Petronash

The full package

Established at the turn of the millennium, Petronash approaches the oil and gas industry with a mission to enhance its clients’ performance and productivity.

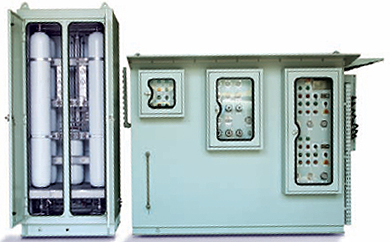

The business was incorporated to deliver services before diversifying into a full manufacturing unit in 2003. Today Petronash is known globally for manufacturing high quality equipment essential for the oil and gas industry, including wellhead control panels, chemical injection skids, wellsite packages and instrument control panels at its modern manufacturing facilities located in Jebel Ali, Dubai; Houston, US and new base in Dammam, Kingdom of Saudi Arabia (KSA), due to begin production by June 2015. Furthermore, the global presence of Petronash is maintained by its headquarters in the Jebel Ali Free Zone, Dubai supported by offices in Qatar, Abu Dhabi, Oman, Milan, India and Malaysia.

Petronash has been highly successful in responding to the changing needs of the oil and gas industry and employed a strategy of ensuring that it has bases close to its clients in areas of rapid growth and high activity. Commenting on the company’s move and continued growth in the US for example, managing director Mr. U.M. Rao reveals: “The US market has huge potential. We have established a base in Houston, which is known to be the Mecca of worldwide oil and gas business and also grants us access to the markets of Canada, Mexico and South America. The new manufacturing facility in Houston, Texas is as big as the company’s facility in Jebel Ali. It has all of the state-of-the-art automation equipment required to turn out the fabrication of goods very quickly. As the facility was nearing completion, we secured orders from Philips within the US as well as Exxon and Shell operating in West Africa. Production of these orders has already commenced and is progressing well.”

Further orders that highlight the global scope and scale of the projects delivered by Petronash include ventures with ONGC India where Petronash was able to execute a large turnkey project, supplying and replacing wellhead panels on 35 different offshore platforms consisting of 417 wells. All of the panels were replaced without the need of costly downtime or production interruption. Additionally, Petronash is the only company to have successfully executed three back-to-back Khuff Gas Chemical Injection projects for Aramco, which involved 255 skids with all delivery times reached within the agreed timeframe.

“Our multi-discipline expertise allows Petronash to innovate products, which in turn reduces downtime and enhances production for our clients,” Mr. Rao explains. “For example, the company’s recently developed wellsite packages and modular skids reduce the amount of time required to start production from wells following the completion of drilling, enabling quick revenues to  productions companies. This package also allows the client to deal with one vendor rather than manage multiple companies, eliminates site works and reduces production interfaces.”

productions companies. This package also allows the client to deal with one vendor rather than manage multiple companies, eliminates site works and reduces production interfaces.”

As the company continues to grow and expand, Petronash will ensure that it maintains a market-leading product portfolio that caters to the strict requirements of the oil and gas sector. As such the research and development of new products remains vital to the business. “Innovation and research and development play a very important role within any organisation in keeping up to date with technology and for diversification,” Mr. Rao says. “Petronash has a separate R&D division within Petronash Engineering in Chennai, where new products are continuously developed and tested.”

In tandem with the development of new products and services, Petronash works to ensure that it invests in its workforce and production processes to support the business as it continues to expand, as Mr. Rao elaborates: “Global expansion and a growing workforce go hand in hand. While we have continuously focused on increasing the company’s workforce in line with expansion, we have also invested in automation processes and technology to keep the reliance on manpower to a minimum and increase product quality. Petronash also operates a training department in Dubai where training for all new global recruits is provided.”

With a strong global footprint and continued investment in its manufacturing facilities, processes and workforce, Petronash has developed a truly global service offering and earned a reputation as a reliable partner within the oil and gas industry. As the company moves into the future it will seek to build on its current success and continue to engage with existing clients as well as new customers over the coming years. “With our wellsite packages and modular skids accepted by Aramco, there is a lot of potential business expected from these products and we are also expecting several other projects over the next few months,” Mr. Rao concludes. “We intend to market wellsite packages to other onshore companies worldwide and also diversify into the EPC business, especially for offshore clientele. In five years time we intend to position ourselves as an established EPC contractor with most of our package offerings coming from Petronash manufacturing units.”

Petronash

Services: Engineering and manufacture