Northey Technologies

Recovering markets

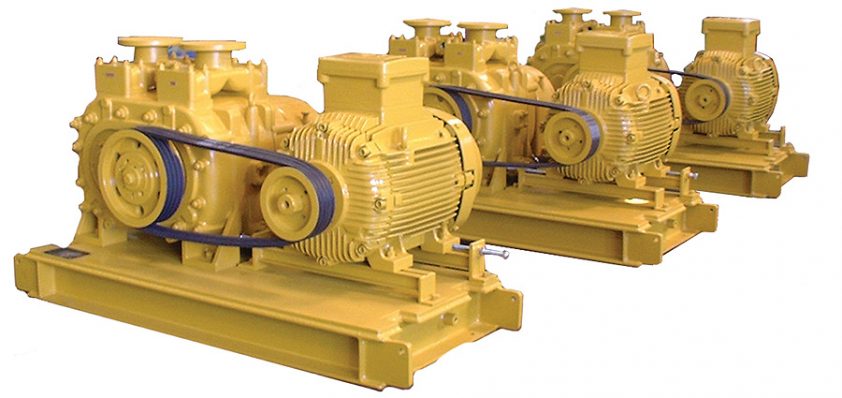

With a history of excellence dating back to the invention of the rotary internal combustion engine by Mr Northey in the 1930s, Northey Technologies has evolved and developed over the years to produce a number of leading vent and flare gas recovery solutions, vacuum pumps and compressors, as well as waste handling process applications.

Originally Mr Northey’s combustion engine failed to find success in the British motor industry but was found to be an ideal supercharger for other applications. After the Second World War the company merged with another to create Northey Boyce, specialising in compressors and vacuum pumps, which in turn lead to the foundation of Northey Rotary Compressors, a business that based  its expertise on dry, oil-free machines.

its expertise on dry, oil-free machines.

The organisation went from strength-tostrength, gaining a number of lucrative contracts with principal names in the railway industry for the supply of vacuum pumps, which lead it into the export market and the supply to over 27 countries. Such a varied background has resulted in Northey Technologies’ market leading flexibility and bespoke offering in the oil and gas, water and waste treatment industries. It is now a distinguished global company with the majority of its turnover being export based to regions such as Singapore, China, Australia and mainland Europe, with a focus on Holland.

“Currently, our main market is oil and gas, with gas processing applications being our main offering,” Bernard Whicher, managing director of Northey Technologies, explains. “Another very topical and ever-evolving area for us is in the water industry with the waste handling of biogas and emissions. We’ve developed a number of machines to deal with the process known as anaerobic digestion, which generates power from waste by producing methane, otherwise known as biogas.

“We were at the forefront of the development of this method and our machines are used throughout the digestion process to circulate and pressurise the methane ready for generating power. We supply and produce gas and air compressors, root blowers, side channel blowers and boosters, as well as gas holders to serve this industry and are growing in the landfill market.”

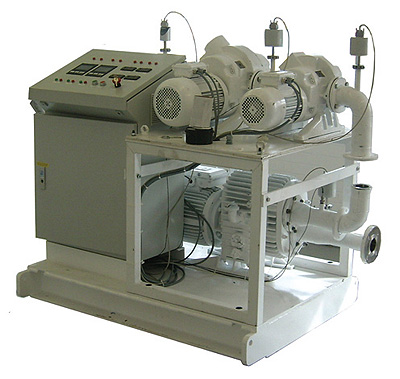

The company has recently developed a vent gas recovery system (VGRS) for use primarily on offshore platforms, though it can be adapted for any application where gas is flared or vented into the environment. It is designed to recover vapours such as natural gas, BTEX, water and inerts (nitrogen, carbon dioxide) from TEG (tri ethylene glycol) boilers and distillers, which cannot be discharged into the environment under current legislation.

The vapour is extracted via an existing LP vent line, which is continuously drained to a holding tank due to the fact that it collects condensed liquids and prevents liquid entrainment. To remove the condensates, the gas is compressed, then cooled using a shell and tube after-cooler, and cooled further by a refrigerated chiller system, while droplets are removed in a separator. The processed gas is then reheated using the incoming gas to prevent any further condensation on the process line – a lengthy but essential process to ensure that operators are in line with environmental legislation.  Northey Technologies has already delivered five bespoke packages for this application to platforms in the North Sea.

Northey Technologies has already delivered five bespoke packages for this application to platforms in the North Sea.

Research and development is a mainstay of the company’s efforts in the field, with its existing products being continuously updated and improved to meet the changing needs of its customers and the market. Two new projects are being successfully carried out in Australia in the biogas field to replace competitive technologies currently using liquid ring and oil lubricated sliding vane machines.

Northey has supplied seal-less machines using canned motors and magnetic couplings and has recently patented a leak free machine to help Northey Technologies Ltd remain at the cutting edge of industry.

Bernard outlines the key factors that set the company apart from its competitors: “We’re extremely flexible, innovative and we specialise in bespoke packages. We only create oil-free, dry solutions so there is no consumption of oil or consumables, very low maintenance requirements, and we provide a committed service throughout. We have a long history of invention and an innovative approach to conventional problems. We have a patented technology for use with toxic or dangerous gases and produce a specialist pump for the nuclear industry, which handles radio active gases as part of uranium enrichment and has been highly successful in the Chinese market.”

Despite the global recession that has affected a number of industries and market sectors worldwide, Northey Technologies has escaped unscathed. The high price of oil has aided the company, while the increasing awareness of carbon emissions and energy from waste technology has brought Northey technologies’ applications firmly into view. However, it seems the company is on a different cycle of success to other industries and so is preparing for possible impact in the future. “We’re strong at the moment and continuing to grow, but we don’t know how long it will last. Our main aim is to continue to innovate and introduce new solutions to the market in order to have a big impact in the energy from waste area,” Bernard concludes.

Northey Technologies

Services: Vent and flame gas recovery