Remora ASA is an oil service company, operating within the offshore sector

High expectations

It focuses primarily on providing the international market with innovative solutions for the offshore loading of oil.

The company was established in 2002 as a continuation of the Hitec group’s more than 20 years of experience in traditional offshore loading systems. The company has a head office in Stavanger, Norway, a branch office in Houston, USA, and has subsidiaries in Cyprus. The business has a highly competent team of personnel who deliver the company’s broad range of services.

Tore Lea, CEO of Remora, outlines the origins of the company and its latest development: “The company was established in 2002 as a subsidiary of Hitec, one of the leading suppliers within offshore loading systems. This was prompted by the development of a new generation of offshore loading concept, called the HiLoad technology. The company developed a new strategy in 2006 to realise the potential of the new technology by initiating the construction of the first HiLoad DP vessel. Construction began in 2006 at the Aibel yard in Haugesund, Norway and is now nearing completion.”

Tore Lea, CEO of Remora, outlines the origins of the company and its latest development: “The company was established in 2002 as a subsidiary of Hitec, one of the leading suppliers within offshore loading systems. This was prompted by the development of a new generation of offshore loading concept, called the HiLoad technology. The company developed a new strategy in 2006 to realise the potential of the new technology by initiating the construction of the first HiLoad DP vessel. Construction began in 2006 at the Aibel yard in Haugesund, Norway and is now nearing completion.”

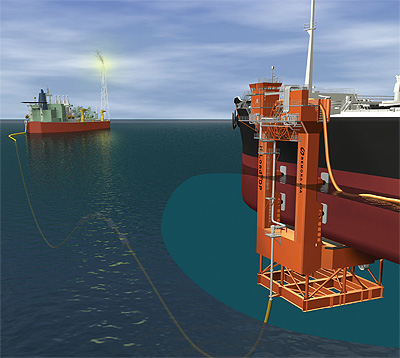

The company’s business model focuses on building, owning, leasing and operating HiLoad units. The technology was originally developed as an offshore loading system for crude oil. The core technology of the system is built around Remora’s patented HiLoad attachment system. The attachment principles used by the system are based on basic laws of nature – hydrostatic pressure and friction – and are combined with the common design features of all tanker vessels, which are a flat bottom with straight sides.

In this way, a HiLoad vessel can dock onto and provide station keeping to any non-dedicated tanker or barge, with no need for any modifications to the hull structure. The HiLoad units work simply by replacing the water and the related hydrostatic pressure already working on the tanker bottom over an area of about 600 square metres. This causes a robust friction force over 20 times larger than required to station keep the tanker in rough sea states. If more friction is needed, because of bad weather and local operational criteria, the attachment system is also designed to provide additional vacuum force.

The HiLoad systems can be adapted to function anywhere in the world, at any field installation, in any water depth, and under various harsh environmental conditions. The systems are L-shaped,  with slim towers to penetrate the wave zone. The HiLoads connect to other vessels in a similar sort of way to how a forklift connects to a pallet – the HiLoad moves underneath the vessel and lifts itself using a ballasting system. Its motion features together with its tolerance for harsh conditions make the HiLoad suitable for use in most offshore markets.

with slim towers to penetrate the wave zone. The HiLoads connect to other vessels in a similar sort of way to how a forklift connects to a pallet – the HiLoad moves underneath the vessel and lifts itself using a ballasting system. Its motion features together with its tolerance for harsh conditions make the HiLoad suitable for use in most offshore markets.

Tore explains the next steps in the development of the HiLoad system: “Being fully equity financed, we are quite flexible with our business model. The sea launch is at the moment expected in January 2009, followed by a commissioning and testing program. We will then conduct an offshore test, for which we will invite some of the leading oil companies – the operators – to actually be on site while we carry out the functional testing, which will include full operation. We expect that the success following this will initiate several new projects, incorporating the HiLoad technology.

“We believe very strongly in the potential of this technology, and the industry has also shown that it recognises the capabilities of the HiLoad system; the technology won the award for innovation at the Offshore Technology Conference (OTC) in Houston in 2004. The system was still in the development stage at that point, but the award shows that the pioneering technology behind it has been acknowledged by the offshore industry.”

Despite the current financial crisis and resulting difficult conditions within the oil and gas industry, Tore can see future opportunities for Remora: “We recognise that the oil price has dropped quite significantly. That will of course put high pressure on new projects and could also delay some projects that are currently underway. However, we provide a new system, which can simplify existing methods and in this way we believe that we will be able to reduce costs with our new technology. When the oil price is low that puts a higher pressure on the more conservative oil companies to implement new systems and processes in the interests of reducing costs.”

He concludes: “We have a future plan to grow within our core business, offering our services through our ship owning structure. This means we plan to build more HiLoad DP units. However, following the start-up and the gaining of operational experience with the first vessel, we also plan to develop the other applications of the HiLoad technology. Ultimately the economic crisis could also be an opportunity for our company, as we expect an increasing demand from the market place for methods and means of reducing future development costs, which we expect will pave the way for Remora and the HiLoad concept in the future.”

Remora ASA

Services Offshore oil loading solutions