GCG Shotblasting Services: Innovating Coatings for Oil & Gas Industry

Listening to the market

Gerard Gaffney, George Watson and Charles Lawson formed GCG Shotblasting Services Ltd (GCG) in 1985.

Today it provides a vital service to the oil, gas, renewable energy, decommissioning, water and chemical industries, protecting steelwork, equipment, pipework and structures subjected to erosion, corrosion and chemical attack.

The main sectors that GCG services are oil and gas and renewable energy, carrying out work for the operators as well as second tier companies and fabricators, but that isn’t definitive, as Michael Gaffney, executive director at GCG, explained: “We also provide a service to the Decommissioning, Agricultural and the Pelagic sectors.”

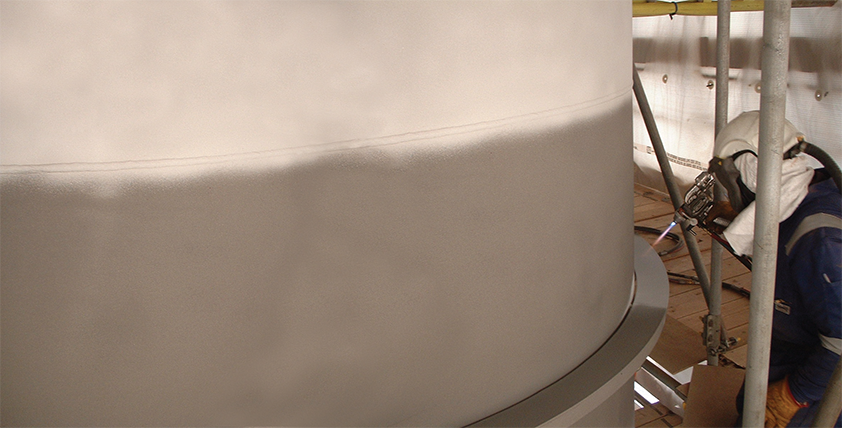

He goes on to give a few examples of GCG’s products: “Our core products are standard epoxy coatings, Intumescent coatings, TSA (Thermal Spray Aluminium) and Passive Fire Protection. We also have a new product we are looking to launch early in April 2013, called PPC553, which is a specialist coating. This product is going to change the oil and gas market significantly. It has a cure time of six seconds, and it can be applied to minimal prepped steel and you are looking at a life span of approximately 40-50 years. The product is long-lasting, fast-drying and requires little maintenance.”

This product was developed in direct response to requests from the market, and is designed to offer protection against corrosion and erosion on a North Sea platform. “It will save oil and gas operators a significant amount of money because of the cost of shutting down a platform while we do maintenance,” said Michael. “In scenarios where generic epoxy/polyurethane paints are currently used on offshore platforms, clients are lucky to get five to seven years life before they are doing maintenance again. With the new product they won’t have to look at it again for at least 40 years, thus saving them millions in downtime costs.

“It also has a substantial health and safety benefit, corrosion and erosion is a severe problem especially in the North Sea, and this new product extends the actual structural integrity of the offshore platforms far beyond standard coatings. It has a bundle of overall benefits for end users and also for us as a company. With the material being solvent free therefore having zero VOC’s and CFC’s it is very much compatible with our essential environmental policy.”

As this new product is regarded as so important, naturally GCG is focusing a lot of effort on publicising its launch. “We have already had quite a bit of interest from three key oil and gas operators,” noted Michael. “All three are looking into it quite seriously and we are working with them to gain specification approval, plus outside of oil and gas there is a major drinks manufacturer, one of the biggest in the world, who has requested several demonstrations and has shown a great deal of interest.”

He added one more benefit of PPC553: “I think this new product will help us in terms of expanding into different markets, possibly the Middle East and South America.”

PPC553 offers lifetime asset protection

PPC553 offers lifetime asset protection

“This is a big year for us – we have just moved into new offices and have invested a great sum of capital in up-dating/improving our on-shore facility and we are now looking to expand internationally. We are currently working on a tender for a project in Australia.”

A recent contract has seen GCG working on a new project off the coast of Shetland alongside a major worldwide operator. “We were working on very large structure steel subsea frames, that were primarily through one of the fabricators we do a lot of work for,” explained Michael. “Another project we are working on at the moment is a vast amount of pipe work for a Dutch Oil & Gas operator for a Major North sea Platform.”

As well as working on newly fabricated steel, GCG also offers refurbishment services, and Michael is keen to illustrate the benefits this approach can bring: “In my eyes this service can be linked to decommissioning, which is a big and growing market. The way I see ourselves being involved is not with ‘decommissioning to scrap’, which is currently on-going, but is more of a ‘decommission to reuse’. We are trying to emphasise to operators that if they have to decommission some of the projects offshore, why not refurbish them instead and reuse them for future projects.

“We already class ourselves as experts in thermally sprayed aluminium (TSA). We have been applying TSA for well over 20 years and we have been applying it on live gas sites for over ten years – we were one of the first companies apply it to a live gas environment in a safe and productive manner.”

All indications are that the next five years will see a growing demand for offshore maintenance including the renewal of much of the steelwork to improve its integrity. Michael is confident that the company is ready to meet the demand: “We are account managed by Scottish Enterprise and they have been helping us to grow steadily. We are looking to take on a significantly higher number of specialist employees over the next year and a half.

“It is quite difficult to find the right skilled labour, so we have developed a very good in-house training department and we are working with our local college to establish a formal traineeship.”

As part of the launch of PPC553 GCG will have a stand at Offshore Europe for the first time, as part of the Aberdeen City and Shire Pavilion and will be using the event to make contact with potential customers from around the world. It is also re-launching its website to include detailed information about the new product.

Given the predictions that Michael mentioned for increased activity for GCG, this period could be viewed as the calm before the storm, and the company is wisely using it to be ready to take a market leading position.

GCG Shotblasting Services

Services: Corrosion protection

PPC553 offers lifetime asset protection

PPC553 offers lifetime asset protection