Lilaas AS

Keep control

Lilaas is Norway’s largest, and one the world’s leading manufacturers, of various types of control levers and joysticks. All kinds of vessels, from small fishing boats and ferries, to supply vessels, large tankers and cruise ships are manoeuvred by control levers from Lilaas.

“As a result of unique design, top-grade materials and thorough test procedures, we create products of high quality that require a minimum of service and maintenance. On work or visit, on modern ships all over the world, the probability of seeing our control levers in action is very high,” says Øyvind Lilaas, managing director at the company. “The governing idea has always been quality. As a parallel to this red thread we want to establish a green one. We are convinced that our deliberate attitude may be a contribution to modern environmentally conscious business activities and private consumption. We have technology and skills, and the belief that changes are always possible. Accordingly, in the close future we are releasing a new generation of Lilaas control levers, with a new look and new technology in extended co-function with systems on a higher level.”

After nearly 50 years in business, the company has accrued vast experience. The main markets for its control levers and joysticks are shipbuilders, maritime and offshore-related industries, medicine, defense, and space/satellite related industry when it comes to other precision mechanics. Most of the control levers and joysticks are certified to Det Norske Veritas standards, and Lilaas AS is certified under NS-EN ISO 9001-2008.

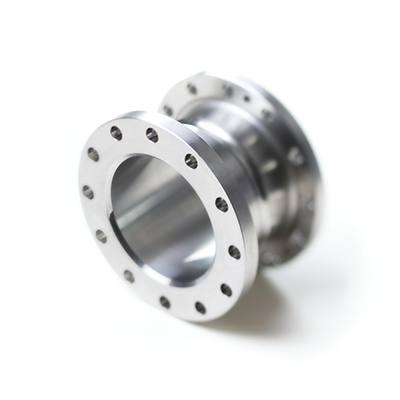

The company has recruited a staff of skilled workers and engineers and created state-of-the-art equipped departments for both mechanical production and manual assembly. The Lilaas factory uses CNC-controlled machine tools with integrated CAD/CAM, while for design and production it uses technology such as Pro/Engineer and EdgeCam, and the Spektra system for materials requirement planning and production control.

The company is a well known creative partner for ideas and problem solving on different fields. It has received a handful of awards for design excellence, both nationally and internationally. It co-operates with demanding customers in the offshore, space, medicine, maritime and general industries, and many well-known companies are on its reference list.

Lilaas AS manufactures small and medium sized details in a range of materials, such as stainless/acid-proof steel, titan, inconel 718, covar, hasteloy, brass, aluminium and various plastic materials.

Lilaas AS manufactures small and medium sized details in a range of materials, such as stainless/acid-proof steel, titan, inconel 718, covar, hasteloy, brass, aluminium and various plastic materials.

The company’s advanced machinery makes it capable to cope with stringent grades of tolerance, a characteristic force of its production. Highly skilled operators operate 15 CNC machines, while a number of multi-task machines work on a 24-7 basis. The highly effective production is based on the company’s own or customer documentation, with general integration between machinery and software. Materials and finishes are closely evaluated based on properties and needs, in co-operation with the customer.

Thanks to cutting edge programmes and 3D printing, Lilaas can also produce prototypes and models of its own brand and customers’ products. These can be finished prototypes or studies of prototypes, complete units, isolated details or parts for larger landscapes. With three-dimensional digital input, the machine builds the model in epoxy-enforced plaster, with or without colour.

Control units are a major contributor to Lilaas’ turnover, and its range includes levers, controlling mechanisms and accompanying electronics. The products range from simple, one-axis control levers in different sizes, hand wheels and rudder controls, to azimuth control units and multi-axis joysticks. All units may be delivered motorised on all axes and with several optional features.

The Azimuth Electronic Shaft System (AESS), developed by Lilaas, can be used in a wide range of applications. Master and slave control levers on different positions on the ship are connected for simultaneous operation. The system is known for its reliability. It’s compact, flexible and ready for future extension.

In addition to its broad standard assortment of control levers, the company offers specialised solutions designed to customer specifications. These specifications are the basis for the development of excellent working co-operation between professional industrial designers and Lilaas engineers. As a result Lilaas has been awarded several times the Norwegian Design Council’s award for Design Excellence, for special products for Rolls-Royce Marine AS. In 2009 it also received the Red Dot award from the international Red dot institute for advanced design studies, for a control panel for Berg Propulsion AB.

Functionality, ergonomics and adaptation to customer profiles are important elements in this development process. Adjustments can be made to existing or new products, according to customer needs and wishes. This is where Lilaas flexibility and experience comes into its own. Its reputation for quality and reliability makes Lilaas AS a natural choice for demanding customers.

Lilaas AS

Products: Control levers and precision mechanics