Howco Group masters complex materials to power global industries with incomparable precision

From 11 locations in six countries across four continents, the Howco Group manufactures and distributes high-performance alloys and components for deployment in the world’s most challenging scenarios, conditions, and locations. These products are particularly crucial for companies in the oil, gas, chemical processing, and energy sectors, where precision and reliability are paramount. Howco’s overarching goal is to limit service disruption, downtime, and costs for its customers, thereby ensuring seamless operations. Jane Savage, Commercial Director of the European Distribution Division and Michael Smith, Director of the UK Manufacturing Division, join us for a discussion around the company’s core operations and latest developments.

Considered a market leader with over 40 years of experience, Howco is one of the world’s largest processors and distributors of nickel, stainless, and low alloy products for the global energy industry. From its humble roots in Scotland, the organization has grown, diversified, and constantly adapted to the ever-changing needs of its customers and the overall industry to become what it is today. In 1982, the business was established as a metal stockholder and now spans the globe across six countries with a mixture of distribution and precision manufacturing sites. Howco became part of the Sumitomo Corporation in 2006, which is one of the world’s largest trading companies.

Considered a market leader with over 40 years of experience, Howco is one of the world’s largest processors and distributors of nickel, stainless, and low alloy products for the global energy industry. From its humble roots in Scotland, the organization has grown, diversified, and constantly adapted to the ever-changing needs of its customers and the overall industry to become what it is today. In 1982, the business was established as a metal stockholder and now spans the globe across six countries with a mixture of distribution and precision manufacturing sites. Howco became part of the Sumitomo Corporation in 2006, which is one of the world’s largest trading companies.

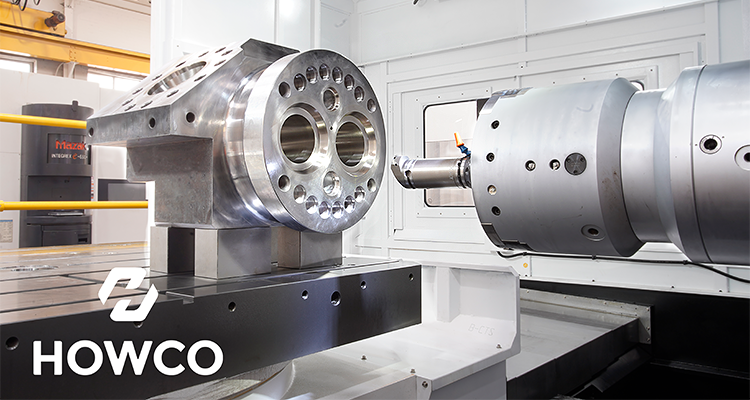

We ask Jane and Michael about the range of products and services Howco provides in both the Eastern and Western Hemispheres. “In terms of distribution and processing, we provide a full range of nickel, stainless, and low alloy products, along with conversion services like first stage machining, forging, heat treatment, and testing. Additionally, our manufacturing operations encompass a comprehensive range of precision CNC machining together with full hydrostatic and gas pressure testing capabilities. Products range from bespoke single piece items to batches or families of components for utilization in our full assemblies of large and complex subsea connection systems.”

Investing for the Future

By deliberately positioning itself near its customer’s geographic hubs, Howco can process and deliver its products and services promptly at every location. Currently, the group is making a sizeable investment in its Dubai facility. “At Howco, we regularly invest in our manufacturing facilities across the world to enhance their capabilities,” the pair explain. “This includes significant investments in state-of-the-art CNC machines in our UK manufacturing sites as well as in expanding our Middle Eastern facility. To support the local in-region requirements, we are making a multi-million dollar investment in Dubai to broaden our existing footprint and substantially increase our existing machining capacity. Geared towards increasing our market share in the area, this investment encompasses the introduction of new added value processes, a welfare center for employees, and capacity for further growth.”

Due to its deep involvement in the energy sector, Howco has developed a keen interest in power generation from sustainable sources. In line with that, the company has developed an ambitious Net Zero strategy which will see it achieve carbon neutral status by 2050. Last spring, Howco made a major stride towards this goal by making a significant investment in a solar photovoltaic energy system for its Sheffield and Cumbernauld sites. The solar panels are poised to have a significant impact, with projections confirming that the system will generate 18.3 million kWh of energy over the next 25 years. Not only will the resulting cleaner energy increase the sustainability credentials of both sites by reducing their carbon emissions, but it will also help Howco to offset perpetually increasing energy costs.

Due to its deep involvement in the energy sector, Howco has developed a keen interest in power generation from sustainable sources. In line with that, the company has developed an ambitious Net Zero strategy which will see it achieve carbon neutral status by 2050. Last spring, Howco made a major stride towards this goal by making a significant investment in a solar photovoltaic energy system for its Sheffield and Cumbernauld sites. The solar panels are poised to have a significant impact, with projections confirming that the system will generate 18.3 million kWh of energy over the next 25 years. Not only will the resulting cleaner energy increase the sustainability credentials of both sites by reducing their carbon emissions, but it will also help Howco to offset perpetually increasing energy costs.

Sustainability

Nonetheless, when it comes to sustainability at Howco, this investment is just the tip of the iceberg. Indeed, as Michael outlines, Howco embraces a variety of sustainable solutions and initiatives. “We have set a combined Scope 1 and 2 emissions reduction target of 50 percent for the financial year 2026. By the end of that same financial year, we are also aiming to lower our interim intensity by 50 percent. Moreover, we are aligned with and support the Sumitomo Corporation’s targets of reducing actual emissions by 50 percent by financial year 2035 and to reach Net Zero by 2050. In line with these goals, we have implemented specific action plans, such as participating in local projects reducing power consumption, replacing halogen lighting with LED across all our sites, installing solar panels, as well as investing in energy efficient heating, new compressors, improved compressor pipework, and new boilers where necessary.

“We have also revised our business model to promote a greater concentration on higher value, lower volume materials, thereby minimizing the need for in-house processing. Internally, we have implemented a variety of measures to decrease our impact on the environment. For instance, we are trialing energy reduction schemes for our gas furnaces and are in the process of developing a climate transition plan. Alongside that, we have launched our ‘Take Charge’ energy reduction campaign. As a result of all these efforts, scope 1 and 2 emissions have reduced across the entire group. Currently, approximately ten percent of our energy comes from renewable sources, a figure set to rise further in 2025 thanks to total green energy supply contracts for our facilities in the UK and US.”

Howco is also becoming increasingly involved with Additive Manufacturing. Based in Houston, Texas, this service was launched in 2019, and both the team and its capabilities have grown from strength to strength. Four state-of-the-art machines are now in place and use materials such as 718, Ti6Al4V, 625, 316 and C103. In February 2024, Howco AM’s metal components traveled to the moon as part of the Intuitive Machines IM-1 mission Nova-C class lunar lander!

In conclusion, by continually adapting and evolving to the ever-changing needs of its customers and the markets it operates in, Howco is positioning itself for long-term sustained growth. In the coming years, Jane, Michael, and the Global Directors anticipate significant progress in the drive for green energy, a priority in the business development strategy. To retain Howco’s status as a global leader in the market, it will continue to diversify into other industries and explore opportunities for growth, whether through acquisitions, expansions, or investments in existing facilities.