OTS Offshore and Trawl Supply

Strong connections

OTS Offshore and Trawl Supply is a Norwegian manufacturer of synthetic fibre ropes that offer extreme strength up to 2000 tonnes, providing products for operational installations in the oil and offshore market.

Its production, design and engineering are based on high-tech fibre ropes and combined products such as thimbles, shackles, chains and buoys. Its range of fibre ropes includes dyneema, polyester, twaron and nylon.

The OTS factory, situated near Aalesund in Norway, is one of the most modern in Europe and is fitted with the latest production line, capable of obtaining the best from high-tech fibres and producing ropes up to 350 mm diameter. After nearly two decades in operation, OTS is enjoying the benefits of expanding its manufacturing capacity as the demand for its products continues to grow. Assistant manager Jan Lunde outlines the company and its activities: “We operate in maritime sectors where seismic, offshore, fishery and towing are the main fields, delivering tailor-made products to customers. The business was established in 1990, when we sold products made by other rope manufacturers, and in 1996 we commenced our own production so we’ve been producing our synthetic fibre ropes in-house ever since. In 2007 we doubled our production capacity by investing in new facilities and manufacturing machinery so now we’re fit to meet the increased demand for synthetic fibre ropes.”

OTS delivers well-tested products and works in close collaboration on its various projects with customers to produce ropes to certain specifications. “Our main strength, beside our competent product, is the fact we discuss solutions with our customers to develop products together,” asserts Jan. “This is why the end result is perfectly suited to do the job that the client requires. Being small and flexible is important to our success – we have a very accommodating staff.”

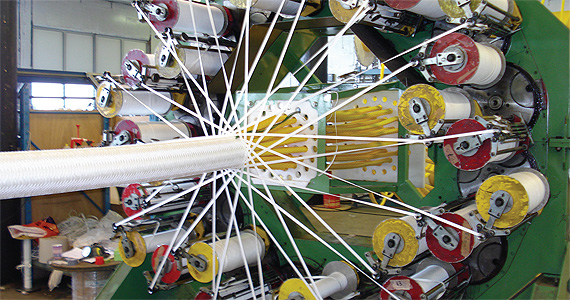

Another of OTS’ strong points is its unique offering in the form if its OTS protective jacket for the rope it produces, which provides excellent resistance against wear and tear. It also simplifies inspection of the rope and helps to protect against sand intruding into the rope. Jan explains: “We braid the protective jacket into the rope to give it optimal protection and because it’s patented  we’re the only ones to produce this defence in this way. Steel wire can be treated it in a much rougher way than synthetic fibre rope so therefore it needs the best protection possible. We’re continuously improving our protective jacket to increase the lifetime of the rope and we’re carrying out a great deal of R&D together with our fibre and coating suppliers.”

we’re the only ones to produce this defence in this way. Steel wire can be treated it in a much rougher way than synthetic fibre rope so therefore it needs the best protection possible. We’re continuously improving our protective jacket to increase the lifetime of the rope and we’re carrying out a great deal of R&D together with our fibre and coating suppliers.”

Elaborating further on OTS’ range of products, Jan says: “We mainly produce products made from dyneema fibre as that fibre has a unique combination of strength and weight. The weight is only 15 per cent of an equally sized steel wire yet the strength is equal to it. In the long run it is definitely more cost effective to use dyneema and it’s less risky for equipment as well, so increasing safety becomes a factor. Our overall task is to increase the strength of the rope using less fibre with a reduced diameter and reduce abrasion.”

OTS is currently in an excellent market position and has promising prospects for future growth, as Jan explains: “The seismic business is an important segment for us within the oil and gas industry. We’re involved in the towing and fishery businesses, both delivering products to fishing vessels and to fish-forming operators. We also deliver single point mooring systems to FPSOs and count the producers of tow andmooring systems as key customers as well. We contact the new operators within this field in order to market our products and we’re aiming to do business with companies in other maritime segments just so we can have more footholds in the marketplace.”

As well as expanding into other markets, OTS is planning to add more manufacturing facilities: “When we started the business we were involved in mooring lines but the production of the products from dyneema ropes has overwhelmed us in recent years. After we’ve expanded with new machinery and buildings we will start to look into this market again for the mooring of installations. I suspect that the demand for synthetic fibre ropes won’t subside though as it’ll become more difficult to work with heavy steel wires when the search for oil, which will continue for many years, goes into even deeper water.”

Continuing, Jan concludes: “We would like to see the company develop alongside the most important players that are supporting the oil and gas industries with handling equipment.”

OTS Offshore and Trawl Supply

Services: Fibre rope products