Duco

Anticipating growth

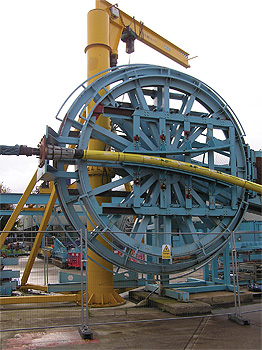

Part of the Technip Group, Duco has designed, manufactured and supplied subsea umbilicals for the oil and gas industry for over 30 years.

Today, Duco markets a comprehensive range of bespoke umbilical systems, subsea products and offshore services, which are supported by a network of sales, engineering, project management and manufacturing expertise. Delivering these services are more than 600 employees located in dedicated facilities, in Newcastle, Houston and Angoflex.

The Technip Group, to which Duco belongs, provides all or part of the services involved in basic and detail engineering, procurement, construction and project management, and has a long track record in implementing large turnkey contracts. In particular, in the subsea segment, Technip is in a good position to fulfil the expectations of operators wanting to entrust the largest possible range of services to a single contractor that can effectively manage all the aspects of a major field development.

Jean Louis Rostaing, managing director of Duco, describes how belonging to the Technip Group has real benefits for Duco: “Being part of this large and industrious group means that we have a strong backing not only in terms of financial support, but also project management and engineering services. The expertise and skills of the Technip Group are a huge benefit to Duco and enhance the products and services we provide.

Duco has been developing pioneering umbilical designs ever since subsea production systems were first installed in the 1970s. At the beginning of the 1990s, the systems became an accepted means of offshore hydrocarbon recovery, and Duco’s business expanded. Early systems generally involved short tieback distances installed in water depths accessible to divers, which are typically less than 200 metres, and used umbilicals constructed almost entirely from thermoplastic hose fluid conduits. Duco’s experience of thermoplastic umbilical supply is showcased in some of its previous projects, which contain Duco manufactured hose.

Steel tube conduits were gradually introduced in the mid-1990s, and their use has escalated in recent years due to increased tieback distances and the exploration of deeper water depths. As such, Duco has been supplying steel tube umbilicals to the industry since 1994, and introduced the first steel tube umbilical to the Gulf of Mexico region in 1995. In some cases, combinations of steel tubes and thermoplastic hoses are employed in umbilicals. This concept, pioneered by Duco in the late 1990s, provides the subsea system designer with greater flexibility in optimising the performance of the subsea production system.

Jean-Louis elaborates on the strengths of the company’s current umbilicals range: “Combining our long experience in manufacturing umbilicals with the capacity to produce a full range of products, we have a service that is unique as most of our competitors offer a much smaller choice of umbilicals. We have spent a lot of time pioneering new technology and we’ve succeeded in developing better umbilicals as a result. In one project, the Total K5F project in the Dutch sector of the North Sea, which we carried out earlier this year, was the first instance in which we supplied the umbilicals to service the first all electric subsea tree.”

The K5F project involved the first umbilical of its kind, providing electrical power to operate actuators on the subsea tree. “This was the first time such an umbilical had been developed because traditionally it uses hydraulic control,” explains Jean-Louis. “The 18km umbilical was installed on the subsea tree earlier this year, and I think it has been a good opportunity for us to demonstrate our engineering capabilities. Additionally, our project management expertise enables us to realise the interface between the host facility and the subsea tree.”

All the R&D work behind Duco’s innovative systems is carried out at its facility in Newcastle, where it operates a large R&D centre, employing around 60 engineers and technicians, and with a budget of about three million USD per year. Jean-Louis elaborates: “In this last year, we have been developing and extending the capabilities of our umbilical systems to be able to produce a better product that can work in high pressure applications. Moving forwards we will focus mainly on electrical cables as we see their use increasing within umbilicals for the offshore oil and gas sector.”

He goes on to explain how important QHS&E is to the business: “Safety is a strong value for the Technip Group and Duco. We want to be a reference in the industry in terms of safety and environment. Quality is also very important to us as it’s our major focus, and we have all the certification needed to demonstrate the quality we maintain across the design and manufacturing process. All along the supply chain we have a large number of requirements in terms of quality. We always look for suppliers with very stringent qualification programmes for their materials and processes.”

Despite recent successes, the recession has caused some set backs for Duco, as Jean-Louis explains: “We have certainly been hit by the crisis. In early 2009, we were experiencing a downturn, but now we can see some signs that the industry is beginning to grow again. Duco has had some successes recently, in terms of tendering and we have won some new projects. As we see a number of delayed projects being resumed, we have great expectations for 2010. Our focus, as we move the business forwards, will be on the ultra-deepwater sectors as we expect to see a lot of development in this area.”

Finally he outlines where the company will focus its growth in the coming years: “In terms of a strategy for the growing market we are looking at Angola, we have a plant there and we can extend its capacity to supply the full range of products required by our clients. We are also positioning ourselves in Malaysia to enter the Asia Pacific, Middle Eastern and Indian markets, which are all growth areas. We can see some major projects and important growth here.

“Currently Duco is a major leader in its market and we want to be well-known in terms of quality, safety and environmental protection. In line with our aim of being the most reliable provider of umbilicals and solutions for our clients, we will continue our efforts on R&D operations and will keep a strong focus on our people to develop our business and maintain close relationships with our clients.”

Duco

Products:Subsea umbilical systems