RAM Tubulars

Plans in the pipeline

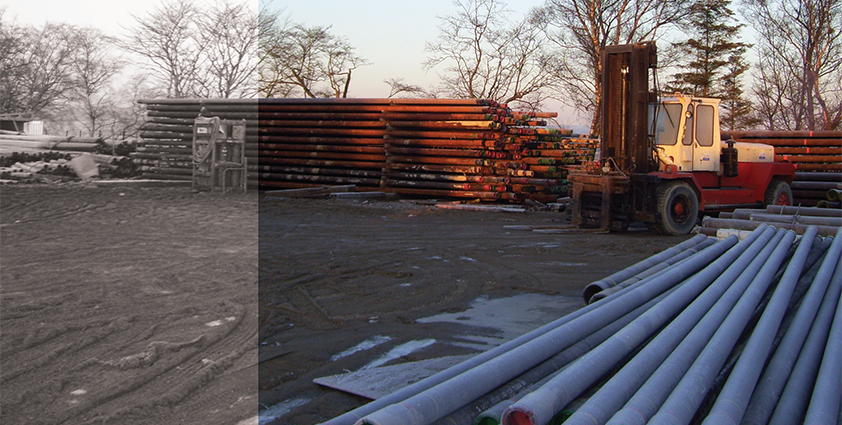

Established in Aberdeen in 1994, RAM Tubulars works alongside the oil and gas industry to recycle and develop used and surplus piping materials.

Whilst its early operations were exclusively within the casing and drill pipe market, RAM Tubulars has since expanded its activities to cover various other scrap and junk materials as well. Today, the company holds various long-term contracts with many major operators working in the North Sea, including the likes of Shell and Halliburton.

Jim Stewart, managing director of RAM Tubulars, elaborates upon the company’s continued expansion: “It very quickly became apparent that our experience gained in working with the oil industry to provide full documentation trails for recycling used tubing in the construction industry would provide a new approach to an age old problem.

“Our approach to this industry was unique in its nature in that we placed much more emphasis on the HSE and environmental issues. Another of our strengths is our wide service portfolio and, although we have developed the safe removal and disposal of scrap and junk material, we have also continued to grow in the used tubing business.”

Whilst the company is currently based in Aberdeen, its continued growth has seen it garner worldwide trading experience. Today, the company regularly imports tubes not only from European countries such as Norway, Holland and Denmark, but also Canada, the USA and China.

Such developments have allowed RAM Tubulars to secure contracts with some of today’s major global players in the oil and gas market. These, in turn, have generated further growth for company, as Jim highlights: “Our initial success led to us being awarded the Shell UK contract for the North Sea. This then required a need to expand upon our facilities, so as to accommodate the logistics and environmental issues it brought. It soon after became apparent that we had now created enough spare capacity to increase our business ventures.”

Such developments have allowed RAM Tubulars to secure contracts with some of today’s major global players in the oil and gas market. These, in turn, have generated further growth for company, as Jim highlights: “Our initial success led to us being awarded the Shell UK contract for the North Sea. This then required a need to expand upon our facilities, so as to accommodate the logistics and environmental issues it brought. It soon after became apparent that we had now created enough spare capacity to increase our business ventures.”

This continued growth saw the need for RAM Tubulars to open a second facility in Rotheram, in 2008. Located off junction one on the M18, this site is ideally situated to take advantage of existing trade links whilst developing new business sales. The company has also installed a 50-tonne weighbridge at the site, and it is also in the process of upgrading the saw cutting facility to accommodate pipes of up to 36 inches.

Jim highlights the advantages triggered by the investments at Rotheram: “This storage and distribution facility has provide a great success in supplying tubes not only to the UK market but also to mainland Europe. It has been an important step in the development of the business to provide a distribution and stocking yard within a four-hour delivery radius for our main customer base. As the success of this service has built up we have added saw cutting which have further improved our service capabilities, which have been utilised by smaller rig operators.”

Through year-on-year investment, RAM Tubulars has also been able to further improve its main site in Aberdeen, ensuring that it is fully equipped with the latest technology. Included within this is the company’s material tracking system, as Jim highlights: “This was adapted to provide a full on-line audit trail showing weights and values backed up by the required documents to fully comply with environmental audits. This approach to share vital information and work alongside our customers is invaluable as we all work together in this new era of increased awareness and more open partnerships.”

The company’s philosophy of working closely with its partners is vital to its success, as Jim continues: “We work very closely with all our customers, and when purchasing from the Oil industry we provide a full service to allay their main concerns on the safe removal and compliance with duty of care and HSE issues. These obligations are taken very seriously and we continue to strive to improve all aspects of this important service and investments in training and IT solutions will ensure we do not rest on our laurels.”

RAM Tubulars will continue to operate in this manner in order to ensure it remains successful for many years to come, and it has various plans for the future. Jim concludes: “The main goal of our activities has always been to provide a recycling service for tubulars and related products from the oil and gas industry that will provide low-cost benefits to the construction and engineering industries. We are always looking at new areas, with future plans that will also see the full manufacturing of tubes for the micro piling and ground engineering industries.”

RAM Tubulars

Products: Recycled tubular materials