Global Engineering Excellence in ClydeUnion Pumps

Unified position

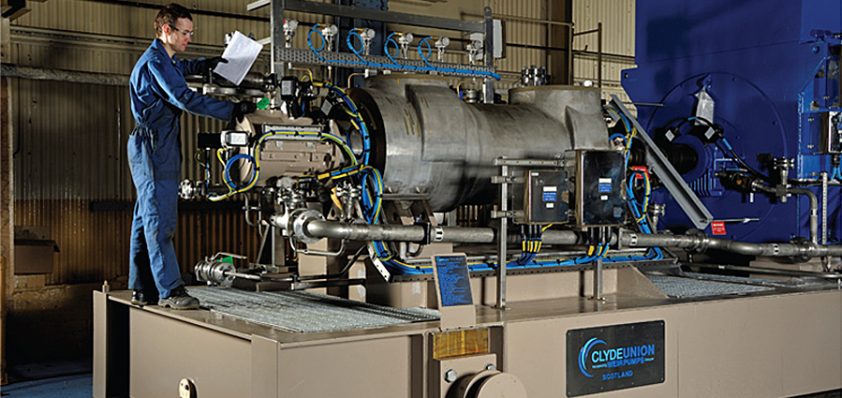

ClydeUnion Pumps is one of the world’s leading pump companies, with proven expertise in hydraulic design and specialised mechanical engineering focused on highly engineered pump packages.

The company is structured into seven business units specifically targeting each of the key markets its clients operate in, upstream oil, downstream oil, nuclear power, conventional power, water and industrial, the newly formed mining and metals and finally aftermarket. ClydeUnion, as it stands today, was formed through the integration of two pump manufacturers from either side of the Atlantic – Clyde Pumps and The Fluid & Power Division of Textron. Although Clyde Pumps was formed in 2007 when Clyde Blowers acquired Weir Pumps (Glasgow) from the Weir Group plc, Weir Pumps’ history actually stretched back to 1871. In 2008 Clyde Pumps’ acquisition from Textron included Union Pumps, comprising the heritage pump brands of Union Pump, David Brown and Pompes Guinard, the earliest of which has been producing high quality pump products since 1885.

The company has five major manufacturing sites in Canada, the US, France, and the UK, three joint ventures in India, Brazil and China and a global spread of strategically located service centres and sales offices providing support to customers around the world. Its largest facility is located in Glasgow, UK, which produces centrifugal pumps for all business sectors but specialises in products for the upstream oil and nuclear power industries.

Within its upstream oil division ClydeUnion provides engineered pumping solutions for some of the harshest applications in the oil and gas sector in onshore and offshore environments, in production, in-field treatment and transportation and storage. By way of an introduction Ian Morrison, managing director of upstream oil and gas, says: “In terms of upstream oil, in consolidating the Clyde Pumps and Union Pumps products we now have a world class range of pumps fully meeting the needs of the oil and gas industry, which, along with our expanding footprint around the world gives us a fantastic platform for increasing our competitive participation in the global oil industry.”

He continues to describe the key strengths of the business: “We have a strong tradition in working in difficult environments offshore, with pumping equipment such as produced water re-injection, high reliability submersible sea water lift and crude oil export machines. Now that the Union Pump products have been integrated within our portfolio we are able to produce a package to meet the pumpingrequirements of any given upstream oil project. We have some key enabling products such as our HSP, a hydraulically driven downhole pump, which is being utilised very successfully by Chevron on its Captain Project in the North Sea. The HSP provides huge operational benefits in terms of reliability and availability in service delivering a mean time between failure in excess of ten years. It is exceptional performance in such an arduous application handling heavy oil with variable mixes of water and gas.”

Recent major orders include ClydeUnion’s first contract for pumping equipment for the oil field developments in Iraq for Shell’s Majnoon project, for which it will supply $5 million of injection and oil export pumps, a breakthrough in Calgary where it has secured in excess of $12 million of pumping equipment for ConocoPhillips’ Surmont II Oil Sands SAGD Project as well as its $8 million contract for sea water injection pumps for ADMA-Opco’s Zakum field upgrade in Abu Dhabi. Added to this is its $6 million contract for engineered pump packages for Kebabangan Petroleum in  Malaysia. It is also completing major pumping contracts for BP in Angola, Noble Energy for Equatorial Guinea and for Sonatrach in Algeria.

Malaysia. It is also completing major pumping contracts for BP in Angola, Noble Energy for Equatorial Guinea and for Sonatrach in Algeria.

ClydeUnion’s comprehensive range of API 610 compliant centrifugal pumps are used in a wide range of applications. The company’s experienced in-house engineers are continuing to develop the existing products and each pump range, as well as new products to meet the changing needs of the market and enhance its offering to its clients. “Such developments include extending our centrifugal and reciprocating pumps to meet the increasing pressures needed for deepwater and shale gas production as well as hydraulic designs suited to specific processes in offshore sulphate removal or emulsion pumps in SAGD. Of course one of our core strengths is our ability to produce complex engineered packages,” highlights Ian. “We are able to engineer and bring together not only pumping equipment but also the necessary components to produce a tailored solution for the particular client specification.” Each ClydeUnion product is fully supported by a committed aftermarket team providing a service wherever the product is installed in the world, including spare parts, overhauls, upgrades and comprehensive technical advice.

With a reputation for developing reliable and efficient products, ClydeUnion undertakes dedicated research and development within its own in-house laboratory. Through a combination of its culture of innovation and customer-centred approach ClydeUnion is able to tackle even complex technical challenges. “R&D is a critical part of our product development, including components development and identifying improvements that will ensure our products continue to provide excellent availability and reliability in service. Currently our efforts are principally focused on the expansion of our product range and improvement of hydraulics to deliver greater efficiency to clients,” explains Ian.

Recently ClydeUnion expanded its capabilities again with the acquisition of S&N Pumps. Ian describes the investment: “ClydeUnion’s current activities are within the conventional exploration and production environments, whereas S&N principally specialises in offshore drilling services. The acquisition provides us with greater access to the whole of the upstream oil industry and the synergies between S&N and ClydeUnion’s mean that our portfolio is strengthened through complimentary products. S&N also has facilities in Angola, Dubai and Singapore, which provides us with a platform to develop into new geographies. We will be working closely to utilise our combined knowledge and experience to grow our seawater lift and firewater pump offering across the sector.”

This year ClydeUnion also won the Scottish Engineering Award for Company of the Year, which took into account the company’s improvements and investments in its manufacturing capabilities, as well as its working relationship and development of its employees. Particularly following the challenges of the last year after the economic downturn, this award is a real testament to ClydeUnion’s engineering capabilities. “Although last year was difficult across both the market sector and the pump industry, the integration of the products, sales teams, facilities and Joint Ventures is really starting to deliver improved performance across our business. In 2010 we will deliver a doubling of our sales input over 2009 and plans are in place for further growth in 2011,” says Ian.

Following on from these positive figures he concludes with the future ambitions of the company: “Naturally we want to be a customer-preferred supplier of engineered pumping equipment for the upstream oil and gas market, and to retain our leading status. We will continue to develop our global operations so that we have product and industry expert staff in all our key regions with the appropriately located manufacturing sites fully supporting our customers on a local basis. As an overall company we have a vision for ClydeUnion to become a $1 billion company by 2011, and with the acquisition of S&N Pumps and the combined expertise across the group, we are well on the way to achieving this target.”

ClydeUnion Pumps

Products: Pump solutions