Howden’s Legacy and Future: Expanding Innovation in Air and Gas Handling

Dealing with the pressure

A portfolio company of KPS Capital Partners since October 2019, Howden has gone from strength to strength, writing yet another chapter in what has been a long history in reliable air and gas handling products

Founded in Scotland, Howden has more than 160 years of strong history and heritage. With its deep roots in technology and innovation, the company is well-established as a world-leading provider of mission-critical air and gas handling products, with more than 6000 employees in 35 countries worldwide, including a core of 750 engineers, and a manufacturing footprint across 30 international locations. Howden has found yet more success, using its profits to fund invaluable operational upgrades, along with its own series of acquisitions to enhance synergies for its customers.

Over the years, we have enhanced our way of working, creating an organization in which the customer is at the heart of everything we do, and one in which operations, quality, and continuous improvement all play together with product development.”

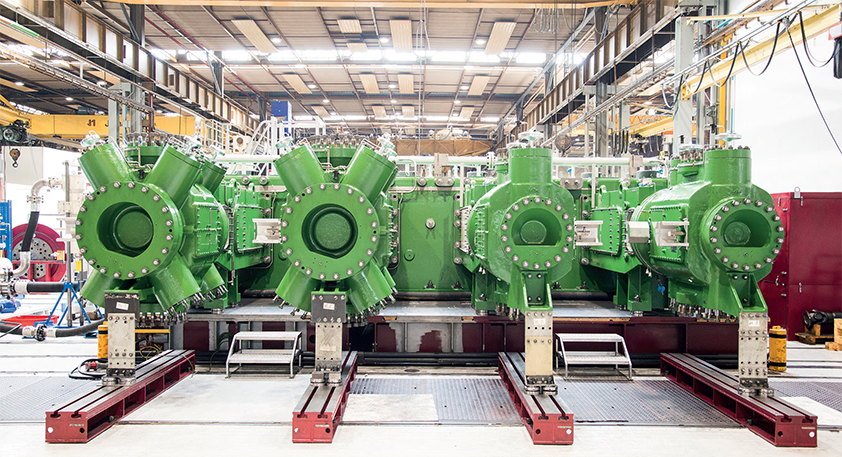

Today, Howden boasts a unique range of more than 20 products across five families: fans, heaters, blowers, compressors, and steam turbines. Although predominately a manufacturer of highly engineered, pre-configured products, the company also offers a strong range of digital solutions. Among them is Howden Uptime, a unique equipment performance monitoring technology. With such a comprehensive offering, Howden delivers a countless number of advantages for its consumers. Nevertheless, there are certain factors that distinguish the company and its products from the competition.

Today, Howden boasts a unique range of more than 20 products across five families: fans, heaters, blowers, compressors, and steam turbines. Although predominately a manufacturer of highly engineered, pre-configured products, the company also offers a strong range of digital solutions. Among them is Howden Uptime, a unique equipment performance monitoring technology. With such a comprehensive offering, Howden delivers a countless number of advantages for its consumers. Nevertheless, there are certain factors that distinguish the company and its products from the competition.

“Efficiency, reliability, and safety are each a core part of our design process,” Massimo comments. “Yet, what sets us apart above all else is our application engineering expertise. At Howden, we have the ability to adapt our products and technology according to the specific needs of our customers, and across a wide spectrum of technical applications and challenges. We operate in traditional markets, including water, chemicals, and steel processing plants, but we also maintain a very strong presence in emerging segments, such as those related to the energy transition, including hydrogen.”

For Howden, that ‘future’ is now. Ever-innovating, the company’s advanced R&D team has a strong pipeline of more than 50 products in development at any given time. “In the last three years in particular, we’ve realized a number of unique products,” Massimo reflects. “Our oil-free screw compressor extended range builds upon the success of one of our well-known product lines, bringing improved capabilities for customers within the petrochemical and energy sectors, as well as within Direct Reduced Iron (DRI) applications. We’ve also employed that same product for an important application on a well-known pilot project for nuclear fusion.”

The mention of nuclear points us towards what is set to be a key challenge for Howden in the coming decades: the inevitable transition towards renewable energy. “On the pure shift away from fossil fuels, Howden is playing very strongly and supporting customers in their transition,” Massimo emphasizes. “The current energy system utilizes a large mix of different fuels, and the trend within the transition is to move away from coal, oil, and progressively, gas. As the cleanest of those three, and because it provides a substantial base-load of energy, it’s widely accepted across the industry that natural gas has a long shelf-life. Howden has some presence in that segment, particularly within liquid natural gas (LNG) and sulfur recovery units (SRU).

“We are also working very actively on hydrogen, across the value chain, with at least a dozen initiatives in that space,” he adds. “By using electrolysis to store electricity, hydrogen can really facilitate the effectiveness of solar and wind energy by reducing the issue of intermittent supply. For over 100 years, Howden has provided hydrogen compression solutions to reduce emissions in the traditional energy industry, and these are now being applied successfully to refueling stations and many other industrial applications. We’re in the process of launching several new products in that space, including a new high-pressure compressor optimized to operate at 1000 bar pressure. We’re constantly working to advance that product range yet further.”

A second area of interest for Howden, and one that the company is making heavy investments in, is the development of carbon capture technology. “We’re working to develop our presence with a rigorous scientific approach, and a holistic view, that will allow us to serve all the major CCSU technologies under development – as they will all require air and gas handling solutions,” Massimo says. “We already have more than a handful of products related to carbon capture and several references; our forte is handling the enormous flow of gas from where the CO2 is contained, and our axial fans are best-in-class from an efficiency stand point. We also have a great solution for rotary adsorption machines and, of course, for CO2 compressors.

“We also have an interesting set of projects orientated around improving the efficiency of steam turbines, a direct and obvious way to reduce Scope 4 emissions, which is now imperative across all industrial processes,” Massimo notes. “We also have new products under development, including a set of solutions targeting heat pumps, a technology that is vital when it comes to electrification, and where we’re able to capitalize on our experience in manufacturing screw compressors for ammonia refrigeration. Our ability to evolve and adapt to these markets is why we have a long-standing heritage, and it’s the reason that we’re so optimistic about our future.”

But for Howden, the products themselves aren’t the end-goal. “Our vision is to enable our customers’ vital processes which advance a more sustainable world,” Massimo reminds us. “In recent years, we’ve dedicated a lot of our resources and efforts towards its implementation. We’ve been working with Shell as part of their response to the EU Renewable Energy Directive (RED II), supplying compressors for what is set to be one of Europe’s largest biofuel facilities in Rotterdam. Likewise, in Chile, we’ve done work with Johnson Matthey, providing green hydrogen compression for the world’s first e-methanol plant. That process begins with CO2 produced by direct-air capture, which is combined with hydrogen derived from renewables to make methanol.

“We’re also very present in the development of green steel,” Massimo points out. “Howden has had a historic role to play with regards to DRI, and we’ve successfully used that technology to reduce CO2 emissions in steel production. Green steel represents the next stage in decarbonizing the steel industry, using large volumes of compressed hydrogen for the reduction process. We’ve already provided compression for the world’s first green steel facility in Sweden, a project called HYBRIT. As one of the highest CO2-emitting industries, steel accounts for roughly seven percent of CO2 emissions globally. Therefore, as demand for it continues to grow, our ability to green that industry is essential if we’re to realize the aims of the energy transition and decarbonization policies.”

As is to be expected from a company at the cutting-edge, Howden’s project portfolio is stacked with a number of similarly world-leading projects. “A particular standout was our work for what is now the largest hydrogen fueling station on Earth, located in China, where we supplied the main hydrogen compressors,” Massimo reflects. “We also delivered the world’s largest hydrogen compression solution at a refinery in the Middle East. To give you a sense of scale, that was an installation with a combined rated compression power of more than 110 MW, installed at a single plant. Our history is full of these interesting projects, and we believe it’s important to continue pursuing them across all our various segments.”

Howden has set about creating yet more history, beginning with a number of acquisitions of its own – including six in 2021 alone. “The last year has been extremely exciting for us in terms of strengthening our operating cycle,” Massimo reveals. “With that comes a stronger cash flow, and then the opportunity to invest that money back into our growth. Of the acquisitions we’ve made, the largest and most recent was for Compressor Products International (CPI), a leading provider of aftermarket components and services to the global reciprocating compressor market. It’s a business that expands our capabilities when it comes to a machine that’s already playing a significant role within the renewables space. As reciprocating compressors are an important part of our hydrogen presence, CPI is a business that adds significant strength to our portfolio.

“Peter Brotherhood is another acquisition that is already improving our capability around energy recovery solutions, enabling us to tackle larger applications in the steam turbine range, now up to 50 MW, offering increased capabilities in Waste-to-Energy (WtE), biomass and other industrial segments,” he continues. “Alternatively, wastewater is a segment we’re very keen on, and in which we have a strong presence, as our installed base in aeration serves the wastewater needs of approximately 750 million people, or ten percent of the global population. Our acquisition of Spencer Turbines offers a way for us to further expand that offering, and to strengthen our position in the US.”

Never short of ambition, Howden has some exciting plans for 2022 and beyond, as it looks to exploit new opportunities within its market verticals. “At the moment, Howden’s installation base is already very significant,” Massimo reveals. “However, there’s always room to grow. We’ve also acquired other after-market service businesses, helping us to further reinforce a model of full lifecycle solutions, and continue to expand our core competencies in our products, our regional presence, and our aftermarket capabilities.”

For Massimo, it all comes down to execution. “Good ideas alone are no longer sufficient,” he insists. “What differentiates great teams is the ability to put those ideas into motion and make them happen to address our customers’ challenges. With our team, and our strategy, we believe we can continue to grow, and to create sustainable and long-term value for our customers and society.”

Howden

www.howden.com

Services: Air and gas handling manufacturing