Fluenta AS

Adding a little flare

Fluenta is a Norwegian company that works with its clients to enhance flow rates in gas pipes, primarily through advanced measurement devices in flare stacks.

Having been around since the 80s and experienced two ownership changes, it is currently an independent firm with customers across the world. It has recently upgraded the software on its monitoring system with an algorithm that subtracts nitrogen volume from the total through flow, and is currently working on the next generation of its system.

Initially founded in 1985, Fluenta was born out of the Christian Michelsen Institute’s research and development (R&D) into flare gas metering. In 1987 the company began what would become a long-term relationship with Norwegian offshore operator Statoil with the installation of monitoring systems in its Karstø processing plant and North Sea oil platform Gullfaks C. After establishing itself as a leading flow rate monitoring specialist, the company was bought by Roxar in 2000; by May 2007, however, Roxar decided to spin off its flare metering arm and Fluenta was bought by Roxar’s then global sales director, Dag Johansen.

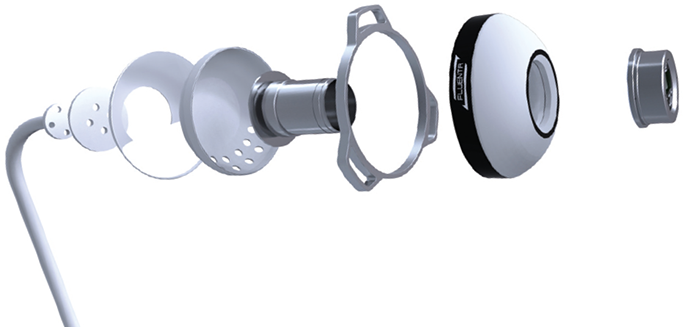

Today, Fluenta specialises in a single flare-metering product known as Flare Gas Meter (FGM) 160, whose purpose is to measure flare gases in complex and challenging environments. By using transducers mounted within the pipe that measure the time it takes for an ultrasonic pulse to travel from one probe to another – with faster streams making pulses travel slower – the system is able to calculate the velocity of travelling gas. This is known as the time-of-flight method.

Dag Johansen, who is now at Fluenta, explains one of the core strengths of the company’s technology: “Our probes are non-intrusive, meaning they don’t interfere with the flow process. Because they are flush against the pipe wall it also means that the probes themselves aren’t being contaminated or stressed whilst in use, achieving a significantly longer lifetime than other products.”

Recently added to FGM 160 is an algorithm developed in conjunction with Statoil to account for the use of nitrogen in gas pipes. Flare stacks are located by gas wells and serve two purposes: firstly as a safety valve, ensuring pipes do not over-pressurise, and secondly to eliminate waste gases by burning them off. This process of burning, however, lowers pressure in the pipe so operators increase pressure again by adding nitrogen.

Recently added to FGM 160 is an algorithm developed in conjunction with Statoil to account for the use of nitrogen in gas pipes. Flare stacks are located by gas wells and serve two purposes: firstly as a safety valve, ensuring pipes do not over-pressurise, and secondly to eliminate waste gases by burning them off. This process of burning, however, lowers pressure in the pipe so operators increase pressure again by adding nitrogen.

Dag discusses the reasons behind needing to calculate nitrogen volumes: “It is an issue because an increasing number of countries are now introducing emission taxes. These tax figures are based the measurements from our system on the amount of gas that flows through the pipe. However, nitrogen is used to maintain pressure in the pipe and until recently there was no way to separate it from other gases; flared nitrogen is  not environmentally dangerous so operators had concerns over paying for it. Together with Statoil, we developed an algorithm for FGM 160’s software that subtracts the volume of nitrogen from the total flow. This is invaluable because clients based in countries with emissions taxation are better able to control their flaring and so save a huge amount of money.”

not environmentally dangerous so operators had concerns over paying for it. Together with Statoil, we developed an algorithm for FGM 160’s software that subtracts the volume of nitrogen from the total flow. This is invaluable because clients based in countries with emissions taxation are better able to control their flaring and so save a huge amount of money.”

Although Fluenta does not engage in bespoke manufacturing, it offers two different models of its product to meet the different needs of its customers. The FGM 160 is used both onshore and offshore, with the latter having much more accurate and complex requirements than the former. This commonly results in onshore plants being provided with a stripped-down, more cost effective version of the FGM 160. Fluenta always talks with the client before selling to them, however, and onshore plants will sometimes opt for an offshore version.

With just a single product in its portfolio, Fluenta is able to focus all its R&D on FGM technology. A continuing programme of development sees not only incremental upgrades such as the nitrogen analysing algorithm but a completely new generation of platform every four years. FGM 160 is the company’s third generation technology and, over the 12 months, it will be launching the fourth generation. It will tackle metering problem areas such as high temperature and high-pressure environments, providing not only more effective operation in existing pipe markets but also opening the company up to the gas transport market.

Another upgrade that Fluenta is looking to create is the ability for the FGM to measure CO2 content. “CO2 injection has become popular method to enhance oil recovery from reservoirs,” Dag comments, “but because it is a dense gas there is an impact on sonic measurements. Our challenge is to be able to measure concentrations of CO2 of up to 80 or 90 per cent. Much like with nitrogen calculations, it means companies can be more shrewd in their measuring and use of flare stacks.”

Because Fluenta does not have its own R&D department, all of this development is carried out in co-operation with American and Norwegian universities. More recently it has also received financial help from Innovation Norway, the innovation research branch of the Norwegian government, as well as from Brazilian-based energy company and long-term partner Petrobras.

With the support of governmental bodies and multinational corporations behind it, as well as customers throughout the world, Fluenta looks to have a bright future. Dag concludes confidently: “The company will continue producing technology with a green profile and over the next five years I can even foresee us moving into the area of water monitoring. That is a natural development for the company. Fluenta has developed for operators and will continue doing so in the years ahead.”

Fluenta AS

Services: Gas flare measurement systems