Intetech Ltd: Pioneering Well Integrity with Advanced Software and Consultancy

Well designed and maintained

Established in 1991, Intetech is a UK-based company that specialises in integrity management, corrosion and materials engineering.

Alongside consultancy and engineering services, the Intetech Well Integrity Toolkit (IWIT) management system software aids oil and gas producers to operate wells more safely and improve operational efficiency.

In 2005 the company formed two subsidiaries: Intetech Wells and Intetech Consultancy. The former is responsible for Intetech’s well integrity work whilst the latter works with clients to prevent integrity problems forming or recurring in surface facilities. Though these two divisions have separate focuses, they also work together to provide a comprehensive and thorough service for all of the company’s clients.

It is the company’s innovative and comprehensive approach which Liane Smith, the company’s managing director, believes has been responsible for its success: “The approach we take really looks at the whole range of issues. We consider every type of integrity problem that could hit a well. Also, our flexibility and the ability to propose innovative solutions to client requirements is why we keep receiving repeat business – people like working with us.”

As Intetech Wells, the company offers a range of different services. One such service is corrosion control; for the Ujung Pangkah project in Indonesia, for example, the company assessed the benefits of alternative tubing materials before advising on product selection and companies that could provide the required materials. Another service the company undertakes is investigations of failures. For a project in Abu Dhabi, Intetech undertook an investigation into the localised failure of carbon-steel tubing in a well. Discovering that the problem was due to souring and the phase behaviour of fluids, the company recommended new materials that would successfully withstand the necessary conditions. Other types of work undertaken by Intetech Wells include management systems and procedures for well operations, lifetime modelling, specialised well design, design of cathodic protection for well-casing, and advice on remedial or preventive work.

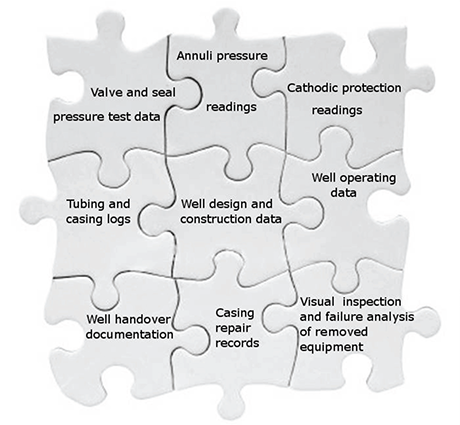

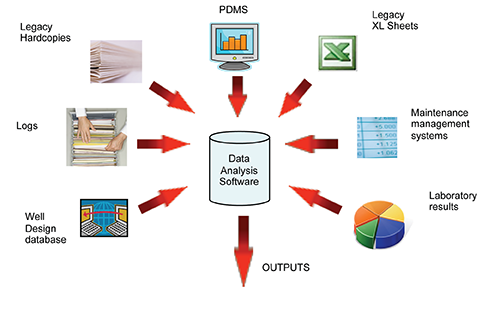

At the heart of the company’s Well Integrity operations is the flagship proprietary analysis software IWIT, developed through years of experience investigating well integrity issues. After encountering problems trying to gather all the correct information during a project, the company decided to develop software that could fully integrate with clients’ database systems and provide all relevant information. It has since developed into a fully-fledged integrity management software that is being used by all types of operators, onshore and offshore, from brand new to mature fields.

Liane details further how IWIT works and the benefits it provides: “The software delivers on three levels. Firstly, it provides a database to users. Companies already have a lot of databases of course, but what IWIT is able to do is interface with those databases so clients with database systems already in place don’t have to throw them away, we can link real-time and use the existing data. It’s very flexible: we’re getting to the stage where we’re almost losing track of the number of different systems that we’ve interfaced to.

Liane details further how IWIT works and the benefits it provides: “The software delivers on three levels. Firstly, it provides a database to users. Companies already have a lot of databases of course, but what IWIT is able to do is interface with those databases so clients with database systems already in place don’t have to throw them away, we can link real-time and use the existing data. It’s very flexible: we’re getting to the stage where we’re almost losing track of the number of different systems that we’ve interfaced to.

“Secondly, it is able to provide real-time analysis of data such as corrosion modelling, annulus pressure correlation or automatic reliability surveys done through statistical analysis of test data from a valves and seals for example. That is what we see as the real added value, the real Intetech contribution.

“Thirdly is the user interface, which is very user-friendly and intuitive. Feedback is given at an engineering level with detailed graphs and tables but also at a management level with pie charts and breakdowns of problematic wells. This meets the needs of management to have a view of the integrity of all of their wells at a glance.”

Intetech has customers worldwide, with 85 per cent of its business being outside the UK. Some of the regions the company operates in include Malaysia, Kazakhstan, Brazil, the Middle East and North Africa. One of its most recent clients is the internationally renowned British oil and gas company BG Group, who installed IWIT for its Kazakhstan operations, and, after seeing its success, commissioned it for wells worldwide. Liane explains further: “We are currently deploying to the UK, Tunisia, Bolivia, Trinidad, Australia and India. It will handle over 1000 wells worldwide but has the potential to grow to 3000 wells.”

When it comes to providing IWIT software, Intetech realises that different clients have different needs. Therefore the system is fully customisable so that each installation can be tailored to tie-in with the customer’s existing practices. This adaptability means that applications as diverse as gas storage wells in Italy and coal-bed methane production in Australia have adopted the software.

Typical projects carried out by Intetech Consultancy illustrate the subsidiary’s focus on high quality engineering consultancy, particularly with regards to corrosion risk evaluation and mitigation. For example, advice was given to Malaysian company Sarawak Shell when it needed to replace risers that had failed during installation. It helped the company with testing procedures that would help avoid similar problems in the future, as well as quality control measures that could be undertaken to ensure a successful re-installation. Intetech was also responsible for investigating the disproportionately high output of mercury in a North Sea oil well. By utilising chemists, engineers, equipment experts, and health and safety advisors, Intetech identified potential leakage points and advised on resistant consultancyreplacement materials so the platform could continue operating safely. Intetech Consultancy also works for other industries, including the wider energy sector, chemical, pharmaceutical and civil engineering firms.

One of the biggest issues facing oil and gas companies is that of facilities near end-of-life. Intetech can potentially provide solutions to the cost of replacing old equipment through assessment of current integrity and prediction of remaining life, together with remedial programmes and mitigation measures that lay out parameters for extending facility lifespan. Integrity and safety are critical however, and equipment not meeting these demands must be clearly identified and dealt with. Intetech is able to prepare necessary plans to help minimise costs and environmental impact.

Intetech Consultancy also provides services for carbon capture and storage (CCS) in which it advises clients of the design and materials for CCS in power plants, carbon dioxide injection wells, and the transportation of high pressure carbon dioxide. This method of controlling greenhouse gases is predicted to become increasingly important in the next few years and, with over 20 years experience in CO2 corrosion, Intetech is well positioned to advise people on the best way to implement CCS techniques.

Over the last year Intetech has seen growth within its own structure, taking on board new employees, opening an office in Asia and expanding its staff. Liane comments: “We have some great ideas for new products and services. Taking on more people over the last year means that we have people we can dedicate to specific product development.”

With the increasing industry focus on well integrity, both within the conventional oil and gas sector and within new applications like gas storage and carbon capture, Intetech is well placed for continuing success into the future.

Intetech Ltd

Products: Well integrity management systems and consultancy