iNPIPE PRODUCTS: Leading the Pipeline Maintenance Industry with Innovation and Expertise

Pig in a pipe

From its headquarters in Catterick, North Yorkshire, International Pipeline Products Ltd (iNPIPE PRODUCTS) engineers an array of pipeline maintenance and testing equipment.

This comprehensive range includes: foam and metal bodied pigs; inflatable and solid spheres; signallers, launchers and receivers; plugs for low, medium and high pressure environments; flange weld testers and internal weld testers; dual and twin-tyred isolation tools; self-centralising bungs; and further auxiliary products such as hoses and pumps.

The company has been a supplier to major operators and international contractors for over 25 years and continues to grow, with 2009 seeing the highest turnover in its history. Simon Bell, commercial manager for iNPIPE PRODUCTS, puts this success down to the quality of its staff: “We have a long-standing, very loyal workforce; one of the main strengths of the company is the experience within it. There are very few people that actually leave once they’ve joined iNPIPE PRODUCTS, unless they retire.”

This pool of experience means the company is able to work with clients to produce tailor-made products alongside its standard range; bespoke manufacture accounts for approximately 25 per cent of iNPIPE PRODUCTS service. Simon believes that this flexibility gives the company an important edge against competitors: “We pride ourselves in having the experience and expertise to provide a solution, whether it’s a standard product that we’re developing ourselves or it’s a bespoke product with a set of difficult parameters. That’s generally where the expertise comes out, when customers want to do something a little more demanding because of the technical performance required by the operator.”

One such recent client was the National Grid, which approached iNPIPE PRODUCTS with a leaking flowline valve that needed urgent replacement in a live situation. To replace the faulty section of the pipe it was necessary to custom-build a freshly designed isolation tool that would allow for its removal and replacement. Having had previous experience of similar technical faults, iNPIPE PRODUCTS was able to prepare an appropriate solution with speed and efficiency. The isolation tool was designed, manufactured and fully tested within eight weeks; the valve replacement operation itself took 14 hours, and was carried out on behalf of National Grid engineers and under the supervision of Robin Arnold, divisional hire manager for iNPIPE PRODUCTS. This project was a success for the company as ultimately it was completed on time, under budget and to the satisfaction of the client.

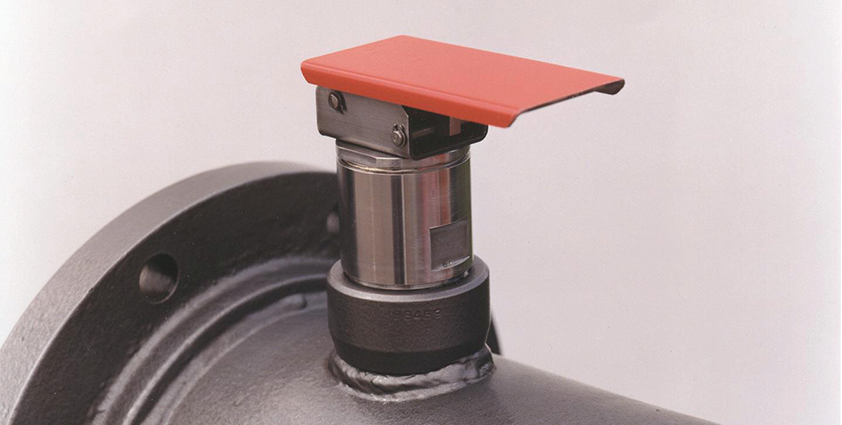

The ISO-approved company has a reputation for designing and patenting innovative products that have become industry standards. The intrusive Pig Signaller, iNPIPE PRODUCTS’ first patent, is one such product. The device was first manufactured in 1986 and has special omni-directional properties. This is of particular convenience when welding because it can be difficult for an operator to know which direction the thread is running. iNPIPE PRODUCTS’ omni-directional pig signaller is able to function at any angle, therefore making it impossible to install at an incorrect position. Simon enthuses about this quality: “I would say one of our strengths is making sure that products are engineered so that there is almost no way you can misuse them.”

The ISO-approved company has a reputation for designing and patenting innovative products that have become industry standards. The intrusive Pig Signaller, iNPIPE PRODUCTS’ first patent, is one such product. The device was first manufactured in 1986 and has special omni-directional properties. This is of particular convenience when welding because it can be difficult for an operator to know which direction the thread is running. iNPIPE PRODUCTS’ omni-directional pig signaller is able to function at any angle, therefore making it impossible to install at an incorrect position. Simon enthuses about this quality: “I would say one of our strengths is making sure that products are engineered so that there is almost no way you can misuse them.”

From its establishment iNPIPE PRODUCTS has been undertaking continuous research and development (R&D) resulting in more than ten patents with further patents pending. Recent R&D innovations have included the Portable Temporary Pig Launcher, designed to overcome space or environmental restrictions in pipelines, the Star Wheel Wax Removal Pig, a cleaning tool specifically for the removal of soft wax deposits, and the special Articulated Pig that has been developed to negotiate long-radius bends. By continuing to invest heavily in R&D the company is able to maintain its foothold at the cutting edge of developing technology.

After receiving an order worth half a million pounds from Egyptian contractor Petrojet in 2009 based upon relationships developed by regional manager Gavin Newall which helped the company achieve the biggest turnover in its history, iNPIPE PRODUCTS is well positioned for even further growth. Simon believes this can largely be attributed to rising awareness of the importance of pigging: “You never consider cleaning something until it’s become dirty or has broken down. Now, though, I think operators are becoming more aware that if you actually look at the long-term aspects you will see not only a payback on your revenues, but you will also ensure your infrastructure lasts much longer.”

In addition to its main products business, iNPIPE PRODUCTS offer other services aimed at providing the best customer service possible. An operator can encounter a wide array of situations and it would be costly to purchase products to deal with all of them. iNPIPE PRODUCTS therefore has a dedicated hiring service named iNPIPE HIRE that is able to provide clients with a more financially suitable maintenance option. One recent contract had iNPIPE HIRE testing pipework on a boat being constructed for the French defence department. This hiring service has available to it the full range of iNPIPE PRODUCTS. Furthermore it runs training programmes to help individuals better understand pipeline pigging, its applications and the industry.

The company also puts forward a focused environmental plan. This begins with an act of community collaboration in which the company will work with students at a local primary school to generate and implement ideas to reduce its carbon footprint. iNPIPE PRODUCTS believes it will aid students learning experience, and sees this as setting a positive example for other companies to follow.

Oil prices are now relatively stable and Simon reflects on how this affects the company’s hopes for the near future: “In the next couple of years I’d like to see us twice the size, consolidating our position and moving the company forward into more service-orientated products and the bespoke side of the industry.”

iNPIPE PRODUCTS

Products: Pipeline maintenance and testing equipment