Efficient Tank Farm Foundations with Keller’s CMM® Columns

Ground improvement with Keller’s CMM® Columns with Mixed Moduli offers an efficient alternative to pile foundations.

Within the framework of the expansion of GPS Group’s tank farm at Amsterdam Westpoort (GPSA), and working under a contract with Chemie-Tech LLC, Sharjah/VAE (www.chemietech.com) in Autumn 2018, Keller provided ground improvement services using its CMM® Columns with Mixed Moduli for the foundation of six new storage tanks, measuring 28 m and 36 m in diameter, and 25 m in height. This method is tried and tested worldwide as a customised, efficient and reliable solution for tank farm foundations in challenging, soft soils, and is particularly suited for soil improvement under large-area foundation slabs. The CMM® technology offers significant time and cost savings compared to conventional deep foundations using driven piles.

Multiple benefits combined in a single product

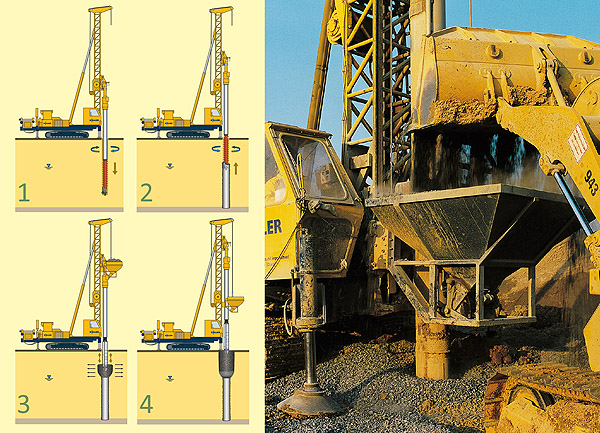

CMM® Columns with Mixed Moduli are hybrid columns combining the benefits of vibro replacement stone columns and rigid inclusions displacement columns in a single product. Rigid columns are produced first and improve and homogenize the deep soil. Subsequent vibro replacement using a depth vibrator ensures uniform distribution of loads over a large area.

Björn Böhle, manager of the Special Projects division at Keller, explains: “Even in the case of very weak soil and average to high area loading, this combination of technologies in a CMM® significantly reduces stress and load concentrations within the foundation slabs, which might otherwise occur in the case of supporting elements providing point-type contact. Slabs can be designed as elastically bedded elements, which offers substantial financial advantages. Further cost savings result from the fact that bending moments occurring in the foundation slab are relatively low, thus eliminating the need for costly substructures for load distribution. The amount of reinforcement steel and the thickness of the base slab can be reduced, and in some cases,  reinforcement may be entirely superfluous.”

reinforcement may be entirely superfluous.”

Further benefits of the CMM® Columns with Mixed Moduli Technology listed by Böhle are the extraordinary high speed with which CMM® can be introduced into the ground – the construction of one meter takes only half the time it takes to drive prefabricated piles into the ground – along with the elimination of the trimming work required for cast-in-situ piles, and the fact that the construction of CMM® involves the use of a full-displacement technology with no or only very little soil needing to be handled. “The significant reduction of the amount of drilling material compared to other methods of foundation construction not only reduces the amount of labour involved,” continues Böhle, “but also relieves the customer of the problems that may be associated with the environmentally compatible disposal of these materials.”

Construction of foundations completed in less than three months

To evaluate the efficiency of the technology, Chemie-Tech looked at several similar projects involving ground improvement for the construction of tank farms completed by Keller since the early 2000s. Böhle adds: “Apart from the time and cost savings resulting from the use of the CMM® method, our worldwide track record and the confidence our customers have placed in us based on the projects executed in the past, were the decisive factors for the customer to award the order – the first of its kind in the Netherlands. In fact, more and more customers are coming to realise that the reduction in follow-up and lifetime cost more than makes up for the higher initial outlay in the long run.”

Following placement of the order, Keller started the design and planning, using its Plaxis 2D and 3D FEM software specially developed for geotechnical analysis. The software enables experienced engineers to create a design which is optimised with a view to soil properties and statics within a minimum of time. Assumptions made for the design were subsequently validated on site by performing static axial load tests. Execution of the ground improvement work at Amsterdam Westpoort started in September 2018 and was completed as early as November in the same year.

An experienced and versatile specialist renowned worldwide

Bertrand Stoehr, Senior Key Account Manager and Major Projects Manager at Keller, states: “When it comes to selecting a site for a tank storage facility, considerations of structural engineering or suitability of ground often have to take second place to logistics or productivity criteria. This results in a wealth of new geotechnical challenges in connection with the construction of foundations for bulk liquid storage facilities, ranging from limiting settlement to ensuring adequate structural stability of tanks under a variety of static and dynamic loads, up to and including the avoiding of soil liquefaction.

“With decades of experience in design rating and soil mechanics, Keller is an internationally renowned all-round partner for such challenging geotechnical problems,” concludes Stoehr. “The example of the expansion of the Amsterdam tank farm shows how our ground improvement, pile foundation and grouting technologies, some of which were developed by Keller in-house, provide an efficient solution for virtually any task, even under the most adverse conditions.”