Enhancing Offshore Safety: Ramnäs Bruk’s Mooring System Solutions

The strongest link

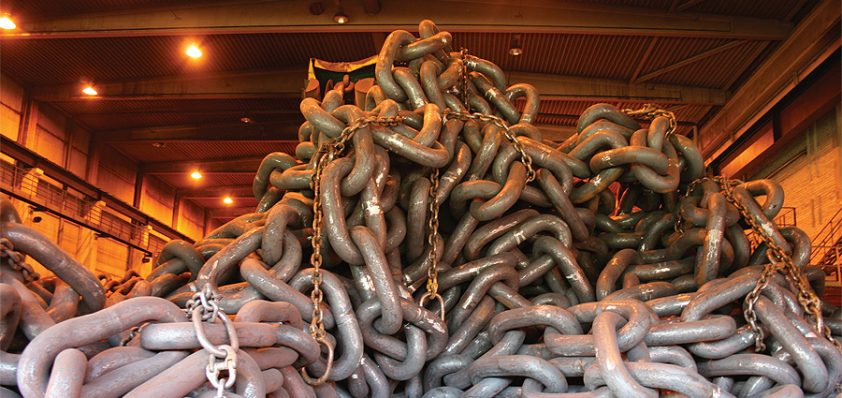

Sweden-based Ramnäs Bruk develops, manufactures and markets anchor chains, Ramfor and Kenter connectors, and accessories for qualified mooring systems, predominantly for the offshore industry.

Although established over 400 years ago in 1590, Ramnäs Bruk began forging stud link anchor chains in 1876 and has since grown to establish itself as a first choice for customers who prioritise quality at all stages of an operation. As of June 2008, Ramnäs Bruk has been 70 per cent owned by a Norwegian consortium led by Carl Arnet, one of the world’s chief specialists in offshore anchoring. The previous Swedish majority owners have the remaining 30 per cent shares.

The company is known worldwide for its dedication to quality and professional excellence. As an approved manufacturer by all major classification societies for both offshore grades and ship grades, Ramnäs Bruk produces long continuous lengths of high quality offshore mooring chains, with or without studs, in heavyduty materials. Throughout the years it has had a pioneering input on the development of chain and connector designs, as well as on the introduction of new manufacturing, inspection and testing routines. New connector designs, Ramfor and Ramfor slim, were introduced in 1990 and a new stud chain design, with an asymmetric stud in combination with controlled stud expansion, was introduced in 1991.

Magnus Westher, managing director at Ramnäs Bruk, comments on what sets the company apart from the competition in the marketplace: “Our strengths are our products and our ability to deliver them both correctly and on time. We also have our five-year quality warranty, which has been available for some time.” Quality is of upmost importance amongst Ramnäs Bruk’s staff, who understand the significance of supplying high standard products.

The company’s five-year quality warranty applies to all of its chains and was introduced as a method of ensuring long lasting product quality. Ramnäs Bruk’s responsibility during this warranty time, and according to Orgalime S 2000, is to solve any fault that may occur as soon as possible after a complaint is received, by repairing or replacing the product.

The company has recently installed a new state-of-the-art proof-loading machine in its factory, Magnus elaborates: “Of late we have been experiencing a lot of requests from customers with components that need to be proof loaded or break load tested on their behalf, and so we installed one more proofloading machine for that purpose. Customer demand is increasing as safety requirements are becoming ever stricter within the offshore business hence more equipment requires proof loading in this way, and so we invested in a machine that is used solely for this type of service. Previously the process was something that we carried out between the production of chains, but now we will give this service time and attention with a machine that addresses these specific requirements.”

In January 2009, Ramnäs Bruk received an order from Hyundai Heavy Industries shipyard in Ulsan, Korea. Magnus comments: “The end user for the project will be French oil company Total, with delivery starting in 2009 and continuing until mid-2010.” The order is the company’s largest to date, includes 142mm and 147mm chain dimensions and is intended for a floating production storage and offloading vessel (FPSO), which will be located in the USAN field just outside Nigeria’s coast. With an order value of over 120 MSEK, Ramnäs Bruk’s immediate future is secured amidst challenging financial times.

He continues, discussing the current condition of the industry: “The total demand in 2009 looks much less than it did in 2008 and there are several projects on hold that were expected to be up and running by this time. I think that the total scope of supply for 2009 is smaller for all suppliers in the offshore industry. On the other hand, we have been rather successful in spite of this; in the first two months of 2009 we have had orders that will cover more than one years production already. It is a big accomplishment to increase our market share in a demanding environment.”

Concluding, he says: “We are currently expanding our capacity and will continue to do so, with the next investment occurring within the next three months. We are also looking into offering more products. In the coming five years we will have a broader scope of supply; today we have mooring chains and shackles, and we would like to have more products in the mooring chains systems and services area, looking into services such as chain inspection.”

As the result of an ambitious investment programme, which has mainly focused on productivity enhancement measures, the company is well equipped to maintain and further strengthen its position as one of the world’s leading manufacturers of heavy chains for the offshore industry. Equally, its knowledge of the offshore industry will contribute to further success in the future. Although financial conditions are not ideal, the business will remain strong by further developing and broadening its operations to include total system solutions for the anchoring of oil platforms.

Ramnäs Bruk

Products: Anchor chains