Hayward Tyler: Driving Growth and Innovation in Oil & Gas with £1M Modernisation

Pump up the volume

It has been a productive and successful year since world-renowned designer and manufacturer of fluid filled electric motors and pumps Hayward Tyler was last featured in European Oil and Gas Magazine.

Viewing reduced activity in 2011 as an opportunity to overhaul the business, the company embarked on a range of initiatives to enhance the efficiency of its supply chain logistics and production to provide more customer-responsive and cost effective operations. Following a lengthy preparation and planning period, Hayward Tyler began putting its £1 million modernisation programme into action in early 2012, which is already proving highly successful. By maintaining a state-of-the-art production line and flexible supply chain the company can now take on larger contracts with ease.

“We have made significant progress in terms of re-structuring our main manufacturing operation in Luton, which began in 2012 and is a continuing improvement journey in terms of our people, processes and products,” explains Ewan Lloyd-Baker, Hayward Tyler Group’s chief executive officer. “Our order intake across the board is up 42 per cent at £13.9 million in comparison to the first quarter of last year due to significant order wins in the offshore oil and gas exploration market. We have also been developing our relationship with Eureka, the largest supplier of pumps on the Norwegian shelf, it is a partnership based on experience and a mutual dedication to reliability; I am delighted that we are working together.”

Already the preferred supplier to major oil and gas firms such as Aker and GE Oil & Gas, the company’s relationship with Eureka will further expand its foothold in this market with a focus on smaller-sized underwater units and their maintenance. This initiative follows both firms jointly winning orders of 14 units for the Eldfisk, Aasta Hansteen and Martin Linge projects in the North Sea; worth more than £3.5 million to Hayward Tyler, which will bring the number of Hayward Tyler submersible motor units in the North Sea to almost 150. “Previous to this, we won a £2.7 million contract for a range of sea-water lift and firewater pumps for the Hebron field, off the coast of Newfoundland. This contract was awarded to us by Eureka and was an important oil and gas win for us,” adds Geoff Robinson, projects director. “Ultimately we go where the end customers go, although we are certainly focused on the Norwegian sector, we also export to Canada, Malaysia, Thailand and other locations around the globe.”

Established in 1815, the company has a long and distinguished history of innovative designs and engineering excellence, inventing the first submersible electric motor in 1908. This product became integral to the global mining industry, while its high-pressure pumps went on to be utilised in nuclear power stations. Today, Hayward Tyler is keen to continue delivering solutions to ever-changing challenges in the fossil-fired or offshore upstream oil and gas market through constant design improvement. “Our main strength is our brand as we have a fantastic reputation for reliability within our particular markets; we sell our customers a promise and over the last few years we have strengthened our position to deliver this through continuous improvement,” says Ewan. “We have rolled out 5S training to all our staff, on-the job training to our apprentices and professional subjects through courses such as MBAs for our senior managers. Our master scheduling capability is being recognised as world class by our peer group and now the focus is on how we can enhance our research and development to create the next generation of products.”

Established in 1815, the company has a long and distinguished history of innovative designs and engineering excellence, inventing the first submersible electric motor in 1908. This product became integral to the global mining industry, while its high-pressure pumps went on to be utilised in nuclear power stations. Today, Hayward Tyler is keen to continue delivering solutions to ever-changing challenges in the fossil-fired or offshore upstream oil and gas market through constant design improvement. “Our main strength is our brand as we have a fantastic reputation for reliability within our particular markets; we sell our customers a promise and over the last few years we have strengthened our position to deliver this through continuous improvement,” says Ewan. “We have rolled out 5S training to all our staff, on-the job training to our apprentices and professional subjects through courses such as MBAs for our senior managers. Our master scheduling capability is being recognised as world class by our peer group and now the focus is on how we can enhance our research and development to create the next generation of products.”

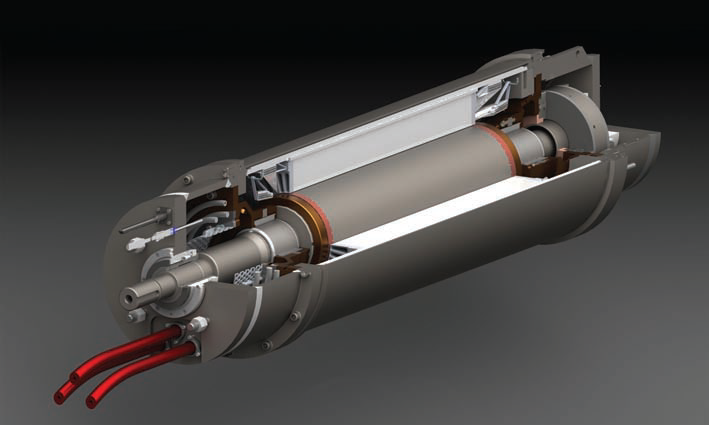

The company’s low maintenance and long life subsea motors have been developed to meet the most challenging power, voltage and pressure requirements, offering peace of mind across seawater injection and subsea boosting applications. Accommodating pressure changes, the mission critical subsea motors also include duplex or super duplex stainless steel shells to ensure reliability and protection against harsh environments. Furthermore, a ‘uniform electric field’ minimises electrical stress, thus offering a long winding cable life, while an external heat exchanger and intricately designed internal flow pattern enables the optimal operating temperature to be achieved.

With Eureka the largest supplier of pumps on the Norwegian Shelf, having sold more than 2000 units to Statoil alone, collaboration in terms of product development is likely to lead to increased growth in the oil and gas sector for Hayward Tyler, as Geoff highlights: “One thing we are working on together is the reduction of lead times to our target of circa 35 weeks and also highlighting the benefits of using the OEM in reducing the total lifecycle cost of ownership. We provide solutions that are going to last decades because we know you can’t get reliability without quality.” Dependent on each customer’s requirements, Hayward Tyler designs to the most exacting standards such as ASME PED, TUV, IBR and Norsok and provides products and services for applications where the focus is on high pressure, high temperature or difficult to handle fluids.

Having set strong foundations in innovation and reliability for nearly 200 years, Ewan is confident about Hayward Tyler’s ability to continue providing its customers across the entire energy sector with technological solutions. “Having seen significant growth over the 2013 financial year across most areas of the business, we are looking forward to our 200th birthday with increasing confidence. Within oil and gas we see significant opportunity in the North Sea, however as 85 per cent of our business is export we are looking at areas such as West Africa, Brazil and South Africa to help support this growth,” Ewan concludes.

Hayward Tyler

Services: Designer and manufacturer of ‘mission critical’ motors and pumps