Anchored in Excellence: Ramnäs Bruk’s Superior Stud Link Technology

Chain reaction

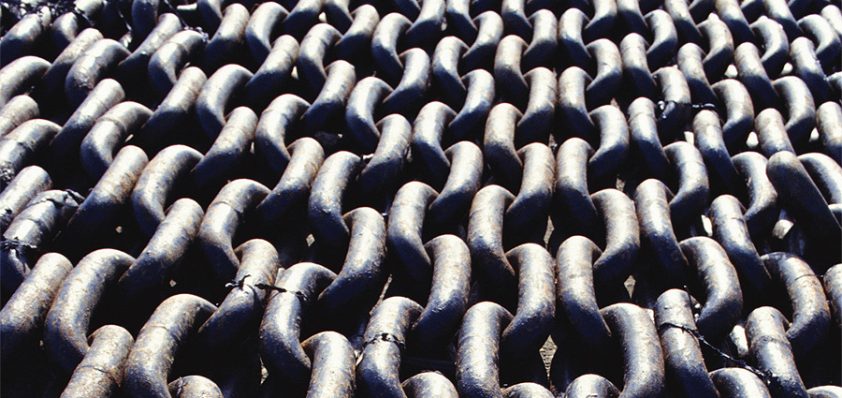

With the belief that no chain is stronger than its weakest link, Ramnäs Bruk has developed the best stud link anchor chain on the market.

Due to its unique manufacturing method of controlled stud expansion, the company’s chain is superior to all other stud link anchor chains available in the industry today.

Ramnäs Bruk has developed an asymmetrical stud that is carefully installed and expanded to exact tolerance. Established through years of research and development, the asymmetrical design of the stud gives equal stud footprints and also contributes to symmetric stress distribution throughout the whole link. This design combined with Ramnäs Bruk’s controlled stud expansion, has been  the standard method utilised in the company’s production process since 1991. The in-built ‘spring’ effect makes a tremendous difference in avoiding loose studs. The company’s experience over the years shows that the percentage of loose studs has been reduced from an average of 30 per cent to almost zero. As a result, the studs stay in place, resulting in a superior, safer chain.

the standard method utilised in the company’s production process since 1991. The in-built ‘spring’ effect makes a tremendous difference in avoiding loose studs. The company’s experience over the years shows that the percentage of loose studs has been reduced from an average of 30 per cent to almost zero. As a result, the studs stay in place, resulting in a superior, safer chain.

With nearly 40 years of experience working in the offshore sector, Ramnäs Bruk has been producing chains since 1876 in Ramnäs, Sweden. The company is a world-class manufacturer of high quality offshore chains that meet the highest quality standards of all the classification societies. Its grades, R4+ and R4++ give its customers a cost effective upgrade of the mooring cable system and keep modifications to a minimum.

Furthermore, the company’s grade R4EHS (similar to coming grade 5) offer greater strength but still keep the same link shape and weight.

Nils Nilsson, marketing manager at Ramnäs Bruk explains the company’s key strengths: “We have built a strong reputation at Ramnäs for providing extremely high quality products and services. We believe our customers are prepared to pay a little extra cost if they can be assured their products are of the highest possible standards. We also believe that every single contact our clients have with the company should reflect the quality of our products. We provide good customer service and act as a reliable partner for every customer.”

Throughout the whole company, Ramnäs Bruk holds the opinion that security of work, health and the environment are social responsibilities and should underpin all its activities. The company has always put high internal efforts and investments towards health, safety and environmental aspects. Ramnäs Bruk’s daily work reflects not only the Swedish Work Environment legislation, but also the internationally recognised standard OHSAS 18001.

The company’s main customers include, APL and Diamond Offshore, whom Ramnäs has supplied chains to for a number of years. The company believes that close co-operation with its clients, in addition to high HSE and quality standards, gives Ramnäs the edge over its competitors. Nils elaborates: “Developing close relationships with our clients is very important to us and allows us to provide flexible solutions to their requirements. We have a very good relationship with our main customer, APL and have recently developed a new chain accessory with them. They came to us with the idea for this and we provided them with the design and together we produced the new product.”

provide flexible solutions to their requirements. We have a very good relationship with our main customer, APL and have recently developed a new chain accessory with them. They came to us with the idea for this and we provided them with the design and together we produced the new product.”

The three most important factors when producing high quality chains are the raw materials, the welding procedure and the heat treatment of the chain. Ramnäs Bruk uses only steel from steelworks qualified and approved by classification societies and thoroughly inspects all materials upon arrival. For welding the links together, the company uses a linear production process and applies micro process control, whilst recording every individual flash butt weld. Lastly, during the heat treatment of the chain, the furnace and water temperature, pressure and chain speed are continuously recorded.

To further enhance the manufacturing process, the company invests a significant amount of money into its production facilities. Nils explains: “We have installed both an automatic magnetization machine for the non destructive testing and an automatic grinding machine, which grinds the links of the chain after the welding process. These make the whole process significantly more efficient and flexible, and also much safer for our employees. We have also added a new furnace, which has further enhanced our manufacturing facility.”

Nils concludes: “We aim to increase our production capacity in the future by about ten per cent every year, which I think we will be able to achieve due to the recent investment into new equipment. We would also like to increase our efficiency to enable us to remain competitive on a global scale. We predict that the market will be good until 2011 as demand for energy in the world is still increasing. There is a lot of investment into the building of offshore platforms and floating production units at the moment, which hopefully will continue to provide business for us into the future.”

Ramnäs Bruk AB

www.ramnas.com