NKT Flexibles I/S

The flexible approach

NKT Flexibles is a supplier of flexible pipe systems to the offshore oil and gas industry, as well as the chemical and water industries, worldwide.

The flexible pipe systems are highly engineered and provide a complete solution to the company’s clients, which include oil companies and organisations within the contracting industry.

Michael C. Hjorth, CEO of NKT Flexibles, outlines the history of the business: “NKT was originally established as a cable manufacturer in 1898 in Denmark. NKT Flexibles has grown out of this  company and was established as an independent business in 1999 with its headquarters in Copenhagen, Denmark, and its main manufacturing facility located in the town of Kalundborg. We’ve been delivering our systems to the pipeline industry for over 40 years and to the oil and gas industry for the last 12 to 13 years. Today we’re a worldwide provider of flexible pipe systems to all the major oil and gas companies involved in the offshore sector.”

company and was established as an independent business in 1999 with its headquarters in Copenhagen, Denmark, and its main manufacturing facility located in the town of Kalundborg. We’ve been delivering our systems to the pipeline industry for over 40 years and to the oil and gas industry for the last 12 to 13 years. Today we’re a worldwide provider of flexible pipe systems to all the major oil and gas companies involved in the offshore sector.”

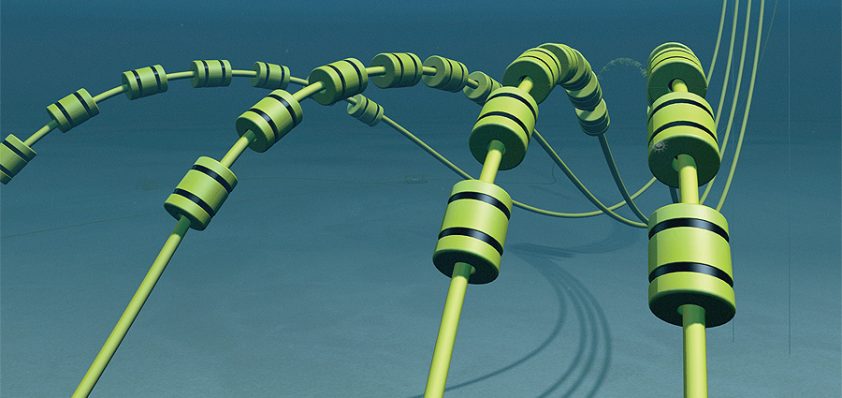

The flexible pipes produced by NKT Flexibles are used for versatile offshore oil and gas applications, such as production, gas lift, gas injection, water injection and ancillary lines. The flexible pipe is an unbonded structure consisting of helically wound metallic armour wires or tapes combined with concentric layers of polymers, textiles, fabric strips and lubricants. The pipes combine the flexibility of a polymer pipe with the strength and durability of a steel pipe. The pipe systems can be installed without divers, making load-out and installation much safer as well as faster and cheaper than any other pipe application. NKT Flexibles’ systems can also be retrieved and reused for alternative applications, this enhances the overall field development economics and helps to preserve the environment.

Each pipe is a purpose-designed product, which is optimised for each specific application. Michael elaborates: “The pipes are developed, engineered and manufactured specifically to the project. It is the particular project’s requirements that define parameters such as the size, length and pressure capabilities of the pipes. It means that we have to start from scratch each time and develop the system from a design point of view before we can procure the necessary materials, and then manufacture and test the product before delivering it to the client.”

Supporting the highly engineered pipe technology is NKT Flexibles’ advanced research and development department. This focuses on developing escalating technologies that will allow the company to carve out niches in the industries it serves. Michael comments: “Our success is based on our advanced skills in terms of process and materials technology. We also offer additional services – not just the pipe product itself but also the entire systems, which means all the accessory components that work with the flexible pipe system. Our R&D department employs some 40 people and we invest a substantial amount of our annual turnover back into its work. Incorporated within the department, we also have a world class facility for sour service testing in addition to a state of the art laboratory facility.”

The company also monitors the market to identify niches; one such niche was discovered in the area of ultra deepwater field developments. NKT Flexibles has developed its own solution for these kinds of projects, called the Flextreme. It is a hybrid composite/metallic unbonded flexible pipe, which can withstand the water pressure at depths beyond 2500 metres. It has a low weight and extremely high crushing, collapse and tensile capacities. The concept allows for the implementation of carbon fibre-reinforced polymer (CFRP) materials in the flexible pipes, which effectively push the envelope of composite pipes towards water depths that could not be reached using conventional flexible pipe technology. Michael comments: “Flextreme is our proposal to the industry for depths greater than 2500 metres. The standard flexible pipe products cannot reach these depths because the steel components are not strong enough to carry their own weight in such water depths. In order to produce a pipe system that can cope in ultra deepwater, we had to change our design concept and the materials used. The Flextreme is our bid for a composite pipe structure for the future.”

Another development came earlier in 2008, when the company experienced a breakthrough in the Brazilian market, when it entered into a three-year frame agreement with Petrobras. Michael explains: “The agreement covers the delivery of 90 kilometres of pipe for installation at water depths of up to 2000 metres. The project will run from 2009 to 2011 with a value in the range of 275 million US dollars. We already operate in the North Sea, Gulf of Mexico, South America, West Africa, Mediterranean, Middle East, India, the Far East and Australia so this sees a new market opening up for us and we are exceptionally pleased to be awarded the frame agreement by Petrobras. It confirms our strong position in the global market for offshore flexible pipe systems and supports our long-term development program. Furthermore, this project marks the entrance of NKT Flexibles into the hugely important Brazilian market, which accounts for some 50 per cent of the global flexible pipe market.”

The business has responded to this progression with the announcement of plans to expand its factory in Denmark, adding another 65 per cent production capacity. Michael comments: “It’s a natural reaction to the market requirements and to expected future growth. It’s very important in this industry that we show the customers that there will be sufficient capacity in the future, so they know that they will be able to source the solutions and the products they require in order to meet their own growth plans.”

NKT Flexibles is also looking to make other advancements to the business in the future. Michael outlines the areas he wants to improve: “We would like to strengthen our market position on the technology side; we want to be the number one solutions provider in the areas that we focus on. Our other goal is to work on bringing the Flextreme to the market as a technical solution that we believe is the best ultra deepwater pipe system in the industry.” Michael is also confident that there will be an abundance of opportunities within the industry in the future: “We are a subsea focused company and we are seeing a definite trend in the extraction of offshore oil and gas resources; particularly in terms of floating production and subsea solutions. This is a great thing for us as it means that there will be a growing demand for our solutions in the future.”

NKT Flexibles I/S

Services Flexible pipe systems