Ropsley Group’s investments in machinery enable it to meet the demands of the British power industry

One of the largest independent groups in the UK’s power and industrial markets, Ropsley Group (Ropsley) is well positioned to provide a fully integrated and seamless solution. Its expertise spans steam boiler and pressure part design and engineering, through to manufacturing, installation, and ongoing repair and maintenance services for a variety of sectors. A year after our last conversation, we catch up with David Hayle, Group Managing Director, who shares insights into the latest developments at Ropsley.

“Last year, we acquired the historic business Green’s, and subsequently purchased the assets of a company called Heat Exchange Group Services, which we renamed HEGS PHE (HEGS). Since then, we have been actively exploring opportunities in the marketplace for both businesses. We have made significant changes, including relocating HEGS from the shared Wakefield facility with Green’s to a dedicated, modern site near the M18 and M62, close to the M180 junction. HEGS  primarily focuses on small-scale heat exchangers and plate heat exchangers all over the UK. It serves a variety of key clients in the chemical, offshore, and rail industries, including Rolls Royce, Ithaca Energy, and Cummins. We strengthened the management team at HEGS by introducing new systems, processes and personnel, enabling the business to thrive. The move has allowed HEGS to operate as a self-contained entity, alleviating the constraints it faced in the previous shared facility with Green’s in Wakefield. This transition has also provided Green’s with the opportunity to expand into the additional space,” he opens.

primarily focuses on small-scale heat exchangers and plate heat exchangers all over the UK. It serves a variety of key clients in the chemical, offshore, and rail industries, including Rolls Royce, Ithaca Energy, and Cummins. We strengthened the management team at HEGS by introducing new systems, processes and personnel, enabling the business to thrive. The move has allowed HEGS to operate as a self-contained entity, alleviating the constraints it faced in the previous shared facility with Green’s in Wakefield. This transition has also provided Green’s with the opportunity to expand into the additional space,” he opens.

In the same vein, Ropsley has implemented changes across all its companies to better align the individual businesses with the Group’s goals. “Over the past 12 months, Green’s undertook a significant restructuring exercise that included a thorough overhaul and deep clean of the workshop, realigning office buildings to enhance efficiency. In addition, we felt the business development had lost its direction somewhat, so following a re-evaluation of its core markets we are now focused on three key areas: the UK market, which is closely linked with our subsidiary, PJD; the Middle East; and the Marine market, where we have over 7000 Spanner boiler references at sea.”

Its sister company PJD, is a mechanical contractor focused on major power stations, industrial facilities, and energy-from-waste plants. The company frequently installs new components, many of which typically come from companies like Green’s, thus, the rationale for acquiring Green’s was to achieve vertical integration.

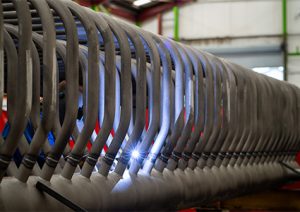

“Over the past year, we have been assessing what capability Green’s needs to meet the requirements of the Group’s UK clients, particularly those of PJD, and we are pleased to announce that we have invested around £1 million on what will be the UK’s largest Inconel machine,” David reveals. “This machine, which overlays boiler tubes with Inconel to significantly extend their lifespan, is important for the UK market as it helps extend the time between plant outages. We expect to begin production in early 2026 and subject to demand, have an option in place to buy a second.

“Additionally, we are upgrading a host of other machines in the facility to ensure everything is at the forefront of modern safety standards and wherever possible is laser-protected. Currently, in addition to the investment in our Inconel capability, we are evaluating the business case for a further £1 million investment in new machines. All-in-all, by the end of 2025, we anticipate having invested nearly £3 million into the Green’s business as a whole, investment which is crucial for meeting the specific needs of the UK market, which requires a comprehensive range of particular machinery in order for the Group to offer a full-service seamless capability, rather than just being able to handle one part of the process,” David elucidates.

Beyond the UK market, Ropsley is actively working to expand its presence in the Middle East. “As part of the Green’s acquisition, we also acquired the Intellectual Property and Trademarks of Hunt Thermal Technologies, another great British heritage brand which was in danger of withering on the vine. Hunt Thermal has a strong track record in the Middle East, where it has a large installed client base, so, led by Stewart Highett who has over 25 years’ experience in the region, we have dedicated significant efforts over the last six months to relaunch the brand whilst renewing and reinvigorating relationships with its former customers in the region. At ADIPEC, the world’s largest oil and gas expo which takes place in Abu Dhabi this November, we will be announcing an exciting new partnership with a high-profile organization in the Gulf, which we expect will further enhance our profile in the region with potential clients, especially the major global oil companies, such as ADNOC and Saudi Aramco, to name but a couple,” David reveals.

region. At ADIPEC, the world’s largest oil and gas expo which takes place in Abu Dhabi this November, we will be announcing an exciting new partnership with a high-profile organization in the Gulf, which we expect will further enhance our profile in the region with potential clients, especially the major global oil companies, such as ADNOC and Saudi Aramco, to name but a couple,” David reveals.

The third aspect at the heart of Green’s’ growth strategy over the past year is the marine industry. “Within the marine boiler sector, Green’s has over 7000 floating reference plants utilizing its proprietary technology on Spanner boilers, this is a sector the new management are keen to dive into explore further to understand how we can contribute going forward. Again, we are dedicating significant time and resources in examining the marine market and reconnecting with former clients.”

During this busy year of acquisitions and integration, maintaining a cohesive culture across all companies has been a task of its own. “We brought together five businesses, which resulted in a collision of cultures, each with different approaches. However, the underlying culture we are fostering across all companies is our ‘can-do’ attitude. By following PJD’s world-class lead we are ensuring that everyone adheres to the highest health and safety standards, this is our benchmark, and everyone at Ropsley is expected to meet it.

“Our collective goal is to ensure the group’s success, not just financially, but also as a great place to work. At Green’s, for example, we have refurbished all the offices, down to making small changes like upgrading the coffee machines! We have extended the same benefits from PJD to everyone at Green’s, including an extra day off for their birthdays. Our culture is all about creating an enjoyable and aspirational workplace. Furthermore, we currently employ around 300 people, and are maintaining our goal of having ten percent as apprentices, meaning today we have more than 30 apprentices in our program at any given time which is managed by our group training provider ACTTnow, and will provide us with that skilled pipeline for the future,” David concludes.

Ropsley’s strategic acquisitions, investments, and collaborative culture position it as a leader in the power and industrial markets, setting the stage for continued growth.