Master Marine: Innovating Offshore Services with Advanced Jack-Up Vessels

Competitive streak

Master Marine was established in 1997 as an offshore service company, specialising in the transport and installation of heavy structures for the oil and gas industry.

Having been actively involved in the offshore lifting and installation of large modules over the years, the business remains dedicated to maintaining a high level of expertise in all its activities, particularly within the areas of safety, quality and environmental care. During its first ten years in business, Master Marine was principally a management consulting company, operating within  the area of marine transportation and installation services to the major oil companies that make up its customer base.

the area of marine transportation and installation services to the major oil companies that make up its customer base.

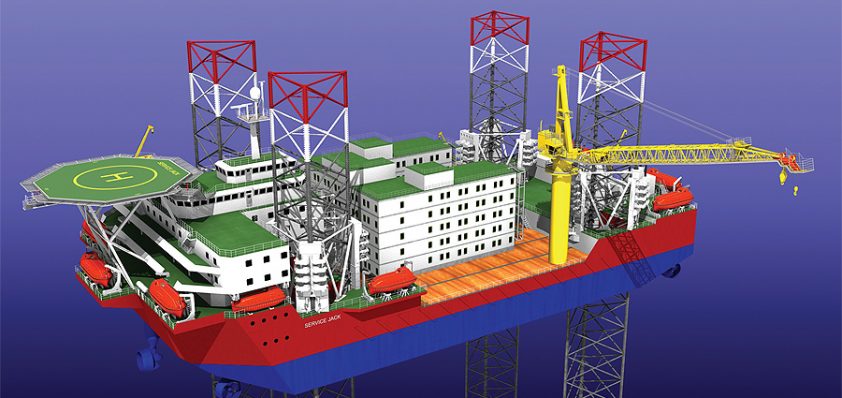

Today, the company delivers jack-up vessels, which provide a safer, more environmentally friendly and cost-effective alternative to other units for the load-out, transportation, offshore installation and hook up of platform structures. Each vessel, designed by Global Maritime, is fully self-contained and able to install offshore structures up to a weight of 7200 tonnes. This means a single unit can replace several barges, tugs, crane vessels and accommodation vessels that would normally be used in offshore field developments.

Thor Stenersen, marketing director at Master Marine, describes the system: “The main strength of the service jack lies in the range of services it can provide. When compared for its individual applications, such as transportation or installation it may not be competitive against other types of vessel, but when the customer sees how many different types of marine activities a single jack-up vessel can carry out, their interest is piqued. The vessel can be used for a variety of applications, including installation, accommodation or construction. This is where our unit is very competitive, especially in terms of safety and environmental protection, as the vessel becomes a fixed structure, which is vastly preferable for the personnel living and working offshore.”

The company currently has two service jack vessels under construction in Indonesia. The first is due to be delivered during the first quarter of 2010 and the second vessel is expected during the third quarter. The first vessel, ‘Service Jack 1,’ has recently been awarded a contract with ConocoPhillips Scandinavia for the Ekofisk renewal project in the North Sea. Thor describes the project: “The vessel for ConocoPhillips was contracted as an accommodation unit at the Ekofisk field. We are currently in the process of modifying the vessel to increase the accommodation capacity from 260 to the 447 that ConocoPhillips requires. Three new accommodation modules will be installed on the main deck. The vessel also includes recreation areas, offices and workshops. The advantage of the jack-up vessel for this project, compared to a floating unit is the comfort and safety of the personnel, which was a priority for ConocoPhillips.”

The second service jack unit will be a construction vessel, able to perform topside and jacket installations by tandem lift, as well as single lift topside installations by skidding. To reduce offshore hook-up time, the service jack can fully handle integrated and commissioned topsides from onshore fabrication sites. This reduces or even eradicates the need for additional support service vessels  during the installation and commissioning phases. Thor comments on the intended function of the new vessel: “As the construction of Service Jack 2 progresses, we are looking increasingly at renewable energy as its area of operation, specifically offshore wind farms in the Danish, German and UK sectors. The UK, for example, is planning a massive expansion of its wind energy programme, and is putting in place some aggressive strategies to achieve this goal. So, there is great potential within the wind power industry; we aim to tap into the renewable market with the new vessel, as the unit’s stability and extreme crane range make it very well suited to this type of application.”

during the installation and commissioning phases. Thor comments on the intended function of the new vessel: “As the construction of Service Jack 2 progresses, we are looking increasingly at renewable energy as its area of operation, specifically offshore wind farms in the Danish, German and UK sectors. The UK, for example, is planning a massive expansion of its wind energy programme, and is putting in place some aggressive strategies to achieve this goal. So, there is great potential within the wind power industry; we aim to tap into the renewable market with the new vessel, as the unit’s stability and extreme crane range make it very well suited to this type of application.”

The company has already made plans for future third and fourth vessels, which will make up part of Master Marine’s future strategy. However, there has been a major challenge facing the vessels’ production. Thor explains: “We are now considering further vessels, but it’s no secret that there is a financial crisis in the world and that it will hit us. We have had to postpone the financing of the new vessels, but we are now picking up the project once again, so we hope that 2009 will give us the opportunity to invest in vessel number three.”

Despite the economic downturn, Thor is confident that there are plenty of future business opportunities in different areas of the industry: “We are now looking to Mexico and the Middle East, in particular the United Arab Emirates, Qatar and Saudi Arabia, which are the three biggest oil producers in the area. These countries have all officially announced that they need to increase their energy demand in order to cope with strategic development that has taken place. To meet this demand they need to either work on building new platforms or significantly upgrade their existing units to increase their production capacity. This will create many new opportunities, which we plan to take advantage of. India is also an area of interest to us as companies operating here are looking to drastically improve their production up time as well as their safety standards. In summary, we see a tremendous interest in our product in these areas and we plan to develop our services to help companies there achieve their goals.”

Explaining the future objectives of Master Marine, Thor concludes: “Our mission is to become the leading company in our market, especially in terms of flexibility and diversity. We want to move with the offshore industry and expand into new areas. If the financial situation improves and economies start to stabilise, then we will be able to achieve our aim of operating between four and six vessels within five years. The market at present is challenging, and although it hasn’t been hampering us directly, we have seen a slowing down with regards to our current work, meaning it will take a bit longer to finish our current projects. However, we know that if our clients trust us to get the job done, we are humble to this challenge but do believe it should not cause a problem. With this in mind, we are also putting a lot of effort into increasing our competitiveness, which means taking into account environmental concerns as well as financial ones. This will allow us to develop the company and ultimately improve our business to provide the best possible service to our clients.”

Master Marine

Services Transport and offshore installation