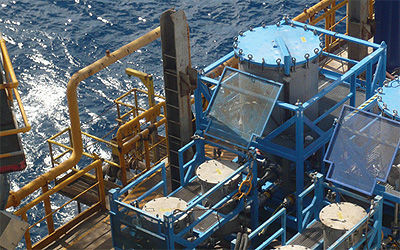

Established in 1985, Twin Filter designs and manufactures a wide range of filtration equipment and consumables for the offshore industry

The complete solution

For over two decades the company has built a reputation for delivering complete filter packages for activities such as water injection, produced water treatment and completion fluids filtration to many of the key players in the oilfield services sector. Its work in the area accounts for approximately 70 per cent of Twin Filter’s operations, with it also supplying equipment to the chemical, electronic, pharmaceutical and food and beverage markets.

Detailing the main strengths of the organisation, Eric Wals, the sales manager of Twin Filter, says: “We are a company that fully understands the oilfield business. There are many others out there who know about filters and how to filter water but they don’t know how to serve customers in the industry or how to work on a global basis. We are not just a manufacturer but also a provider of total solutions – not just the filter cartridge but the equipment that surrounds it. The team has the relevant knowledge and knows how best to apply it and we have people constantly training in the field, that really sets us apart from some of the other companies.”

One of the main staples of the product portfolio is the equipment for produced water treatment. With all oil and gas fields producing water and condensate oil and gas during production, the need for high levels of separation and absorption is required before it is discharged overboard. Twin Filter supplies systems that make it possible to discharge to the required levels both on-site and in an  environmentally friendly way. “Produced water treatment has become much stricter on a global basis, you’re not allowed to simply dump fluids anymore. As the various sectors have developed, more and more water is being produced, even more than oil, so it is very important that it is properly treated,” says Eric.

environmentally friendly way. “Produced water treatment has become much stricter on a global basis, you’re not allowed to simply dump fluids anymore. As the various sectors have developed, more and more water is being produced, even more than oil, so it is very important that it is properly treated,” says Eric.

The use of completion fluids filtration has also become essential in the quest to maximise the potential of oil and gas reserves. The practice removes dirt particles from the resources that have an effect on the permeability of any given source. Twin Filter has been an authority on advising, engineering and manufacturing a complete package of filter equipment and consumables in the field for over a decade. Commenting on the trends in the area, Eric explains: “The complete fluids operations are increasingly carried out in deep sea conditions, which means larger volumes of fluids. Companies have to be very efficient to maximise production and the oil fields must be kept clean.”

Water injection makes up the third pillar of Twin Filter’s services for the offshore industry. By using the equipment, companies in the oil and gas sector can significantly increase the productivity of existing oil wells. It is thought that a reservoir is likely to produce just 37 per cent oil in its first recovery – the use of a water injector in the process can boost that figure to over 50 per cent. As well as improving the ratio of usable reserves to waste, the water injection treatment systems are guaranteed to deliver clean water. It is an area that the company is currently undertaking a major assignment in. “We are working on a significant water injection project at the moment. We have been awarded the contract to manufacture 16 high pressure filter units and they are scheduled to be delivered to the company in the next couple of months,” reveals Eric.

As you would expect with such complex and crucially important systems, Twin Filter works side-by-side with its customers during the development phase. “A lot of what we produce is tailor-made for our clients,” says Eric. “We have many key supplier agreements with companies all over the world to produce their consumables and equipment. Because of the number of custom-made projects we have we always look to run tests with our customers. We also invest in R&D; at present we are pulling together some of our technologies for produced water treatment so we are able to offer our clients a greater choice of solutions.”

Looking forward, he is understandably positive about the future and is keen for Twin Filter to increase its standing in the oilfield sector. “There is certainly the opportunity for big potential growth in the produced water treatment sector because the market is so big. There is a willingness on the company’s part to expand in that area. The conditions of the market, in both the oil and filtration sectors look very good, it is becoming more important to get more oil from each reservoir. For that more filtration and clean water is needed – that is clearly a positive for us,” says Eric.

If that prognosis of the industry is true – and all the evidence suggest that it is – then his vision for Twin Filter to become “a big player in the filtration sector of the oil and gas industry” should come to pass sooner, rather than later.

Twin Filter

Products: Filtration equipment and consumables