MENCK GmbH: Pioneers in Offshore Pile Driving and Hydraulic Hammer Technology

Driving force

Beginning operations as a Hamburg based steam and diesel shovel builder in 1868, Johannes MENCK and Dietrich Hambrock founded MENCK & Hambrock. The company has since developed its services and honed its expertise in the production, rental and sale of pile driving hammers to become the major global player in the oil and gas industry operating as MENCK GmbH. With work beginning in a humble backyard, the two men developed the first steam-powered mobile vertically standing boiler unit, which was then used for a piling rig in 1871. This semi-automated piling rig was the first to be brought to market and by means of generating the energy to drive piles, it uses the same principles still applied by MENCK GmbH today.

Discussing the company’s developments over the last century, Fabian Hippe, Managing Director of MENCK GmbH told Energy, Oil & Gas magazine in October 2015: “Excavating machines were MENCK’s core business well into the mid 1900s, when in 1937 MENCK’s products consisted of excavator machines along with steam and diesel driven piling hammers and piling rigs. Since then piling systems have become our main service offering, and it has helped that this business segment has been part of MENCK since day one as we have gained revenue and a strong reputation from this.” Today an expert in the specialist field of offshore pile driving, MENCK GmbH uses its superior knowledge to deliver high quality, reliable products to customers within the oil and gas industry, renewable energy and civil and bridge sectors. Discussing the reasons behind the company’s success in challenging environments and demanding markets, Fabian says: “A major strength is our capability in using our hammers in any environment. They are primarily used above water but can be submerged to water depths of up to 3000 metres; we are the only company in the world that can drive piles in deep water. The deepest we have reached is 2250 metres at BP’s Block 31 development in Offshore West Africa.”

Discussing the company’s developments over the last century, Fabian Hippe, Managing Director of MENCK GmbH told Energy, Oil & Gas magazine in October 2015: “Excavating machines were MENCK’s core business well into the mid 1900s, when in 1937 MENCK’s products consisted of excavator machines along with steam and diesel driven piling hammers and piling rigs. Since then piling systems have become our main service offering, and it has helped that this business segment has been part of MENCK since day one as we have gained revenue and a strong reputation from this.” Today an expert in the specialist field of offshore pile driving, MENCK GmbH uses its superior knowledge to deliver high quality, reliable products to customers within the oil and gas industry, renewable energy and civil and bridge sectors. Discussing the reasons behind the company’s success in challenging environments and demanding markets, Fabian says: “A major strength is our capability in using our hammers in any environment. They are primarily used above water but can be submerged to water depths of up to 3000 metres; we are the only company in the world that can drive piles in deep water. The deepest we have reached is 2250 metres at BP’s Block 31 development in Offshore West Africa.”

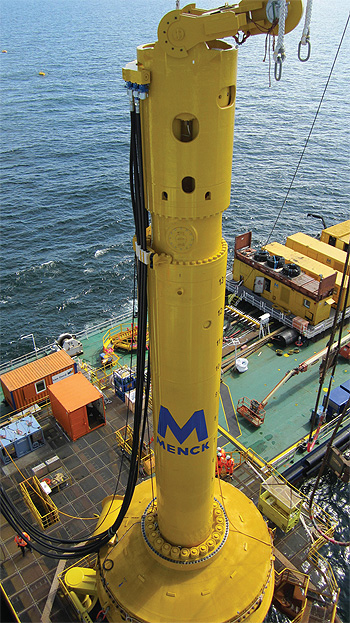

For customers seeking pile driving systems with hydraulic hammers, MENCK GmbH has a product portfolio ranging from 100 kJ to 3500 kJ, the latter of which is by far the largest in MENCK’s product portfolio. Standing at around 21 metres above ground in the vertical position and known as the ‘Gentle Giant’, the MENCK MHU 3500S’s hydraulic hammer exerts a massive 6.0 kJ per tonne of weight, with a pile sleeve that has a diameter of 6.5 m. Weighing approximately 580 tonnes in air, it has a proven highest energy-to-weight ratio if compared to any other hammer in the world, but is also two to three db quieter than other hammers within MENCK’s portfolio. This ensures the MENCK MHU 3500S contributes to all environmental protection requirements.

Elaborating on the development of this milestone in pile driving history, Fabian comments: “In 2014 there was a change in the renewable energy market to extra-large diameter piles, which involved harsh regulatory requirements to maintain a certain noise levels. This noise level was becoming mandatory in Germany and a maximum piling time was implemented and mandatory by then too. Both of these factors contributed to the need for a new approach in piling, to support the noise reduction as well the piling time.

“Our approach was to oversize the system for the undertaking you do, which means it wasn’t a requirement to run the hammer at maximum energy and in turn supports a lower noise profile. This still delivered sufficient contingency in terms of energy to maintain the installation time regulation.”

He continues: “In 2014 we successfully supplied the first MHU 3500S hydraulic hammer to assist Bilfinger Marine & Offshore Systems with the installation of monopile foundations for Vattenfall’s Project Sandbank, a new 72 strong turbine wind farm located in the North Sea.” Following this successful project, the company has focused on building a second unit, which in turn is fully contracted along with the first one throughout 2016 and 2017.

Complementing the company’s commitment to supporting the client in any direction that the operational phase may take it is its solid history for innovation and strong heritage. Furthermore,  MENCK GmbH is also part of the ACTEON Group of Companies, which acquired the company in 2003. “Being part of ACTEON enables us to collaborate with sister companies to provide integrated services in all industries. This way of working has proven particularly beneficial in the growing renewables sector; an area in which we have invested heavily over the last two years to ensure we can supply the right size hammer combined with mature services,” says Fabian. “Our collaborations have given us an edge in the market through the development of intriguing business propositions that are becoming increasingly recognised by companies. For example, by being flexible we can provide the contractor with a wholly integrated package or play a key role in part of the project. This enables us to deliver the best possible solution for the client and the industry where we are operating.”

MENCK GmbH is also part of the ACTEON Group of Companies, which acquired the company in 2003. “Being part of ACTEON enables us to collaborate with sister companies to provide integrated services in all industries. This way of working has proven particularly beneficial in the growing renewables sector; an area in which we have invested heavily over the last two years to ensure we can supply the right size hammer combined with mature services,” says Fabian. “Our collaborations have given us an edge in the market through the development of intriguing business propositions that are becoming increasingly recognised by companies. For example, by being flexible we can provide the contractor with a wholly integrated package or play a key role in part of the project. This enables us to deliver the best possible solution for the client and the industry where we are operating.”

One example of this collaborative approach is the company’s current project alongside sister companies LDD and UTEC. This is to deliver a total foundation solution, including a subsea pre-piling template (PPT) to Offshore Windforce WIK (OWF) – a joint venture between Boskalis and Volker Stevin International. LDD’s PPT is being used to pre-install foundation piles into the seabed in advance of the placement and grouting of the four-legged jacket foundation structures off the Giant 7, a Boskalis vessel. This total pre-piling package offers both commercial and operational benefits in terms of productivity and the merging of complementary expertise, which has thus resulted in a first-class, cost effective solution for a challenging project. “Through fully integrated group collaboration, we can deliver to the market a streamlined approach that is commercially interesting and technically viable. We can also provide solutions to the challenges that we see today. When it comes to cost reductions for the operator, we can integrate crew and equipment on a significant scale,” concludes Fabian.

Although the oil and gas market remains challenging for those operating in it, MENCK GmbH has come up with a new way of operating that benefits customers, as well as ensuring continued demand for services that have been strengthened through working alongside its sister companies.

MENCK GmbH

Services: Global pile driving services