M-I EPCON AS

Clear opportunities

When oil and gas is produced from a reservoir, it is accompanied by a supplementary amount of water, which increases steadily over the life of a well.

Produced water treatment is one of the main issues affecting operators in the oil and gas industry today, as companies have realised the environmental responsibility, and economic benefits, of managing water levels at installations. As wells around the world enter maturity and continue to produce large amounts of oil, the amount of produced water is increasing at the same rate. This water is contaminated, and must be dealt with before it is reintroduced into ecological conditions such as reinjection to ground reservoirs or discharge to sea or environment.

What is the EPCON CFU Technology?

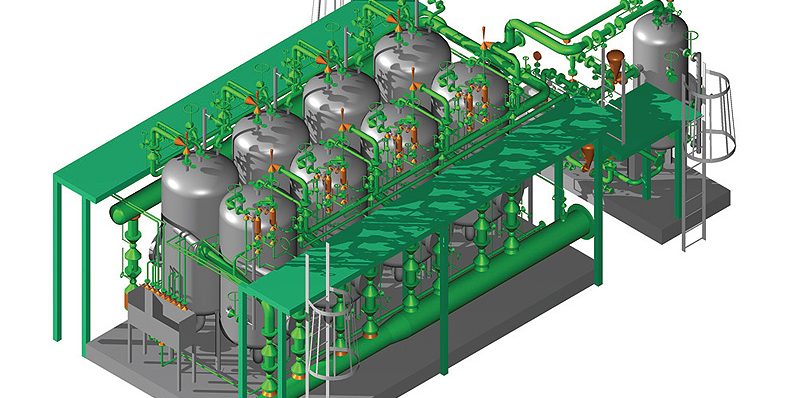

M-I EPCON AS, a fully owned subsidiary of M-I SWACO has pioneered technology used in the treatment of produced water. Compact Flotation Units (CFU) have been created in response to the environmental, operational, and economic issues facing offshore companies – the unit is a vertical pressure vessel that separates water, oil, and gas. Through extensive research at both onshore and  offshore fields, the company has identified seven key applications: as a stand-alone solution alternative to hydrocyclones and degassers; a polishing unit downstream from existing hydrocyclones or flotation units; a downstream separator; dealing with displacement water from storage cells on gravity platforms; acting as a stand-alone solution in the oil side of a degasser; and slop water treatment.

offshore fields, the company has identified seven key applications: as a stand-alone solution alternative to hydrocyclones and degassers; a polishing unit downstream from existing hydrocyclones or flotation units; a downstream separator; dealing with displacement water from storage cells on gravity platforms; acting as a stand-alone solution in the oil side of a degasser; and slop water treatment.

Cost benefits alongside environmental factors

“One of the advantages of the EPCON CFU technology is that it removes some of the soluble damaging hydrocarbons that pollute water – such as benzene, toluene, ethylbenzene, and xylene (BTEX) – alongside the oil dispersed in the produced water,” states Hans Angman, managing director of M-I EPCON AS, who was previously M-I Production Technology’s manager of technological solutions in Europe.

“As regulations become more stringent all over the world, oil and gas operators are turning to us in order to provide technological solutions that deal with these issues. For example, a platform that today deals with water containing 300 parts per million of oil in water and produces 400,000 barrels per day must also focus on oil recovery as well. Equally, operators must be accountable for their pollution levels – or face potential large fines. So there are cost benefits alongside environmental factors that are encouraging clients to use our EPCON CFU Technology.”

Hans continues by explaining how the EPCON CFU is designed to be introduced into an operators process, rather than adapting the process to suit the technology: “The strength of our product is that it is a low footprint, low weight model, and this is important as in many applications there are space limitations, therefore a large piece of equipment is problematic. So there is no need to drastically re-design an installation to introduce our products.

Adaptable to changing circumstances

M-I EPCON is also involved in a range of onshore operations, and this requires less

concentration on saving space. The company is moving into collaboration with many of the major oil and gas operators across the world, on either full scale installation or ongoing testing and evaluation projects.

“M-I EPCON has felt a legitimate ‘pull’ from the market in terms of its technological solutions, and it is important to demonstrate the many application areas the EPCON CFU is capable of operating in,” Hans comments. “In situations when there are difficulties with water and oil mixtures, it is more often linked to the type of application. It is important to show that our equipment is adaptable to these changing circumstances – we don’t build the process to the specifications of our product. This will be a challenge in the future – to continue to deliver the high quality EPCON CFU Technology to a developing range of application areas. It is not a case of simply installing a machine and expecting high performance levels – the process must be researched to understand the differences interacting with the EPCON CFU Technology.”

Must be on our guard

Working alongside many of the major players in the global oil and gas industry, M-I EPCON places the greatest emphasis on research and development in regards to its products. As Hans describes; “As the sector expands we will only be able to continue to supply high quality technology if we are provided with detailed information and research findings. There is one set of information regarding the water before an installation is fully underway, but this will change once the process is fully operational, so we must be on our guard in regards to changing circumstances – as the water’s fingerprint can suddenly become different.

“We have started a project alongside Subsea Systems, dealing with high-pressure water and oil supply, and deep-water environments of over 1000 metres,” Hans states. “This is a significant project for M-I EPCON, as if it is successful, then it will be a big leap forward for the company. We are also involved in a number of ongoing research and development projects at this time.”

Always open to business opportunities

M-I EPCON will continue to work with a number of companies to fully understand the multifaceted applications of its EPCON CFU Technology. Hans remains highly optimistic towards the company’s position in the industry: “The offshore sector looks very promising at this time. Today, M-I EPCON is focused on organic growth, but we are always open to business opportunities that arise – either through technology that is close to, or complementary to our solutions,” he concludes.

M-I EPCON AS

Products: Produced water treatment technology