Propane’s role in the clean energy movement

The clean energy movement is continuing to build momentum, encouraging business owners, logistics managers, homeowners, construction crews and farmers to search for scalable, clean energy sources that won’t break the bank.

As more companies adopt sustainable practices and look to reduce their carbon footprint, it’s important to consider the energy sources being used to power equipment every day.

Popular for its versatility and reliable power, propane has been essential to a variety of industries for more than half a century because it’s clean, readily available, and high performing. Also known as liquefied petroleum gas (LPG), propane is a nontoxic energy source that can be used on its own, in innovative blends, or alongside other energy sources such as wind and solar.

Propane’s footprint

Propane has been a mainstay in material handling, construction and agriculture industries for decades, safely powering a wide range of applications such as forklifts, generators, vehicles, and more.

Internal combustion engine (ICE) vehicles powered by propane maintain consistent power output, comparable to diesel variations, while reducing harmful emissions. For example, in recent real-world studies, propane-powered port tractors are proven to be up to 99 percent cleaner than existing diesel variations. Additionally, today’s propane autogas engines are 90 percent cleaner than EPA standards and reduce nitrogen oxide (NOx) emissions by 96 percent compared to the best-in-class clean diesel engines.

Propane is also ideal because it has a scalable, yet compact refueling and storage footprint with minimal infrastructure upgrades needed. With customizable contracts available in most areas, users can work with their local propane supplier to coordinate refueling schedules.

Propane is also ideal because it has a scalable, yet compact refueling and storage footprint with minimal infrastructure upgrades needed. With customizable contracts available in most areas, users can work with their local propane supplier to coordinate refueling schedules.

From propane cylinder storage racks for forklifts and mowers to on-site and mobile refueling options, propane is meeting a wide range of energy needs without costly infrastructure. Not only does propane make the refueling process simpler, it’s easier to achieve environmental regulations with new innovations in propane technology such as renewable propane.

Advancements in technology: renewable propane

Renewable propane offers the same benefits as conventional propane – reliability, portability, and power – but with the added benefit of reduced emissions compared with other energy sources.

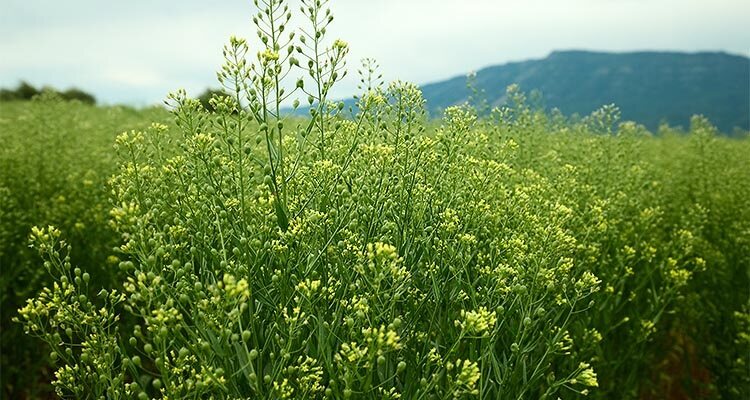

Renewable propane is made from a variety of renewable feedstocks, including camelina plant oil, vegetable oil, animal fats, used cooking oil, soybean oil and animal tallow. At the point of combustion, renewable propane’s carbon intensity – the carbon emitted for every unit of energy it produces – is four times lower than conventional propane and five times lower than diesel, according to research by the Propane Education & Research Council.

There are more than 4.5 million gallons of renewable propane produced every year. While it is sometimes used by itself as a vehicle fuel, renewable propane is also used for power generation in microgrids and off-grid electric vehicle charging units, providing an opportunity to reap the low-carbon benefits of the energy source.

A future with propane

Within the next few years, 100 million gallons of renewable propane is expected to be available, with a total potential of 300 million gallons in the next decade.

In fact, by 2050, renewable propane could meet half the world’s demand for non-chemical propane, according to the World Liquid Gas Association. The push for cleaner liquid fuels, such as sustainable aviation fuel and renewable diesel fuel, will lead to a sharp increase in renewable propane production.

Its ambitious growth can be attributed to emerging research on renewable propane production. One of the latest production methods is to use the oil found in camelina seeds. Camelina has one of the lowest carbon scores, with studies showing it can reduce greenhouse gas emissions by up to 60 percent. Because camelina is not a food crop, the production of camelina as a renewable feedstock is highly scalable, allowing for production to ramp up quickly as more adoptions take place.

Propane is also ensuring access to reliable power. Main power grid failures are inevitable, but standby, backup, and mobile power generation solutions keep families and businesses running without interruption to ensure safety and resiliency.

Kicking in within seconds, propane generators ensure minimal, if any, disruption in heating or cooling, lighting, refrigeration, smoke detectors, and other critical building systems.

Propane generators are 98 percent cleaner than diesel-fueled equivalents, keeping the air quality clean and reducing exposure to dangerous fumes. Plus, propane does not degrade over time and is always ready at a moment’s notice.

Additionally, towable and standby generators are scalable options to take power wherever it’s needed. Currently, electric vehicle providers use propane towable power generation units to recharge electric vehicles for test drives and in areas the infrastructure isn’t readily available. Mobile generator units are also ideal for power providers and emergency responders to utilize during extreme weather to keep communities safe and essential utilities functioning.

As we continue down the path toward zero emissions, it’s important to keep available resources like propane top of mind to significantly reduce emissions and achieve a low-carbon future.

By Gavin Hale

Gavin Hale is the director of product development and power generation at PERC.

About PERC: The Propane Education & Research Council is a nonprofit that provides leading propane safety and training programs and invests in research and development of new propane-powered technologies. PERC is operated and funded by the propane industry. For more information, visit Propane.com.