OWENS CORNING FOAMGLAS®

Energy savers

OWENS CORNING FOAMGLAS® DISCUSSES THE CONTRIBUTION OF INSULATION TO LONG-TERM THERMAL EFFICIENCY, ENERGY SAVINGS, AND THE REDUCTION OF CARBON EMISSIONS

About one-fifth of global greenhouse gas emissions comes directly from industrial sources. These direct emissions result from processes, including the combustion of fossil fuels for heat and power, non-energy use of fossil fuels, and chemical processes used in manufacturing.

The temperatures in these types of applications are often way above or below ambient temperatures and thermal insulation is therefore applied to pipes, equipment and tanks to reduce heat loss. This allows a gain in efficiency that reduces the energy use and the corresponding CO2 emissions.

Insulation is one of the easiest and most effective energy efficient technologies available today. Mechanical insulation systems are among the few manufactured products that save more energy than it takes to produce them. In research done by the National Insulation Association it was estimated that: ‘over a 20-year lifespan, mechanical insulation systems can save up to 500 times the energy that it takes for manufacturers to produce them’. If the insulated system is properly maintained, the savings from the investment continue throughout the life of the facility. A correctly designed and installed insulation system provides an excellent return on investment and immediate cost savings lead to rapid payback periods. Additionally, it is also a low-risk investment because the savings and the payback can be forecasted with a high degree of accuracy.

Industrial insulation experts agree that thermal insulation in industry is poorly maintained and that parts are not insulated sufficiently or not at all, creating thermal bridges, resulting in excessive heat losses and increased carbon emissions. Poorly maintained insulation does not only lead to increased energy costs and unnecessary emissions but can also contribute to higher thermal stresses which can lead to more frequent breakdowns that will negatively impact maintenance costs.

Recent studies by the European Industrial Insulation Foundation and the National Insulation Association have found that upgrading insulation systems can lead to reductions of energy loss up to 88 percent and a reduction of corresponding CO2 emissions with millions of metric tons per year1,2.

Findings showed that by insulating one standard DN150/6-inch valve operating at 150 °C (302 °F) with a standard and cost-effective insulation solution, about 10,000 kWh of energy can be saved. To get a better idea of the impact, the saved thermal energy for this one valve could charge the battery of a Tesla Model S electric car to drive more than 20,000 kilometers (12,427 miles) and saves carbon emissions equivalent of one and a half passenger vehicle driven for an entire year.

Finally, both studies concluded that approximately 40 million metric tons of carbon emissions could be saved in both Europe and North America. To put into perspective, such a reduction of carbon emissions per year equates to adding 1.9 billion mature trees or removing 8.6 million passenger vehicles from the roads.

Long-term thermal efficiency

Long-term thermal efficiency

The key to having insulation systems in place that provide long-term thermal efficiency, is to choose materials that, even in demanding environments, offer reliable and consistent performance and keep their insulating properties over their complete lifetime.

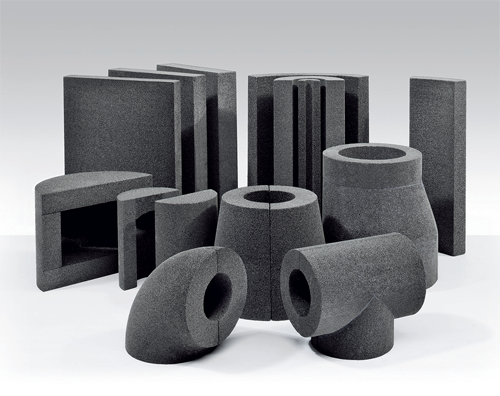

Owens Corning FOAMGLAS® cellular glass insulation is manufactured from sand, recycled glass and other abundant materials. These raw materials are mixed together and, with help of a chemical reaction, foamed to a block with millions of hermetically sealed glass cells. It is these cells that give FOAMGLAS® insulation its superior long-term thermal performance and moisture resistance.

A major internal factor that can negatively influence the long-term thermal performance of an insulation material is phenomenon called ‘aging’. Material aging takes place when the effective thermal conductivity changes throughout the lifetime of a material by the influence of time and environmental parameters, including temperature and moisture content levels. It can cause a chronic loss of thermal efficiency in insulation materials, resulting in lacking performance, energy loss and increased operating costs. FOAMGLAS® cellular glass insulation is not susceptible to gas diffusion and does not age over time, meaning that constant thermal efficiency and energy savings are provided throughout the life of the system. This minimizes the need for insulation replacement and helps support sustainable designs aimed for lower long-term, life-cycle costs and maximum efficient use of energy.

The largest external threat to an insulation system’s thermal efficiency is the absorption and retention of moisture in liquid and vapor form. Moisture, usually as water, can increase heat flow which will consequently lead to an increase in energy consumption and, consequently, higher overall operating costs. Industry studies have noted that open-cell insulating materials can see up to a 23 percent increase in thermal conductivity following a one percent increase in moisture3.

The most practical approach to long-term efficient insulation systems that also provides the most economical lifetime performance, is the use of inherently low permeability insulations. One of the only service-proven materials with decades of in-the-field performance in this category is FOAMGLAS® cellular glass insulation. Its closed-cell composition is 100 percent impermeable and highly resistant to moisture in vapor form. This overall moisture-resistance allows retention of its original insulating value without reduced thermal performance for many decades. This limits excessive heat losses, reduces carbon emissions and leads to lower life cycle costs for your installations.

1 EiiF – The insulation contribution to decarbonise industry (2021)

2 NIA – Mechanical Insulation Maintenance and Upgrade: The Annual Impact (2016)

3 GUSYACHKIN, A.M. et al., ‘Effects of moisture content on thermal conductivity of thermal insulation materials’, IOP Conf. Ser.: Mater. Sci. Eng. 570:012029, (2019).

Owens Corning FOAMGLAS®

www.foamglas.com/en-gb

www.owenscorning.com