Naxys AS

Subsea detectives

One of the most important issues faced during the lifetime of any offshore mining project is the safety and security of oil and gas processors.

Exposed to subsea pressures and extreme environmental conditions, structure integrity comes under a lot of stress; even when a critical event does occur it may not even be noticed for hours or days. This is bad news not just for the operator in terms of asset loss, but also for the local environment because of unnecessary pollution.

Consequently, leak detection systems (LDS) have risen to popularity. Whilst they do not necessarily prevent leaks from happening, they are essential in minimising leak amounts. Since 2001, Norwegian company Naxys AS has been producing detection equipment that deals with such problems directly. There are a number of different monitoring technologies available, including vapour-sensing tubes and infrared radiometers, but Naxys’ preferred method is acoustic detection.

Managing director Jens Abrahamsen explains how the company’s detectors work: “Rather than having lots of cables all over the pipe or structure, one acoustic sensor is placed on each object of interest. By placing them at the centre of the installation, the sensors are able to pick up through the water all the sounds generated by the structure then identify the source of the sound. This developed from the work of my colleagues and I for a defence sector company named Geco Defence, where we made sonic survival systems for submarines.”

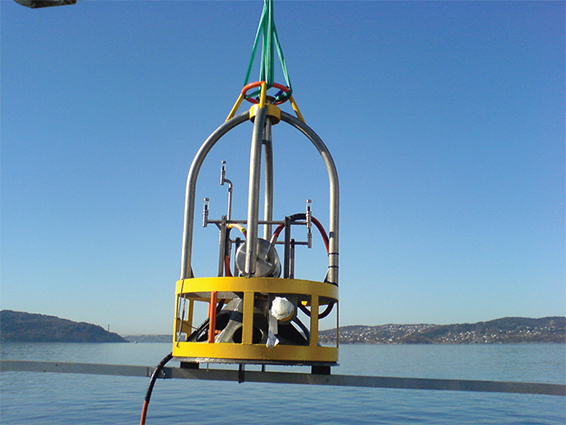

Naxys produces a number of different components and systems but core to its range is the acoustic leak detector (ALD), also known as the Cage due to its resemblance to a birdcage. It is a metre wide, 1.8-metre tall titanium unit fitted with either five or 22 hydrophones placed, as Jens described, at key locations on a subsea structure. This array of acoustic sensors gives the ALD two key advantages in addition to leak detection. The first is that it is able, through data processing and analysis, to eliminate ambient sounds such as vessel thrusters, therefore making alerts more accurate; the second is that, with an array of hydrophones, it is able to pinpoint the location of the rupture.

“The Cage does more than just leak detection,” adds Jens. “The 22-hydrophone model is known as the acoustic leak and vibration detector (ALVD) and is also able to carry out condition monitoring. This means that the system picks up acoustic fingerprints from the pumps, compressors and other equipment of a subsea well, and this can then be analysed to see if it is working properly. If there is damage developing on a pump, for instance, then the vibration levels will increase and this can be indentified long before it actually breaks down.”

However, it is not always necessary to have the ALD or ALVD. In conjunction with Aker Solutions, Naxys has thus produced the single acoustic leak detector (SALD) for use by ENI in the Goliat Fields. Functioning purely as a leak detector, the SALD has a single sensor and an effective detection radius of eight metres meaning that although it cannot pinpoint direction, a small size makes it both cost effective and easy to install. For large areas such as the Goliat Fields, a wide spread of SALDs makes more economic and logistical sense than Cages that are few and far between.

However, it is not always necessary to have the ALD or ALVD. In conjunction with Aker Solutions, Naxys has thus produced the single acoustic leak detector (SALD) for use by ENI in the Goliat Fields. Functioning purely as a leak detector, the SALD has a single sensor and an effective detection radius of eight metres meaning that although it cannot pinpoint direction, a small size makes it both cost effective and easy to install. For large areas such as the Goliat Fields, a wide spread of SALDs makes more economic and logistical sense than Cages that are few and far between.

In-depth research and development into products is a crucial element of Naxys’ business. With a team led by numerous PHD level engineers, the company undertakes an ongoing programme of development on both new and existing products, with the aim of making more accurate sensors to increase safety capabilities. Because of its location in Bergen on Norway’s east coast, where local waters reach great depths very quickly, the company has been able to construct a test bed for its R&D. Located 300 metres from Naxys’ offices, just outside its quay facilities, a system has been built 210 metres below the surface to simulate different leaks and test how current and new systems can be improved. Further supporting this, the company engages in R&D together with the University of Bergen and the University of Southampton.

For all the advantages a Naxys product has however, it can be difficult to market a product that does not provide immediate results. Even in the mature North Sea market, despite the potential savings they offer LDS are more rare than common because it does not directly boost financial turnover. Nonetheless, this pattern appears to be changing, particularly following the Deepwater Horizon incident.

“The market on the Norwegian continental shelf has been about having the very best hydrocarbon leak detection systems, and this has been driven by Statoil,” Jens explains. “However, what we see now are others following suit – ENI now introducing LDS to Goliat Fields, for example. We also recently delivered our first system to a non-European country, to the Pazflor Field in Angola for operator Total. What happened in the Gulf of Mexico is an example of how important it is to have good LDS so hopefully what this means is increasing interest on the global market for such equipment.”

He goes on to conclude that the future for Naxys and detection systems in general has plenty of scope for development: “Over the next four to five years I would like to see LDS on all new subsea installations, and hope to see them installed on structures that are already on the seabed. This is already happening in Norway and gradually this will, I hope, expand beyond this country. As this occurs Naxys will be there, developing with the market and improving our products.”

Naxys AS

Products: Subsea leak detection systems