In the fight against fugitive gas emissions, we must first know our enemy says Mark Naples

Know your enemy’ is a saying that has persisted for thousands of years. The simple reason for that is because it speaks to a truth that has been proven time and time again – you can’t win a fight if you don’t know what you’re up against. That applies as much today, in the fight against global warming, as it ever has throughout history.

Data is our most valuable ally in this fight. Over the last few years, concerted efforts have been made to improve the monitoring of fugitive gas emissions, particularly those caused by the oil and gas sector. The launch of initiatives like the IMEO Methane Alert and Response System (MARS) at last year’s COP28 climate summit, and the increasing use of satellites capable of providing almost real-time quantitative data on emissions, will significantly enhance the level of information available on where emissions are occurring – a vital step in closing a widening gap in our understanding of this problem.

That understanding is essential for combating global heating, a hugely complex issue that hinges on a delicate interplay between a number of different factors. The technology needed to gather the data required to build that understanding is more accessible and accurate than ever – but the oil and gas industry must commit to engaging with it.

A complex global problem

Thankfully, awareness of the threat that fugitive emissions pose and the importance of monitoring them appears to be growing. Carbon dioxide is a well-known GHG that is well-established in sustainability discourse, with terms like ‘carbon footprint’ being widely understood by people across the globe.

Significant commitments are also being made to act on methane by the energy sector and governments alike, as awareness grows of its highly potent global warming potential. Methane traps up to 80 times more heat than carbon dioxide once it is first emitted into the atmosphere, but it also degrades much more quickly. This means that, while it is currently responsible for more than 25 percent of the global warming we experience today, cutting it could have a rapid and significant impact on climate change.

However, this is easier said than done. The accidental nature of most gas leaks, and the fact that most gases are colorless and odorless, renders many almost impossible to detect without a genuine, dedicated attempt to do so – plus bespoke monitoring equipment.

In the oil and gas industry, this difficulty is compounded by the vast scale and complexity of industry operations. The midstream sees gas and oil products transported through pipelines that stretch across hundreds of miles of land, underground, and beneath the sea. Faults in these pipes can emit vast quantities of gas indefinitely, undermining global efforts to cut emissions.

Solutions are within reach

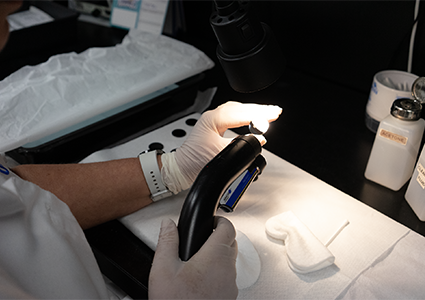

The solution to this global problem requires wide-ranging monitoring operations. This may mean making use of the latest satellite technology, or it may involve on-the-ground equipment that can help businesses begin building their own data on emissions. Leading the way in this field are high-performance infrared sensors, which pass lasers through a filter inside a sampling chamber to measure the attenuation of incoming light and determine the precise concentrations of gas that are present. Changing the filter in this equipment means different wavelengths of light are allowed to reach the detector, enabling it to be used to check for different kinds of gases with remarkable discrimination and sensitivity.

At Umicore, we help OEMs simplify their gas detection systems while helping to drive advancements that let them use their devices in ways they had never previously considered. With more than 35 years’ experience in thin film design and manufacture, we have overseen decades of development of custom infrared designs and other tools for building a clear profile of greenhouse gas emissions.

Technology such as this is helping businesses fill in the picture on methane emissions and better focus their mitigation attempts. Combined with other methods, action on methane by the oil and gas sector today could cut human-caused emissions by as much as 45 percent within ten years. If achieved, this would stop global temperatures from warming by almost 0.3°C by 2045.

This would represent 20 percent of progress towards the target of limiting global temperature rises to 1.5°C and would go a long way to helping achieve targets set out under the Paris Agreement, helping to bring some semblance of stability to an era of geopolitical uncertainty.

As businesses move beyond estimations into a world of empirical measurement, a true revolution in leak mitigation is within reach. Modern technology enables precise tracking of emission changes, providing a greater depth of understanding that will make the oil and gas industry more accountable, help guide regulations, and support companies with their own growth goals.

The fight against climate change is the most challenging fight our planet has ever faced. To overcome the challenges of the future, we can take heed of the words of the past and commit to improving our knowledge of the enemy we face.

For a list of the sources used in this article, please contact the editor.

Mark Naples is Managing Director of Umicore Coating Services, one of the leading manufacturers and suppliers of infrared precision optical filters and coatings to some of the most demanding specifications and applications.

With over 35 years’ experience and more than 2500 proven coating processes, its extensive knowledge enables the business to repeatedly manufacture optical coatings with exceptional spectral and environmental performance.