Fluid Control Services: A Decade of Excellence in High-Pressure Solutions

Pumping progress

Working under the motto ‘Your Vision Our Goal,” Stavanger-based, Fluid Control Services is renowned for quality, reliability and premier customer service.

Conducting all of its operations under a ‘cando’ approach, the company is highly focused on meeting its customers current and future demands, with a core business offering that consists of sales, service, rental, engineering and production.

Founded in 1998, the company has grown to become an experienced, fully integrated business, serving the oil industry with a range of products and services, including check valves, hammer unions, plug valves, swivel joints, loops, tees, pup joints, butterfly valves, chokes and relief valves. Introducing the business, manager Arve Haaland begins: “We are a Norwegian-owned company that has been working on the rental and sale of high pressure iron treatments for the past ten years. While offering roughly 10,000 items for rent and customer owned equipment, we also produce our own equipment, with CNC machines helping us to offer the complete process from bare steel through to the finished product in-house.”

Expanding on the company, Arve continues: “We are an agent for SPM, Flow Control Inc based in Fort Worth Texas, we have been working with them since the beginning. SPM are one of the three large manufacturers of this equipment in the world, Fluid Control Services is agent in Norway and Denmark. Our main customer is Halliburton and Expro and they represent a large proportion of our turnover.”

The importance of Halliburton is emphasised by Fluid Control Services’ list of engineering services, which includes a specially-made Halliburton hose reel that has been rebuilt for the customer,  from chain drive to direct hydraulic drive with reduction gear, with an almost completely rebuilt level winder. The company’s other engineering services include a hydraulic remote operated valve, hose reel power packs, fully automated pulse dampeners, and air remote operated valves, as well as its modifiable hose reels.

from chain drive to direct hydraulic drive with reduction gear, with an almost completely rebuilt level winder. The company’s other engineering services include a hydraulic remote operated valve, hose reel power packs, fully automated pulse dampeners, and air remote operated valves, as well as its modifiable hose reels.

Discussing the customised nature of the company’s service, Arve says: “If our clients have a special need, our in-house engineers are able to modify all of our standard equipment so that we can deliver a complete package to them in reasonable time. If there is something that they need that does not come as a standard from SPM, this ability to create a complete, customised package is one of our particular strengths.”

A part of this complete package is after-sales servicing and repair. Taking seven days, its general service consists of visual checks, cleaning, greasing, leakage repairs, pressure testing and spot painting, while the major recertification, which can take up to 21 days, also includes sandblasting, parts changes, MPI, wall thickness checks and pressure testing.

“When working on customer-owned equipment, we handle it as if it is our own, offering a thorough service that includes taking care of all of the documentation,” explains Arve. “Basically our service is split into two areas; handling customer-owned equipment, offering services including packing and storage, and renting equipment out to clients.”

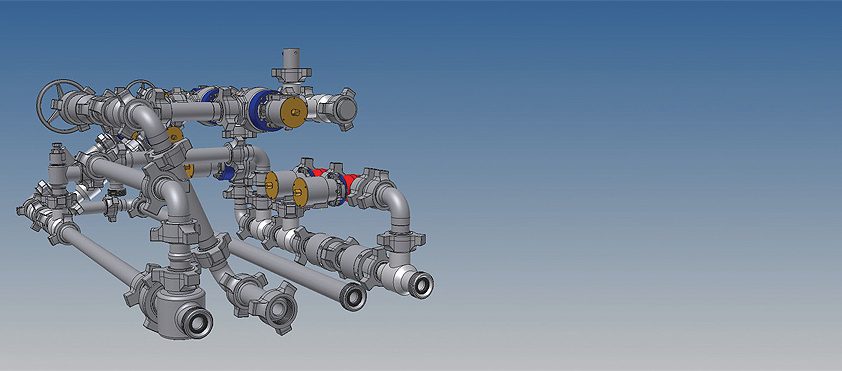

With a rental fleet that consists of some 10,000 items, this is a significant part of Fluid Control Services’ business, as it offers chicksan containers, safety restrain systems, hydraulic power packs, hydraulic torque wrenches and manifolds. The company has been building foam/defoam manifolds to meet customer specifications for many years, with clients able to approve a model from an expansive 3D library of chicksan equipment, before the fabrication of the customer-specific parts begins.

To ensure that the business is able to meet the demands of its customers, both in terms of rental and client-owned equipment, Arve explains that there is a constant focus on R&D: “This is happening all year round, with a new project always going on. For instance machining is fairly new to us, while we have also started welding all types of materials that we are involved in, and have began producing larger hose reels.”

While it is always essential to continue developing the company’s service to stay ahead of the competition, it is currently an issue of particular importance due to the high potential of the market. “We are on course to have our best year ever, and expect the next two years to be even more successful,” comments Arve. “We may also look to expand out of Norway and move into Africa, because our customers want us to join them there.”

With significant potential for further growth, the business is in a strong position, and through its mix of quality, reliability and premier customer service, it is on course to reap the rewards of a buoyant market. Summarising, Arve concludes: “Fluid Control Services delivers a complete package to our customers, from inhouse equipment, with a full range of hoses and welding, through to documentation. We want to be the best in our field, and will continue to offer the best possible levels of customer care.”

Fluid Control Services

www.fluid-control.no