NOV Brandt Product Sales

Controlled growth

Operating as part of National Oilwell Varco (NOV), NOV Brandt Product Sales is a global provider of mechanical solids control equipment, used to remove detrimental solids from the mud system when drilling for oil.

These products are provided as part of the complete package that NOV can offer to its customers, and they are used in one of the most important phases in the drilling process.

Amongst the products offered by NOV Brandt Product Sales is the gumbo removal equipment range. The gumbo chain is positioned before the mud gas separator at the flow line, and it consists of a simple device that uses a flat, chain-type conveyor for removing large, sticky clays (gumbo) and other troublesome solids from the mud system. The chain opening size on these units can vary depending on the formation drilled and the needs of the drilling operation.

Mud gas separators also comprise an important part of the NOV Brandt Product Sales portfolio. These products are used to mechanically remove entrained gasses such as hydrogen sulphide, carbon dioxide and natural gas from the mud system, as these can reduce the hydrostatic head of the mud column and can cause catastrophic well control problems. Because such separators are one of the first units of solid control equipment arranged to treat mud, these mud gas separators are able to process all of the mud from the flowline before the mud reaches the primary shale shakers.

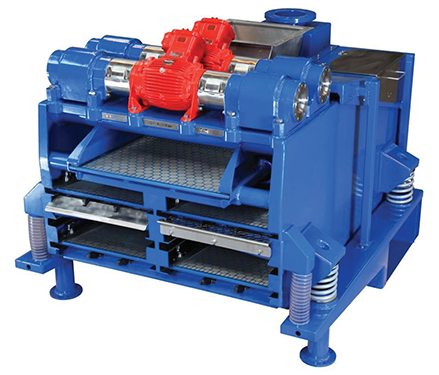

Shale shakers are also provided by NOV Brandt Product Sales and these are used to separate solids from liquids by using a vibrating basket outfitted with specially designed screens. Perhaps considered the most important tool for removing drilled solids, these units are responsible for removing the majority of drilled solids that are generated during the typical drilling process.

Included within this range is NOV Brandt King Cobra, which utilises four pretension screens and linear motion to remove any detrimental drilled solids from the mud system. Operating in this way means that the NOV Brandt King Cobra can minimise mud losses whilst still enhancing cutting dryness. Furthermore, maintenance on the NOV Brandt King Cobra is minimal and only a small inventory of replacement parts is necessary to sustain optimal operation. The shaker’s rugged design also offers years of reliable operation.

With the success of the NOV Brandt King Cobra, a modified version was more recently created, labelled the NOV Brandt King Cobra Venom. This new product was developed through the feedback of NOV customers, and it employs many of the field-proven technologies of the previous NOV Brandt King Cobra shaker line while utilising new technologies, designs and options as well.

With the success of the NOV Brandt King Cobra, a modified version was more recently created, labelled the NOV Brandt King Cobra Venom. This new product was developed through the feedback of NOV customers, and it employs many of the field-proven technologies of the previous NOV Brandt King Cobra shaker line while utilising new technologies, designs and options as well.

The NOV Brandt King Cobra Venom benefits from reduced dimensions and a lower weight, and so is able to be installed on a wider range of rigs on the market. With a new modular design and standardised platform, customers are given the opportunity to upgrade the product to meet their specific needs, regardless of how the shaker was originally configured at the factory. This field-upgradeability provides the user with a great deal of flexibility in situations of constantly changing needs.

NOV Brandt Product Sales is also renowned for its mud conditioners, which were originally designed to remove fine drilled solids from weighted mud without the excessive loss of barite and fluid. This use evolved and now their primary purpose is to de-sand weighted mud and to reclaim the liquid from the hydrocyclone during the unweighted hole section.

NOV Brandt Product Sales manufactures both negative pressure (vacuum) and atmospheric degassers. Vacuum degassers are designed to utilise negative pressure to withdraw entrained gases from the mud. Here, the mud is pumped through a venturi, where it develops a negative pressure, and sucks the mud into the main unit. This mud then flows over horizontally or vertically arranged dispersion plates, creating thin sheets of gas-cut mud. These plates can then bring the entrained gases closer to the surface for easy removal.

The atmospheric degassers are considerably less complex in their design and operation. These units simply remove the gas through mechanical means, pumping mud into a thin layer in order to allow the gas to liberate itself.

NOV Brandt Product Sales also offers horizontally mounted agitators as part of its product portfolio, and these have been used as the industry standard for many years. Due to its rugged design, simplicity and dependability, these products have gradually become the preferred choice for the vast majority of operators and contractors.

The low profile of these agitators reduces headroom requirements, and their quiet, vibration-free operation makes them a popular choice. Available from three to 30 horsepower, the NOV Brandt MA series uses a sliding action worm and gear, whereas the NOV Brandt MA-RG series is a double-reduction helical gear designed primarily for applications that require more than 15 horsepower.

NOV Brandt Product Sales offers vertical agitators through its VMA series as well, and these are ideal for installations with limited footprint availability. These double-reduction, in-line, helical gear agitators allow for smooth, vibration-free operation and efficient mixing. They also align the motor shaft with the gear reducer output shaft. Furthermore, the explosion-proof, C-face motor bolts onto the double reduction gearbox for improved efficiency.

In addition to all the other products of NOV Brandt Product Sales are the HS-3400 and HS-2172 centrifuges, which are used to process weighted and unweighted water-based or oil-based drilling fluids. By using mechanical energy to increase the gravitational force exerted on solids that are present in the mud system, these centrifuges are able to apply more than 3000 G-forces on the mixture. This separates the heavier solids from the lighter solids, ensuring that the proper mud weight and viscosity is maintained.

With such a wide product portfolio, and thanks to the financial support provided through National Oilwell Varco, NOV Brandt Product Sales is in a strong position in the solids control equipment market. By working with its customers to acquire feedback on its products and service, the company will continue to develop its offerings and, as a result, will further strengthen its foothold in the global market.

NOV Brandt Product Sales

Products: Solid control equipment