Maximizing Productivity: ProPure’s Solutions for the Oil and Gas Industry

Pure quality

ProPure is a supplier of key process technology and serves the oil and gas industry on a global scale, primarily subcontractors and oil operators.

As a leading provider of environmentally friendly purification technologies, it has established a solid reputation for providing technical services and equipment. ProPure’s ability to translate its innovative thinking into practical solutions provides leading companies in oil and gas with direct results in reducing operating expenditure.

Based in Norway, ProPure was founded in 1999 by Framo Engineering AS (FE) and StatoilHydro ASA under the name Framo Purification. The technology development initially began with FE, a  company with a long tradition of supplying technological solutions to the offshore oil and gas, and marine industry. In 2002, the business became 100 per cent Statoilowned and two years later all shares were transferred to Pure Process Solutions AS (PPS), a holding company jointly owned by StatoilHydro ASA and Hitec Vision business Energivekst. The aim was to rapidly grow into a major supplier of advanced process technology for the oil and gas industry, and in 2006 CTour Process Systems AS was merged into ProPure AS and the two companies, which had worked together in the commercialisation of CTour technology, joined forces to operate as ProPure AS.

company with a long tradition of supplying technological solutions to the offshore oil and gas, and marine industry. In 2002, the business became 100 per cent Statoilowned and two years later all shares were transferred to Pure Process Solutions AS (PPS), a holding company jointly owned by StatoilHydro ASA and Hitec Vision business Energivekst. The aim was to rapidly grow into a major supplier of advanced process technology for the oil and gas industry, and in 2006 CTour Process Systems AS was merged into ProPure AS and the two companies, which had worked together in the commercialisation of CTour technology, joined forces to operate as ProPure AS.

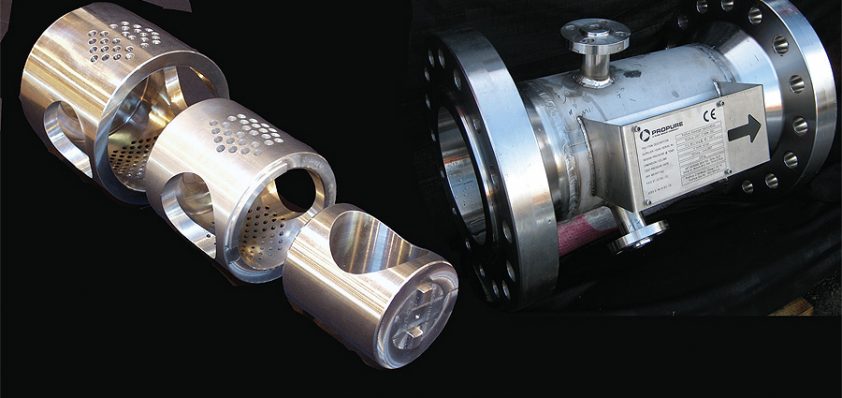

Of ProPure’s business, head of product development Harald Linga says: “We have patented technologies for the treatment of water, oil and gas. The key component is ProPure contactors, essentially mixer units, injection mixers and remixers. We obtain very high mass transfer rates with these components and our main strength is the performance of our processes. For water treatment we deliver the CTour Process, a technology for treating produced water with very low discharge of oil. Typically for installations, we’re in the range of one to two ppm of oil in water. We operate by combining our technology with commercial separators and improving the performance of the separator units.”

The majority of mass transfer operations conducted in both the oil and gas, and refining industries involve direct contacting between gas and liquid or two immiscible liquids. Although co-current contactors have found applications, the potential of efficient cocurrent contacting devices has yet to be exploited. ProPure has, through years of methodical development, established unique competence in the understanding of mass transfer applications pertinent for gas, oil and water treatment unit operations.

ProPure’s products have proved indispensable to many high-profile customers and the organisation is currently developing its services for new markets, says Harald: “StatoilHydro has been an important customer and we deliver to business such as ConocoPhillips, Total and BP. We’re working intensively in the Middle East and have a pilot set-up running for de-salting crude oil in Saudi Arabia. We’ve delivered the ProSalt unit that is a combined injection and remixing unit where fresh water is introduced into crude and mixed in order to coalesce with entrained salt water droplets in the crude, and we’re designing this process with improved separation characteristics of the two-phase watercrude flow. We can undertake this de-salting mixing with much lower pressure drop than commercial technologies.”

In terms of ProPure’s activities, its treatment processes vary considerably. “We promote three commercialised products,” reveals Harald. “Our CTour process removes dispersed oil and dissolved hydrocarbon contaminants from produced water by means of produced condensate. It’s the only cost effective process that removes both dispersed oil and highly toxic dissolved aromatic components for large volumes of produced water. ProPure has installed many water treatment applications that are accumulating field experience – we treat twothirds of the produced water in the North Sea on the Norwegian continental shelf.

“Our scavenging technology removes H2S from gas or liquid in the pipeline and we’ve delivered approximately 35 of those units worldwide. The advantage is that we can do the job with typically 30 per cent fewer chemicals spent, and the technology can be used for removing trace components in gas as well as injecting different types of production chemicals into the pipeline. With oil treatment, ProPure mixing technology offers, among other benefits, improved oil-water separation performance, lower chemical consumption and reduced environmental impact.”

treatment, ProPure mixing technology offers, among other benefits, improved oil-water separation performance, lower chemical consumption and reduced environmental impact.”

Harald says that being so closely affiliated with the operating companies has led to co-operative work being undertaken and ProPure plans to exploit its strong position in the market by expanding its scope: “We have a joint industry project with StatoilHydro, Total, ConocoPhillips and Chevron using a ProPure contractor for gas dehydration and we want to achieve a more compact process, which is particularly attractive offshore. In terms of current projects, we have ongoing activities with produced water treatment and need to expand due to the great deal of interest shown in our technology. The field in general is becoming trickier so new technology is needed in the interests of being economical.

“As part of our expansion, we’re opening an office in the Middle East this year and our ProSalt technology, a mixer solution for desalting crude oil is in particular targeted towards that region. By becoming part of PureGroup, ProPure is one of three central companies, which has led to a more open co-operation with our sister companies – and that includes commercial technologies marketed by ProSep in Houston. We have fabrication facilities in Houston and our sister company PGAP in Kuala Lumpur, and we’ll promote TORR coalescer units for produced water treatment.”

In moving forwards, ProPure wants to provide packages that meet all its clients’ needs, as Harald explains: “Our goal is to be renowned in the treatment equipment market and improve the quality of both produced water and crude oil. At present we deliver licences, key process equipment and contactors but in the future we plan to deliver complete packages.”

Propure A/S

Products Purification equipment for oil, gas and water