Framo Engineering AS

Boosting recovery

With demand for oil and gas products continuing to rise on a global basis, the time and expenditure required in developing new fields means that the ability to enhance recovery from existing sites is becoming ever more sort after.

However, developments into deeper waters, more viscous oil reserves, longer tie-backs, and mature fields all bring with them their own recovery challenges. Since it was established in 1983, Framo Engineering AS has retained the same vision of developing leading-edge technology for the oil and gas industry, as a systems supplier of enhanced recovery products.

Today the Framo Engineering name is synonymous with enhanced recovery and marine system technology, including subsea pumps, pump controls, multiphase and wet gas flow meters, compact manifold, swivel stack systems, fluid transfer systems, and providing ‘best in class’ technological solutions that meet market needs. Its focus is to work closely with its clients for the whole field life of a product, from the concept phase to project execution and after-market support, assisting in optimising their interests.

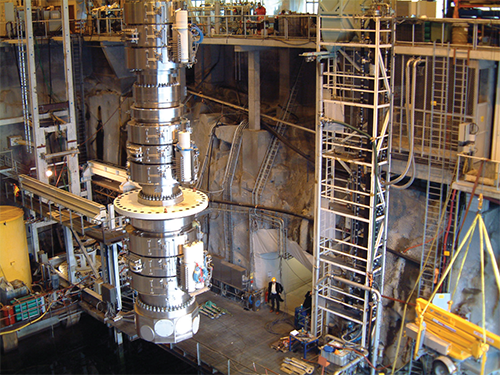

“Over the last two years we have developed a range of boosting pump systems that all have different properties but can be installed onto the same subsea interface,” elaborates Ole G.Steine, managing director. “Oil fields are either gas or water driven and this changes the requirements for the pump technology, so we have developed a range of products from single phase to hybrid, as well as a very high pressure multiphase pump. We have also invested enormously alongside Statoil in the development of a unique new wet gas compression (WGC) system. This is a huge five megawatt system designed to boost wet gas production, without the need for any separation. Having conducted extensive live testing with oil and gas, we are hoping to implement the WGC system in its first commercial application in one of Statoil’s North Sea interests.”

Another prominent development within Framo Engineering is the Offshore Cryogenic Transfer (OCT) system. The OCT is designed to help harness the commercially lucrative associated gas found with oil reserves, which previously was either flared or was reinjected as a pressure support in the production of oil. Given the offshore location of these fields transportation of this gas asset in its natural form is difficult – however utilising a floating liquefied natural gas (FLNG) production facility on top of the well itself, the gas can be converted into LNG and using the OCT system transferred into a shuttle tanker.

Framo Engineering has been working on this revolutionary system for the last 13 years within a group of specialist companies, each bringing their individual expertise to the project. Highlighting the benefits of the OCT system, Magnus Bernson, area sales manager, comments: “Currently LNG transferred on and offshore is carried out via stiff hinged arms connected to  the tanker, which is moored alongside the jetty or offshore installation. However this has limited application offshore as in waves of over 2.5 metres the relative movement between the two units is too high and the system cannot be used. The OCT system is targeted at offshore installations located in harsher environments, with the tanker connected in tandem to the facility via a special crane arrangement with flexible pipes, as opposed to side by side. As they are not connected physically, the two vessels are able to move individually providing much greater flexibility and a wider operational window in even high wave conditions.”

the tanker, which is moored alongside the jetty or offshore installation. However this has limited application offshore as in waves of over 2.5 metres the relative movement between the two units is too high and the system cannot be used. The OCT system is targeted at offshore installations located in harsher environments, with the tanker connected in tandem to the facility via a special crane arrangement with flexible pipes, as opposed to side by side. As they are not connected physically, the two vessels are able to move individually providing much greater flexibility and a wider operational window in even high wave conditions.”

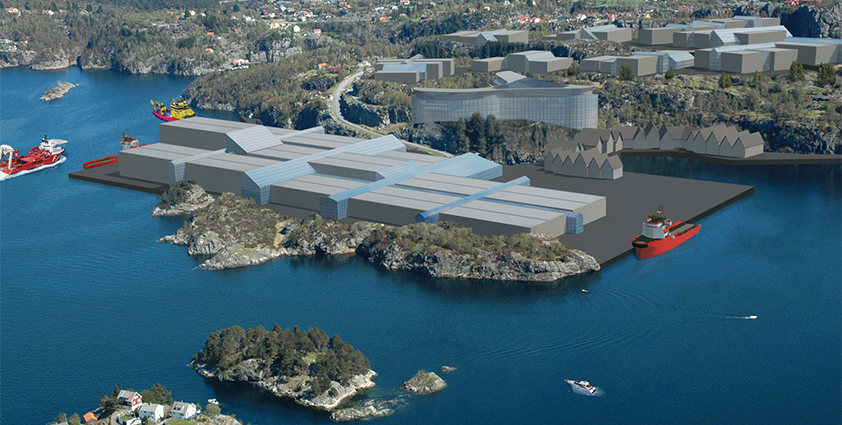

This year also sees Framo Engineering moving into a new 30,000 sq m facility on an island close to its current location in Bergen, Norway. This is the first phase of development, including a 210 metre deep-water quay and 320 tonne crane, with the island’s total area of 600,000 sq m providing substantial capacity for further expansion. Considering that this significant investment took place during the difficult economical years of 2009 and 2010, Ole describes the reason driving the development: “Gathering all of our activities together in one location makes a lot of sense from a commercial and internal processes perspective. It enables us to remain competitive in the international market through the standardisation of our solutions, products, and processes, as well as providing an attractive workplace for our employees.”

Certainly the benefits of Framo Engineering’s product range should not be overlooked, particularly when you consider that the right system can substantially enhance oil recovery resulting in a longer life span for mature fields, and prevent fields being abandoned prematurely due to a drop in recovery rates. With high levels of activity in America, Australia, Angola, Brazil, and the Gulf of Mexico predicted for the near future, take-up of Framo Engineering’s expert solutions seems set to rise.

“I believe there is tremendous potential for good quality products in this market, and with 1.2 million hours of operating experience with booster pumps our systems have been proven in the commercial market. I also see an increase in the multi-phase metering aspect of the business as this enables operators to know what they are producing and therefore how they can optimise this. In addition to our WGC and OCT developments, we have also delivered smarter loading systems to Shell in Norway. This is a submerged system, which has a stiff riser instead of the traditional flexible riser. We have spent the last few years securing our position for the future, and as operators continue to realise that by using our proven systems to reduce back pressure they can produce oil for longer and the enormous financial value of this increase, we see a lot of potential for the business,” concludes Ole.

Framo Engineering AS

Products: Recovery systems