Drass Tecnologie Sottomarine: Leading Deep Diving Innovation Since 1927

Going deeper

Drass Tecnologie Sottomarine’s history has very much been in step with that of diving, particularly with regards to the introduction of personal diving equipment.

In 1937 the company held the world record for the atmospheric diving suit, and has since been continuously operating within the diving, medical, and military sectors.

“Following the resurgence of the saturation diving industry in 2004, Drass has built more than half of the certified saturation diving systems in the world. We developed a new approach to the diving system manufacturing process, and applied it to in-built, modular, and surface diving systems,” begins marketing manager Claudia Ramirez.

“In the past, diving systems were always built to client specifications, which resulted in many different systems. Thanks to the co-operation and understanding of our clients we have been able to deliver the advantages of systems built on identical models, each supported by sound engineering and complete technical information. As such we have created a complete standardised engineering package covering the design, manufacturing, installation, and life support of the in-built saturation diving, surface diving, and modular systems. This means we are now able to provide fully interchangeable built-in systems for ships, dramatically increasing the competitiveness of our solutions,” she continues.

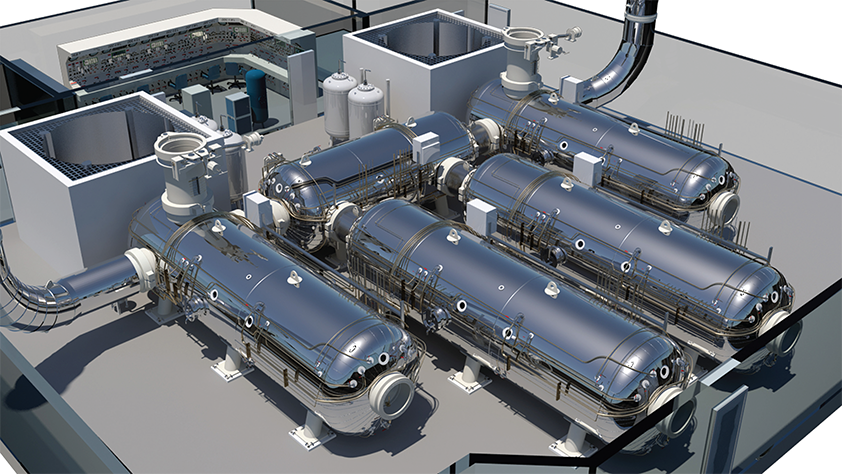

Within this portfolio there are a number of products of particular interest including the 100 Series dive system, 700 Series surface diving system, and 900 Series modular saturation system. Since 2006 Drass has delivered the 100 Series saturation diving system to market leading vessels such as the Bibby Sapphire, Toisa Pegasus, Well Enhancer, Harkand Iremis, and Harkand Da Vinci. The company is also completing new builds for SBM and Halul, and recently began a project with Subsea7. “This is our most important project at present, not only because it has allowed us to operate with probably the most prestigious diving company, but also because it lets us perfect the 100 Series through the precious operational feedback received from Subsea7,” notes Claudia.

This type of relationship is one advocated by Drass as it enables the company to take the feedback from the field and feed it into a continuous improvement cycle. In much the same way, one of the main targets of Drass is to increase its R&D scope, whilst remaining cost effective. This includes modernising designs with the introduction of state-of-the-art concepts, and extending the range of equipment on offer.

“Our R&D division has been very busy,” confirms Claudia. “Our special flame sensor for example, is something we have created to increase the level of safety for personnel in hyperbaric operations. There is also a transfer of technical solutions and developments from the defence business, to the commercial diving sector and vice versa. The use of gas chromatography for commercial diving applications is one example, and the possibility to use approved touch screen monitors in the hyperbaric chambers as entertainment and conference systems is another significant achievement we have introduced.”

“Our R&D division has been very busy,” confirms Claudia. “Our special flame sensor for example, is something we have created to increase the level of safety for personnel in hyperbaric operations. There is also a transfer of technical solutions and developments from the defence business, to the commercial diving sector and vice versa. The use of gas chromatography for commercial diving applications is one example, and the possibility to use approved touch screen monitors in the hyperbaric chambers as entertainment and conference systems is another significant achievement we have introduced.”

The newest innovation though is the Drass i100 automation system, which is incorporated into the Drass 100 Series diving solution. “The aim of the i100 is to integrate the control of all units of a standard Drass saturation diving system making it easier to manage, and providing log functions for main operations, alarms and faults,” explains Claudia.

She continues: “The i100 has been designed to maintain the automation structure as simply as possible, rely on standard and proven hardware and software, and avoid over-engineering of the system. It also uses a modular system in order to reduce the risks associated with the validation of software and hardware between in-house modules, and as a standard solution is applicable to the entire fleet of 100 Series systems.”

The perceived need in the market for reliable and high performance diving systems has been a real opportunity for Drass to grow rapidly, whilst consolidating its success. “The market is extremely buoyant at the moment, and Drass is definitely going to play a major role thanks to the technological improvements we have introduced in our solutions,” enthuses Claudia. “Drass is able to promptly answer the increasingly demanding needs of offshore players who are no longer satisfied with the traditional prototyping philosophy of the past diving manufacturing industry.

“Our flexible manufacturing process, based on standard and pre-approved equipment, allows us to satisfy multiple requirements. The capability to design and build in-house, together with a proven and unrivalled reference list, gives us competitive prices and short delivery times – strengths that are paramount for the present needs of the market and will contribute to our future success,” she adds.

As a company that has long been at the forefront of its market though, Drass’ plans for the future are not only focused on consolidation. Demands for the application of new technologies to diving systems from the market means that innovation is high on the agenda. This is not only in terms of the software or hardware itself, but also in being able to meet the levels of reliability and simplicity needed for that operational environment, at an acceptable cost level.

“At the same time we are developing our ‘systems in operation’ division with the aim of supporting the complete life cycle of the 100 Series, including training and competence upkeep. The automation division shall continue to develop reliable safety and operational software to improve the performance of the technology supporting the 100 Series. Finally a new E-commerce system will be introduced in the market to make it easier for our clients to access spares and components, including personal diver equipment,” concludes Claudia.

Drass Tecnologie Sottomarine

Products: Deep diving equipment