was waiting to see what would happen with the economy, so investments were postponed.”

It wasn’t a complete standstill, however. As an integral facilitator for a large number of industries, Demaco enjoyed essential status throughout the pandemic. Yet, trading conditions in 2020 were far from ideal. “Particularly at the beginning, it was very difficult,” Niels recalls. “The biggest problem, especially for sales, was that we couldn’t go to our customers. Instead, we had to start video-calling. Ironically, that’s become one of the biggest advantages of the post-pandemic age. Pre-Covid-19, we’d often fly to a city like Madrid for an hour-long meeting, and then fly straight back. That’s ridiculous. By communicating virtually, we’re now able to save a lot of costs, and a lot of time.”

That time is being put to good use. Throughout the last year, Demaco has continued to innovate in its contribution to the cryogenics industry. “We look at innovation from a number of angles,” Niels says. “We’re continuously working on the further development of our own cryogenic components, keeping an eye on the current technology in the market to do so. We’re also developing our processes, searching for new welding methods, and we’re currently considering a new way of cutting pipes to increase our efficiency. In 2021, our biggest development was the launch of our configure-to-order software program, through which we can automatically determine the price of any combination of project components, and generate a quotation to be sent to our customers.”

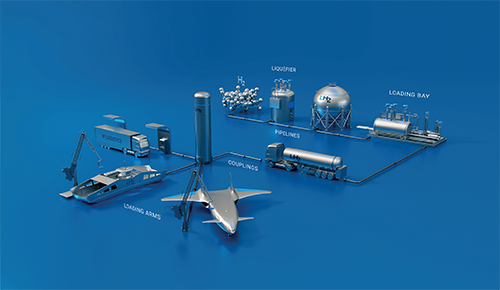

In June 2021, Demaco announced its entry into a new market of opportunity: liquid hydrogen. “At temperatures of -253 degrees Celsius, liquid hydrogen is very cold,” Niels notes. “At Demaco, cold is what we’re good at, and we’ve been involved in the research, prototyping and delivery of advanced liquid hydrogen projects for more than three decades. The production of hydrogen is costly, but if you have the capability to do so in a country where there’s plenty of wind and sun – the Middle East or Australia, for instance – then it can be profitable. We’re able to create the necessary vacuum-insulated infrastructure to transport or condition that hydrogen as a liquid, to prevent it reverting to gas, and ensuring that you don’t therefore lose all the energy that you’ve put into it.

“Since the announcement was made, we’ve already had success, with several projects sold to gas companies and end-users,” Niels continues. “We’ve also been commissioned for the design and manufacture of a set of 12 hydrogen truck loading stations in South Korea, in order to facilitate the country’s rapidly expanding hydrogen-electric market.”

Another highlight amid this work is Demaco’s ongoing contribution to the European Spallation Source (ESS), a neutron particle accelerator currently under construction on the outskirts of Lund, Sweden. “We’ve been commissioned to supply the cryogenic infrastructure for the transport of liquid hydrogen, used to cool down the neutrons within the accelerator,” Niels outlines. “We’re currently in the process of that installation, which consists of piping and a valve box. Similarly, we’re also involved in the FAIR-GSI accelerator facility currently under construction in Darmstadt, Germany, where we’re providing the infrastructure to supply liquid helium to the magnets.”

Such unique technology demands a specialized process of manufacture. “We prepare and clean the pipe, before carrying out the welding and insulation,” Niels explains. “A vacuum has an insulating function of its own, but we also insulate the pipe with multiple-layer insulation to reflect radiation on a long-term basis. We then assemble the line or the weld box, before initiating the vacuum procedure. Once complete, we clean the product exterior in advance of transportation. In 2021, we decided to expand our production facility by an additional 1200-square-metres, because we were in danger of outgrowing our premises. The new extension will provide a dedicated area for preparation, allowing us to create more welding spots in our existing factory.”

Such unique technology demands a specialized process of manufacture. “We prepare and clean the pipe, before carrying out the welding and insulation,” Niels explains. “A vacuum has an insulating function of its own, but we also insulate the pipe with multiple-layer insulation to reflect radiation on a long-term basis. We then assemble the line or the weld box, before initiating the vacuum procedure. Once complete, we clean the product exterior in advance of transportation. In 2021, we decided to expand our production facility by an additional 1200-square-metres, because we were in danger of outgrowing our premises. The new extension will provide a dedicated area for preparation, allowing us to create more welding spots in our existing factory.”

As Niels points out, nothing would be possible without the efforts of the company’s highly trained staff. “The people at Demaco are our capital,” he says. “We’re very capable both practically and theoretically, and we’re a healthy mix of men and women, young and old, of more than 25 different nationalities. The market in which we operate is a very interesting one for our employees, and the fact that almost all of our work is exported is exciting for the measurement, consultation and installation staff, all of whom get the opportunity to travel regularly. Our culture, too, is very important. We’re a flat organization; everyone knows each other, and together we have a lot of fun.

“In 2022, we’ll continue to operate in a series of diverse and stable markets,” Niels concludes. “Hydrogen is an important pillar, and will become an increasingly vital part of our turnover. Equally, the research world is not standing still. There are a lot of particle accelerators across the globe, for which cryogenics are essential. CERN in Geneva is refurbishing its accelerator, and within two months we expect to receive a quotation request for a very large project. In the US, we’re already involved in the Deep Underground Neutrino Experiment (DUNE). They’re currently prototyping the catching of particles in a large argon bath. If that’s positive, they’ll enroll the whole project, which would be enormous.”

Demaco Holland B.V.

www.demaco-cryogenics.com

Services: Cryogenic infrastructure development